GBE > Encyclopaedia > Product > Accessory > G#8714

Thermo-Pro® Thermo-Bead

Thermal Break to Window/Door Opening Jambs within EWI

GBE Blog > News

- 06/01/16: GBE Classify aded to 5 Thermo-Pro Accessories pages

- 06/01/16: GBE Blog > News and Slider added to header

- 06/01/16: Draft clauses posted in 5 Thermo-Pro Accessories pages

- 05/01/16: GBE Robust Specification 1st issue for comment,

- 30/12/15: 5 Thermo-Pro Accessories pages created

- 18/12/15: GBE Tabbed Accessory Page Template developed with 5 Thermo-Pro Accessories

- Click on scrolling images to get static, larger, crisper, whole images

- Click on Tab 6 Manufacturer’s Downloads to open documents

Thermo-Pro® Thermo-Bead

Thermal Break To Window/Door Opening Jambs Within EWI

Tabs with added * indicates it contains Accessory specific information

Thermo-Pro® Thermo-Bead

- Literature

- Application

- Accessory

- Installation

- Complete

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

Draft Information

INTRODUCTION

Cold Thermal Bridging in External Wall Insulation (EWI)

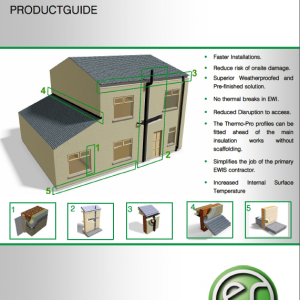

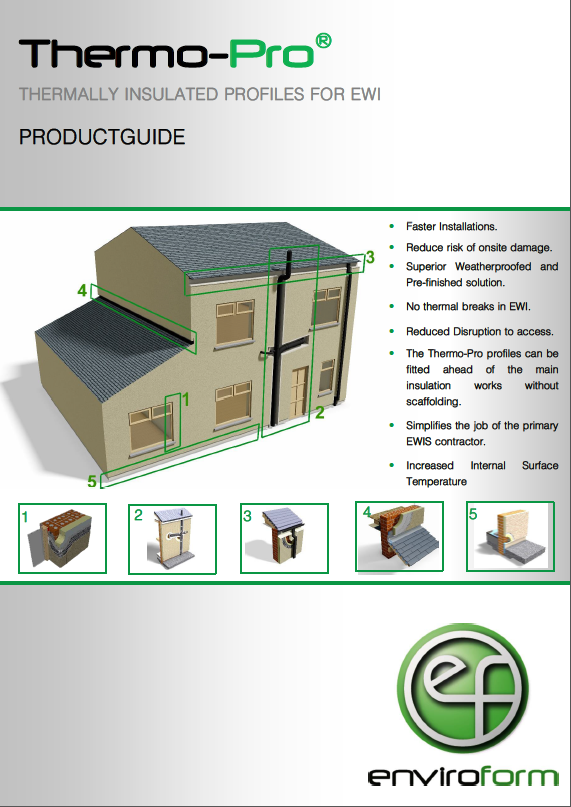

Enviroform Solutions Ltd. have developed a number of unique products using Aerogel thermal conductivity insulation combined with various materials, to tackle the issue of cold thermal bridging and weathering at key junctions when installing External Wall Insulation.

The Key Junctions in question addressed are:

- 1 Windows & Door: Reveals & Sills

- 2 Soil Pipes & Gate Posts / Fences

- 3 Eaves & Gutter: where little or no overhanging soffit exists

- 4 Lead Flashing Details: Bay windows to walls – Single storey beside two storey; EWI above pitched roof

- 5 Below DPMC Level: above ground level

Failure to identify and adequately deal with these cold thermal bridging elements can lead to

- A Increased heat loss from a dwelling compared with what was assumed determined during energy modelling.

- B The Risk of surface condensation or mould from lowered internal Surface temperature at or near the Thermal Bridge Junction.

- C Risk of mould growth from spores in surface condensation at or near the Thermal Bridge Junction.

