Polished Concrete Floors Greenwash

GBE > Encyclopaedia > Code > Greenwash > G#737 N#759

Polished Concrete Floors Greenwash

About:

Introduction to polished concrete.

I hope that this fulfills all of your requirements.

I have noted below some constructed statements, as well as those already listed within both our brochure and within Lafarge website listings. Although it would have to be said that the new concrete application, Artevia polished as attached, basis its environmental approach as being sustainable as appose to its production being pure environmentally friendly, having researched this somewhat it is comparable to most other floor finish and floor constructed products, more over in most cases concrete is used anyway just hidden by an applied surface, so the grinding and polishing of such surfaces stands good grounds for consideration.

Polishing existing concrete.

The process itself consists of simply grinding the paste coat laitance from the surface of the concrete floor, to remove any undulations and expose the natural beauty and colours of the aggregate that until now has been hidden below the surface.

A densifier/cure is applied and left overnight to soak into your floor ready for the final stages.

Our polished concrete technicians will now commence with what we think is the truly sparkling phase of the process, with the use of HTC’s brochure attached, patented, diamond / resin bonded polishing segments which can give your floor a whole range of stunning and practical finishes.

Polished concrete designs brochure attached.

Environmental

Our system enjoys one of the lowest embodied carbon (CO2) footprints available for a finished floor and we are currently undergoing evaluation in our aim to further reduce our carbon rating.

Top Trumps you win. If you focus on one issue and ignore all the other issues you will always find a characteristic that is better than others.

Look at any traditional floor covering and something as small as a single kilo of self leveling epoxy uses 50 kWh/m2 of energy just to produce.

Top Trumps you win. Choose the worst to compare yours with.

We also actively promote the use of alternative compounds to cement in concrete (PFA, Pulverised Fuel Ash, Fly Ash and GGBS) which can produce a reduction in CO2 by up to 48% and are happy to advise on alternative mixes.

Top Trumps you win, Throw in some polluting materials, ignore the pollutants and focus on the CO2

Top Trumps you win, add GGBS and ignore the CO2 of steel making.

Research & Innovation

Lafarge R&D teams work to develop environmentally friendly products in order to:

- decrease CO2 emissions in cement production

- conserve natural resources

- use a higher proportion of recycled raw materials in the production process

- create value-added products for sustainable construction,

- improve health and safety for employees and subcontractors, whats in it?

- optimize the performance and uses of Lafarge products.

Artevia brochure attached.

I know that Lafarge circulate a lot of material in this area, but if you choose to get a direct opinion and associated information.

Final attachments. A group of images representing some examples of finished work.

Please call me if you think I can help with details to re-edit the above into something that the CFJ magazine can use.

Needs a lot of work

Assuring you of our best attention at all time.

Polished Concrete Designs Ltd. Unit 12, Blue Chalet Industrial Park

London Road, West Kingsdown, Kent, TN15 6BQ

T 01474 854 500 F 01474 854 600

E John@polishedconcretedesigns.co.uk W www.polishedconcretedesigns.co.uk

Contact: John Barry I.Eng

M 07739 711445

Lafarge Research and Development.

Contact: Emma Hines

M 07803 953935.

Polished Concrete Floors Greenwash

GBE look at all aspects of an element and don’t just consider low carbon footprint at the expense of functional performance and user requirements.

Polished Concrete Floors

When asked to give an opinion on the merits or otherwise of a polished concrete floor finish BrianSpecMan wrote:

- Lots of greenwash and badly written marketing

- Yes it needs a lot of work.

- A lot of information about other stuff in the company’s or supplier’s ranges unrelated to this floor hardener.

If you expose the concrete and show it off:

Costs:

- You need to consider cost, its made of concrete, but does not mean it’s cheap.

- Polished Concrete Floor dematerialises the floor (removes other finishing material completely) but may be adding more below and definitely more actions and ingredients on top, making the concrete floor surface more expensive.

- A fair-faced concrete will invite a higher labour rate than tamped or floated and covered

- to achieve highest quality consistent appearance concrete

- And extra processes to make it look good.

- You need to strengthen the concrete floor against foot traffic wear with some of the following:

- Grinding the surface laitance off to expose and grind stronger aggregates and stronger matrix materials below the surface

- a coating of resinous stuff (expensive, synthetic ingredients, non-renewable, high embodied energy/carbon, off-gassing, VOCs, hazardous waste?),

- add stronger aggregates e.g. granolithic chippings (where from?) or a monolithic granolithic topping

- or impregnate the floor with stuff (expensive, synthetic ingredients, non-renewable, high embodied energy/carbon, off-gassing, VOCs, hazardous waste?)

- Other accessories: movement control joints and threshold strips, power distribution, (expensive, high embodied energy/carbon, labour intense, hazardous waste?)

Performance:

- You exposed its thermal mass, which is a bonus, only if it is exploited,

- The Curve Arts Theatre in Leicester has a concrete polished floor but so much solar protection that no sun gets in nor heats it up, it gets heated by M&E plant and/or the presence of people.

- It needs to be on top of waterproof thermal insulation and gas/damp proof membrane: high embodied energy and carbon;

- Having the floor at a different level to surrounding floors may lead to a thermal bridge that needs to be considered and insulated accordingly

- Polished Concrete Floor is unlikely to include under floor heating, other means need to be considered

- Polished Concrete Floors have an acoustic influence on the space and surroundings

- no acoustic absorption,

- high acoustic reflection,

- longer reverberation time,

- impact noise,

- noise transfer through floor, to other spaces

- may need acoustic isolation joints

- Object falling on Polished Concrete Floors are vulnerable to breakage rather than bounce

Appearance:

- Could be beautiful

- The Curve Arts Theatre in Leicester has a polished concrete floor that under the lighting it receives could be anything: resin, rubber, PVC or linoleum its difficult to tell.

