GBE Recycled Plastic Blockwork Q+A

GBE > Encyclopaedia > Code > Question+Answer > G#27567

GBE Recycled Plastic Blockwork Q+A

About:

GBE LinkedIn Discussion

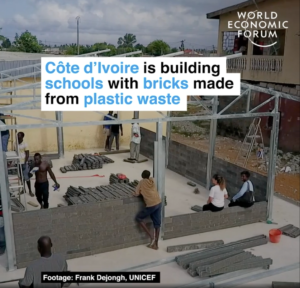

- LinkedIn Video posted by World Economic Forum

- Changing the lives of over 25,000 children.

- Read more: https://wef.ch/34nN4dL

- hashtag#education

- hashtag#environment

- George Crown ARCHITECTURAL VISUALISER / RIBA II 3d

Q1 Hi Brian do you mind sharing some thoughts about this?

A1 Reply to George Crown via Linked In

The response is more detailed in this article than on LinkedIn

Plastics in Crisis

- Whilst there are ‘plastics in packaging waste’ and ‘micro-plastics in the oceans’ problems and public awareness has been raised by Trashed Film, naturalist Richard Attenborough and others; it is finally seen as part of the greater Climate Emergency.

- Greta, Striking school children and on the 20th September 2019 adults alike will come out in protest against Governments lack of commitment to solving the Climate Emergency.

- Greater efforts are being made in supermarkets and public engagement is growing.

- Ocean clean-up projects are finally starting out on a mammoth task.

- Cleaning up the flotsam at the surface will be relatively simple, filtering the soup below the surface will be more challenging and cleaning the falling debris and sediment will be impossible.

- Dealing with the toxin covered (See Trashed) micro-plastics already in the food chain all the way up to mammals which are then eaten by humans, affecting foetus and feeding young via breast milk, is altogether more challenging.

- There is some merit in segregation, collection and recycling of plastics on land in some form or other.

- Without seeing all of the manufacturing processes, judgements can’t be substantiated but here are some of my concerns.

Plastics Bacteria Pathogens and Dioxins

- The plastic waste illustrated is already highly polluted with everything bad, including festering food waste, bacteria, animal and human waste pathogens.

- If left to their own devices with all things in their favour bacteria could neutralise some of the pathogens and other bad stuff eventually, but favourable conditions will not be ever present.

- Bacteria and pathogens can adsorb to the surfaces of solid plastics

- Bacteria and pathogens can absorb into the pores of aerated plastic foams

- If the plastics are collected and not cleaned and melted without separating out the bacteria and pathogens, poured into the moulds and heated the bacteria may remain, partially encased and partially exposed.

- The heating process will kill some of the bacteria and pathogens and others may survive.

- The people this may help are probably heavily impregnated with bacteria, pathogens and toxins from handling and dioxins from burning some of the plastic waste, so may be immune to varying degrees, or more vulnerable!

GBE Checklist: Z50

- Capture the plastics before they become polluted

- Do not collect polluted plastics from rubbish dumps, flotsam (off water) and jetsam (wind blown)

- Plastics from the ocean may have concentrations of dioxins from dispersed smoke, landing on the oceans and adsorbed to the surfaces.

- Segregate the plastics

- Clean the plastics collected, take precautions with the cleaning water

- Especially avoid flexible PVC (plasticised and may contain high levels of phthalates)

- Avoid rigid U-PVC or PVC-U (unplasticised)

- Don’t burn any plastic especially PVC

- Never breath in toxic smoke from burning plastics especially dioxins from PVC

Recycling risks

- I remember a UK manufacturer experimenting using clean, segregated, recycled plastics as a resource to make building boards with foam core and hard skins

- Ink cartridges and other waste streams were considered.

- When medical waste was suggested, a difficult to deal with waste stream, my response was when the builder is cutting and drilling the board is she exposed to the medical waste pathogens?

- When she drills the hole and blows the drill dust from the hole does she get medical waste pathogens and drill dust back in her face, ready to be breathed in? “Don’t go there”.

Working with recycled plastics in construction

- Today I would add cutting plastics to size or to fit is challenging:

- Using a hot wire will generate fumes, some toxic including the worse from PVC, dioxins.

- Sawing any plastics will generate millions of micro-plastic particles, that will not currently be collected or vacuumed up, may be brushed up and sent to landfill or will find there way into the air, ground or watercourses, eventually to the oceans.

- Sawing any polluted plastic with help to disperse the pollution.

- Using a blade may be an ideal method, but challenging with bigger tasks.

Recycled Plastics blocks

- The Energy consumed melting the plastics and making the blocks may be considerable, adding to the embodied energy (making plastic from crude oil and re-melting) and embodied carbon (from the fossil fuel it is derived from and from energy for heating to melt the plastic, depending upon the fuel used).

- The schools are costing $14,000 some goes into the metalwork structure and roof, some to labour and some to the blocks, but there is very little information breakdown.