By introducing the Thermo-Pro® Soil Pipe insulated profile the linear thermal transmittance is reduced by over 70% and the internal surface temperature is increased by 2.2oC significantly reducing the risk of surface condensation reducing the risk of mould and creating an unhealthy indoor environment.

GBE Features & Benefits Schedule

| Thermo-Pro Features: | Thermo-Pro Benefits: |

| Purpose made solutions | Made for retrofit EWI (not designed for new build EWI) |

| Solves the problem of existing external attachments | No need to ignore them or stop insulation short any more |

| Comprehensive set of solutions | Enables a complete competent EWIS |

| Readymade set of complimentary parts | Faster, simpler installations |

| Thermo-Pro Profiles can be fitted by details specialist ahead of the EWI main insulation works | Simplifies and speeds up the job of the primary EWIS specialist sub-contractor. |

| Readymade parts fit and accommodate EWI | Compatible with BBA Certified EWI Systems on market |

| Lightweight and simple installation | Thermo-Pro Profiles can be fitted without scaffolding. |

| ??? | Reduced disruption to access. What does that mean? |

| Robust profiles | Reduce risk of damage to EWI insulation. |

| Superior Weatherproofed solution | Superior and simple compared to made-up on site solutions |

| Pre-finished solution | Painting not dictated by weather conditions on site |

| Lead, plastic or powder coated aluminium | Long life durable materials and finishes |

| Profiles have built-in thermal break insulation | No thermal breaks bridges in EWI. |

| Increased Internal Surface Temperature | Reduces risk of internal surface condensation |

| Warm and dry internal surfaces | Avoids risk of damp activating spores generating mould |