- It does not look special

- Polished surfaces and distant lighting will emphasis the swirls of the power-float/grinder left in the concrete surface best left matt to hide them

- You need to have interesting aggregate/binding to be worth showing off

- Recycled aggregates

- recycled concrete aggregate from the site prior use may be suitable

- may not be beautiful to the designer

- may need to be selected

- Special aggregates may need to be brought to the site

- marbles from italy?

- Fancy aggregates from where?

- more money?

- Concrete drying shrinkage needs to be controlled and large floors must be broken up with movement control joints,

- The layout of movement control joints need to be considered as a design issue and not left to chance

- Grinding floors with control joints is not simple, so often cut afterwards and then filled with:

- load bearing sealants (synthetic ingredients, non-renewable, Off-gassing, VOCs, hazardous waste?)

- or strips of metal or plastic. (high embodied energy and carbon, non-biodegradable)

- threshold strips at perimeters: metal or plastic. (high embodied energy and carbon, non-biodegradable)

Materials:

- They promote but do not require cement substitution

- so may be made of OPC Ordinary Portland Cement

- (2% of UK CO2 production or 8-10% of global CO2 production)

- but will always have a proportion of OPC (80-30% depending on application and adoption)

- PFA Pulverised Fuel Ash

-

- Residue from Coal fired Power Stations

- CO2, other pollution, See TRASHED FILM

- spherical, glass like,

- aggregate and cement replacement,

- desulferisation gypsum by-product to avoid acid-rain from flue gases mixing with weather

- (yes, correct spelling see OED it was changed)

- Fly Ash

- Residue from furnaces

- See below See TRASHED FILM

- GGBS Ground Granulated Blastfurnace Slag Cement

- (waste from UK steel making,

- High embodied energy and potentially high embodied carbon,

- cementitious,

- slower set,

- same ultimate strength,

- Low carbon (only if you discount the steel making impacts),

- suitable with recycled glass aggregates (no alkali-silica reaction);

- warmer colour than OPC cement if its still visible

- Removes laitance (water diluted cement matrix on top surface) and flatten out surface tolerances

Other impacts:

- Need to consider diamond grinders

- if industrial diamond and made in laboratories in the UK or EU might be okay,

- very high embodied energy

- if obtained naturally need to consider the social and environmental pollution associated with diamond extraction

- Need to consider the electrical energy or fuel input to the grinding and polishing kit

- Need to consider the waste water and ground material dust removal and appropriate disposal

- The alternative is a second hand softwood scaffold board tamped across the surface by two men eating 3 shredded wheat for breakfast

Life Cycle Assessments:

- If you have chosen to use Polished Concrete Floor then an LCA will tell you how bad the floor is.

- Do not use a generic LCA to judge it, use a Product Specific LCA with all the components included

- Generic LCA will let you know roughly which is the least bad type of floor when compared to another type

- Looking at individual impacts (e.g. CO2 or embodied energy) alone just plays Top Trumps.

- “Being less bad is not good” William McDonough C2C

FlyAsh

on the subject of fly ash Alan Best RIP wrote the following 2011:

- “Coal Fly Ash Class C has worked well as an infill material for the Shaw EcoWorx carpet and carpet tile backing system.

- This is a bi product of coal combustion at electrical generating plants and is derived from particles captured from the flu gasses in electrostatic precipitators.

- Around 40% of recovered fly ash has been recycled to supplement Portland Cement in concrete production and has thus produced major savings in energy and CO2 emissions.

- Fly Ash C is not considered or treated under regulation as a hazardous waste stream, although it contains trace concentrations of heavy metals and other substances that are known to be detrimental to health in sufficient quantities.

- Potentially toxic trace elements in coal include arsenic, beryllium, cadmium, barium, chromium, copper, lead, mercury molybdenum, nickel, radium, selenium, thorium, vanadium, and zinc.

- Although no regulatory controls have been implemented there have been a number of concerns expressed by environmental groups regarding the potential for damage to human health and the environment from the processing, handling and storage of this material

- In December 2008 the collapse of an embankment at an impoundment for wet storage of fly ash at the Tennessee Valley Authority‘s Kingston Fossil Plant resulted in a major release of 5.4 million cubic yards of coal fly ash, damaging 3 homes and flowing into the Emory River.

- Cleanup costs may exceed $1.2 billion.

- This spill was followed a few weeks later by a smaller TVA-plant spill in Alabama, which contaminated Widows Creek and the Tennessee River.

- These events caused Shaw to review its use of the Coal Fly Ash C material and to seek a suitable alternative.”

Alan Best 2012

See TRASHED FILM All Furnace ash is polluting, Fly ash is much worse than bottom ash.

© GBE GBC GRC GBL NGS ASWS Brian Murphy aka BrianSpecMan ****

26th January 2013 – 29th January 2024

Polished Concrete Floors Greenwash

About:

GBE CPD

- Greenwash (CPD) G#289 N#290

GBE Video

See TRASHED FILM All Furnace ash is polluting, Fly ash is much worse than bottom ash.

© GBE GBC GRC GBL NGS ASWS Brian Murphy aka BrianSpecMan ****

29th January 2024

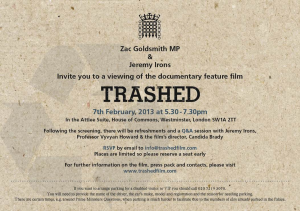

Images:

Trashed Film Invite 2013

© GBE GBC GRC GBL NGS ASWS Brian Murphy aka BrianSpecMan ****

29th January 2024