- It will be interesting to see what proportion goes to the plastic collection pickers and the energy to re-melt the plastics.

- The blocks may off-gas, plastics chemistry, bacteria, pathogens, toxins and dioxins?

- The colour, density, specific heat capacity and thermal mass of the blocks will offer some decrement delay, solar protection to avoid some overheating in the rooms but once they have reach saturation point they will emit heat inwards.

- Plastics when exposed to the sun and heated can hold on to the heat for some time and may be the source of blisters or burns if touched by bare skin.

- The plastics may be a source of radiant heat after sunset, if desirable and a problem if not.

Self-build with modular blocks

- The self-build aspect is appealing and all ages can join in, a whole single room building or a whole house in a day is also a potential benefit, including in emergency relief situations.

- Assuming they come apart easily, reclaim and reuse is possible, but easily dismantling may also be an aid to building theft.

- Modular construction like this, using stretcher bond, locking the perpend joints in the preceding course, needs a set of half length, corners, junctions, opening, closing, starting, stopping, lintel, threshold, sill components to go with it or there will be a need for metal framing or more cutting on site.

- The Modules or blocks need to be a suitable size to make appropriate sized openings without cutting.

Recycled plastics fire resistance?

- The video mentions blocks are fire resistant.

- And shows a sizeable chipped block, will its integrity be affected by chips like this?

- Never use a chipped unit in a wall that needs to be fire resistant.

- I wonder which fire characteristics have been tested, and if Fire resistance (BS 476 style) as we know it is the important characteristic?

- What about: Ignitability, Combustibility, Propagation, Surface spread of flame, flaming droplets, Smoke generation, etc. sound like they are more important, if exposed or if behind a lining.

- We know from Grenfell that plastics are fuel to a fire.

- Building schools with short emergency egress times may get over that problem.

- But large numbers of children in smoke filled spaces may turn into chaos and many may not find their way out.

- I wonder how they get the fire resistance/other properties?

- Aerated plastics will ignite very easily.

- Foil faced insulation should not catch fire but exposed edges will.

- No foil face means the plastic fuel remains available to the fire.

- Finishes with other fire characteristics may be applied but not presented in the video

- Solid plastics may be more difficult to ignite and keep alight.

- Some will ignite easily and some are very difficult to put out; as demonstrated by children’s plastic Halloween costumes catching fire and refusing to stay put out, reigniting with the retained heat and oxygen and off-gassing ignitable plastic fumes, leading to horrendous burns to wearers and to carers hands trying to put out the flames.

- Additives could modify the fire performance but the additives are often toxic themselves.

- People usually die from smoke inhalation and toxic gasses remaining in the lungs preventing oxygenation of the blood, rather than dying from fire.

- With plastics in close proximity to people they could die from fire, smoke and/or burning droplets.

- A one-roomed school may not need fire resistance, three rooms may require it.

- Fire resistant may not be an appropriate characteristic but I hope the other fire characteristics that are appropriate and applicable have been addressed.

- For the sake of the children.

© GBE NGS ASWS Brian Murphy aka BrianSpecMan *

8th September 2019 – 14th September 2019

GBE Recycled Plastic Blockwork Q+A

Images:

Video:

Go to LinkedIn page to see WEF video

Images:

© GBE NGS ASWS Brian Murphy aka BrianSpecMan *

8th September 2019 – 10th September 2019

GBE Recycled Plastic Blockwork Q+A

See Also:

GBE Sign Up

- GBE Membership (Sign-Up) G#23472

GBE Slogans

- Build Light Insulate Right Solar Tight (Slogan) G#2272

- Fabric First Materials First Performance First (Slogan) G#17243

GBE Q&A

Legend

- Statement No.: S1, S2, etc.

- Observation No.: O1, O2, etc.

- Question No.: Q1, Q2, etc.

- Answer No.: A1, A2, etc.

Pages

- Fire Resistant Staircases (Q+A) G#20881

GBE Checklist

- A38 Construction Waste Management (Checklist) G#1709 N#1611

- A38 Waste (Checklist) G#12806

- A39 Packaging Waste Management (Checklist) G#1712 N#1614

- A90 Performance Specification (Checklist) G#1715 N#1617

- F10 Brick/Block Walling (Checklist) G#1647 N#1561

GBE CPD

- Surveys Tests Analysis (CPD Lecture) G#389 N#390

GBE Lectures

- (21) Masonry External Walls (Lecture) G#2115 N#216

GBE Shop

- GBE Lecture (21) Masonry External Walls (Shop) G#11559

- GBE Issue Paper Overheating (Shop) G#10433

GBE Issue Papers

- Overheating (Issue Paper) G#145

© GBE NGS ASWS Brian Murphy aka BrianSpecMan *

8th September 2019 – 10th September 2019

GBE Recycled Plastic Blockwork (Q+A) G#27567 End.

Template: GBE Question & Answer (Template) Q#14864