| Mould-free surfaces | Avoids risk of asthma and other respiratory illnesses |

| Mould-free surfaces | Keeps accommodation fit for purpose and occupied |

1 ThermoPro® Thermo-Bead

DESCRIPTION

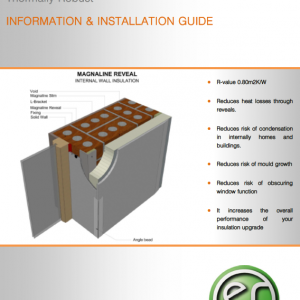

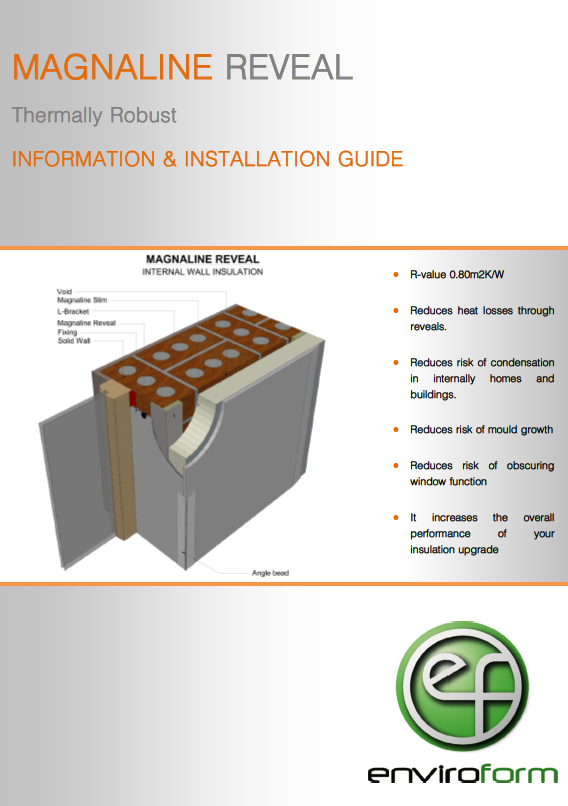

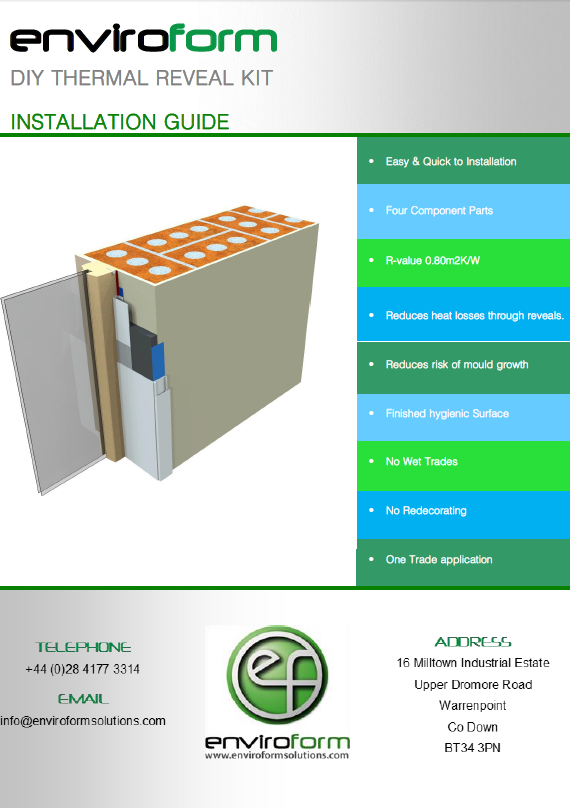

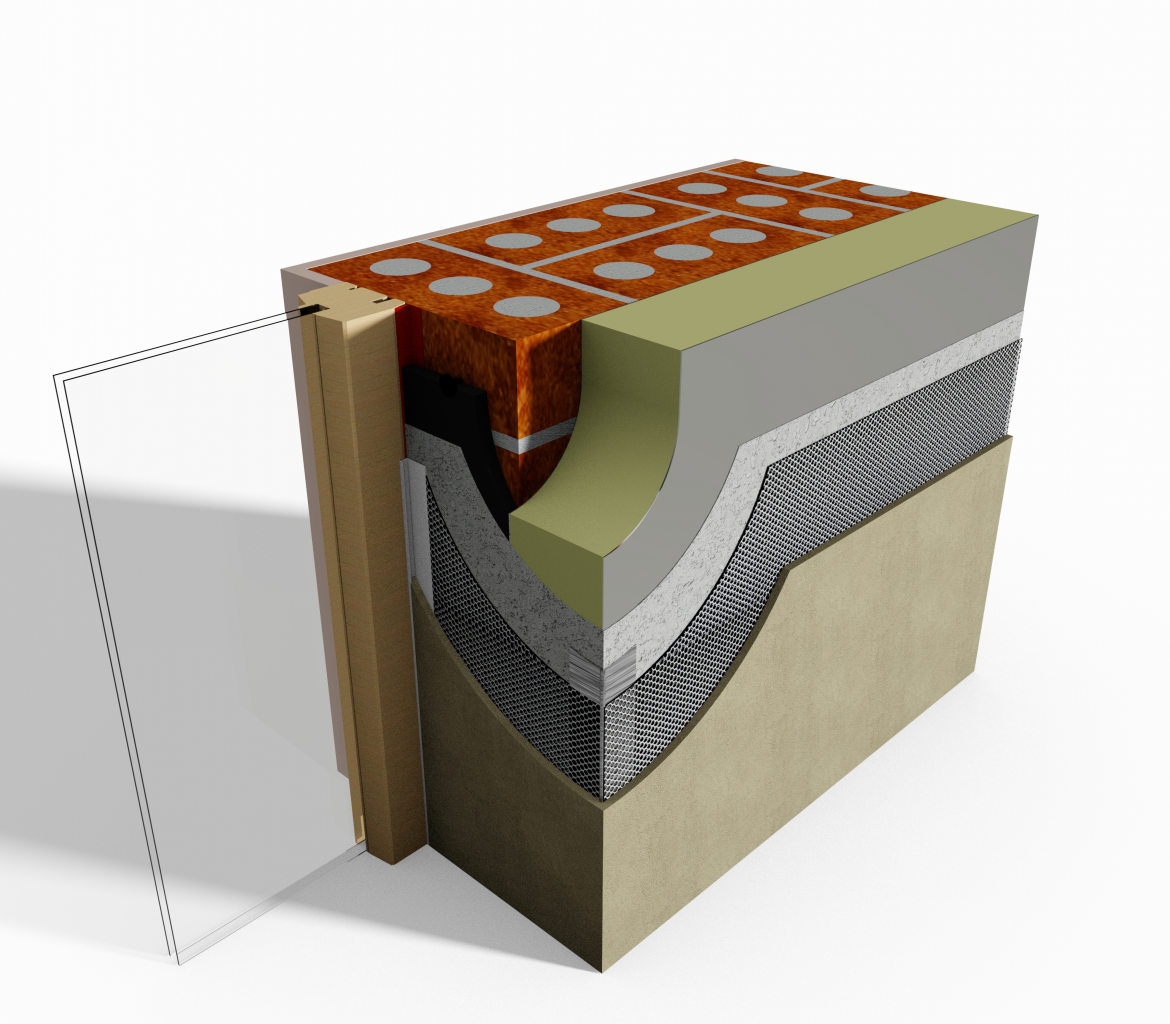

Thermo-Bead is a simple, fast, cost effective and ultra-thin solution to deal with the cold thermal bridging at external window and door reveals.

Thermo-Bead comprises of standard beads insulated with 10mm of Aerogel insulation and integrates seamlessly into all existing EWI systems leaving a finished depth of just 17mm.

- Thermo-Bead 10mm + 7mm Coating = 17mm

- Graphite EPS 23mm + 7mm Coating = 30mm

Space saving: 13 mm

KEY ADVANTAGES

Using Thermo-Pro® Thermo-Bead with 10mm of Aerogel thermal conductivity insulation provides the same thermal resistance as 23mm of Graphite EPS, saving 13mm of valuable space for windows and doors to openings.

GBE Accessories

- Thermo-Pro Thermally insulated profiles for EWI (External wall insulation)

- 1 G#8714 Thermo-Bead (this page)

- (Window/Door Reveal Lining for EWI)

- 1 G#8714 Thermo-Bead (this page)

-

- 2 Thermo-Pro Soil Pipe

- (behind vertical and sloping pipes & other abutments in EWI)

- 3 Thermo-Pro Fascia

- (EWI abutments at eaves with little or no overhang)

- 4 Thermo-Pro Finlock

- (Precast concrete gutter Fascia

- 5 Thermo-Pro Eaves/Gutter

- (abutments for EWI)

- 6 Thermo-Flash (Gutter Fascia)

- 7 Thermo-Flash

- (Lead Flashing for EWI to pitched roof)

- 8 Thermo-Trac

- (Below DPC EWI skirting with RWP cutout)

- 9 Thermo-Trac Dynamic

- 10 Thermo-Pro Column Cladding Insulation

- 2 Thermo-Pro Soil Pipe

- External Floor/Walkway and roof terrace/balcony insulation systems

- Underside:

- Floor Soffit Cable trunking Insulation

-

- Thermo-Pro Thermally insulated profiles for IWI

- Underside:

- Thermo-Pro Thermally insulated profiles/Accessories for IWI (Internal Wall Insulated lining)

- 8 Thermo-Soc

- (Thermal break for electrical socket in IWI)

- 9 Magna-Reveal (Jamb lining for IWI)

- 10 DIY Thermal Reveal/Return Kit

- 11 Thermo-Joist

- 8 Thermo-Soc

- Solid Wall Masonry Accessories

- Sil-T Vapour permeable biocide sealer for masonry

- SIL-T20 Vapour permeable Impregnating Adhesive

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

GBE Incubator

Draft Statement

INTRODUCTION

Cold Thermal Bridging in External Wall Insulation (EWI)

Enviroform Solutions Ltd. have developed a number of unique products using Aerogel thermal conductivity insulation combined with various materials, to tackle the issue of cold thermal bridging and weathering at key junctions when installing External Wall Insulation.

The Key Junctions in question addressed are:

- 1 Windows & Door: Reveals & Sills

- 2 Soil Pipes & Gate Posts / Fences

- 3 Eaves & Gutter: where little or no overhanging soffit exists

- 4 Lead Flashing Details: Bay windows to walls – Single storey beside two storey; EWI above pitched roof

- 5 Below DPMC Level: above ground level

Failure to identify and adequately deal with these cold thermal bridging elements can lead to

- A Increased heat loss from a dwelling compared with what was assumed determined during energy modelling.

- B The Risk of surface condensation or mould from lowered internal Surface temperature at or near the Thermal Bridge Junction.

- C Risk of mould growth from spores in surface condensation at or near the Thermal Bridge Junction.

By introducing the Thermo-Pro® Soil Pipe insulated profile the linear thermal transmittance is reduced by over 70% and the internal surface temperature is increased by 2.2oC significantly reducing the risk of surface condensation reducing the risk of mould and creating an unhealthy indoor environment.

GBE Features & Benefits Schedule

| Thermo-Pro Features: | Thermo-Pro Benefits: |

| Purpose made solutions | Made for retrofit EWI (not designed for new build EWI) |

| Solves the problem of existing external attachments | No need to ignore them or stop insulation short any more |

| Comprehensive set of solutions | Enables a complete competent EWIS |

| Readymade set of complimentary parts | Faster, simpler installations |

| Thermo-Pro Profiles can be fitted by details specialist ahead of the EWI main insulation works | Simplifies and speeds up the job of the primary EWIS specialist sub-contractor. |

| Readymade parts fit and accommodate EWI | Compatible with BBA Certified EWI Systems on market |

| Lightweight and simple installation | Thermo-Pro Profiles can be fitted without scaffolding. |

| ??? | Reduced disruption to access. What does that mean? |

| Robust profiles | Reduce risk of damage to EWI insulation. |

| Superior Weatherproofed solution | Superior and simple compared to made-up on site solutions |

| Pre-finished solution | Painting not dictated by weather conditions on site |

| Lead, plastic or powder coated aluminium | Long life durable materials and finishes |

| Profiles have built-in thermal break insulation | No thermal breaks bridges in EWI. |

| Increased Internal Surface Temperature | Reduces risk of internal surface condensation |

| Warm and dry internal surfaces | Avoids risk of damp activating spores generating mould |

| Mould-free surfaces | Avoids risk of asthma and other respiratory illnesses |

| Mould-free surfaces | Keeps accommodation fit for purpose and occupied |

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

- PASS Schedule

- Product

- Accessory

- System

- Screening

- G#515 N#533 GBE PASS

- G#747 N#769 GBE PASS Navigation

GBE Jargon Buster

- G#1057 N#1074 GBE PASS Products Accessory System Screening

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

GBE Library

Enviroform Solutions Ltd.

External Wall Insulation (EWI) Accessories

GBE LCA & EPD

Sub-system Component

- Brochure (See Manufacturer page)

- Promotional Literature

- Technical Literature

- Specification

- Method Statement

- Schedule

- Colour Swatch

- CPD Seminar

- CAD Files

- BBA Certificate

- ETA Certificate

- CE Mark Certificate

- Green Label

- Health Label

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

GBE Accessory Product Data Sheet

Pending

- G#543 N#563 GBE Product Data Sheet

- GBE Accessory Data Sheet

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

BIM CAD Model

- Product Object

- Accessory Object

- System Assembly

- Elemental Assembly

- BIM Products Data Sheet (This page tab 9)

- Digital Object Identifiers (DOI)

- G#452 N#458 GBE BIM

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

BIM Product Data Sheet

Selected from CIBSE BIM Product Data Sheets or developed to suit

- GBE BIM Accessory Data Sheet

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015 – 5th January 2016

Thermo-Pro Thermo-Bead

COBie Spreadsheet

- COBie Excel Spreadsheet

- GBE Excel Short Spreadsheet

- Short code URL

- GBE Repository for LCA data for Environmental Cell

- GBE 301 Redirect file to maintain links

- GBE BIM COBie Data Sheet

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

Draft Specification Clause: Accessory

M21 INSULATION WITH RENDERED FINISH (EXTERNAL WALL INSULATION EWI)

To be read with the Preliminaries/General conditions[ A10-A55 and A90]

260E THERMAL BREAK TO WINDOW/DOOR OPENING JAMBS WITHIN EWI

- Drawing Reference(s): [________]

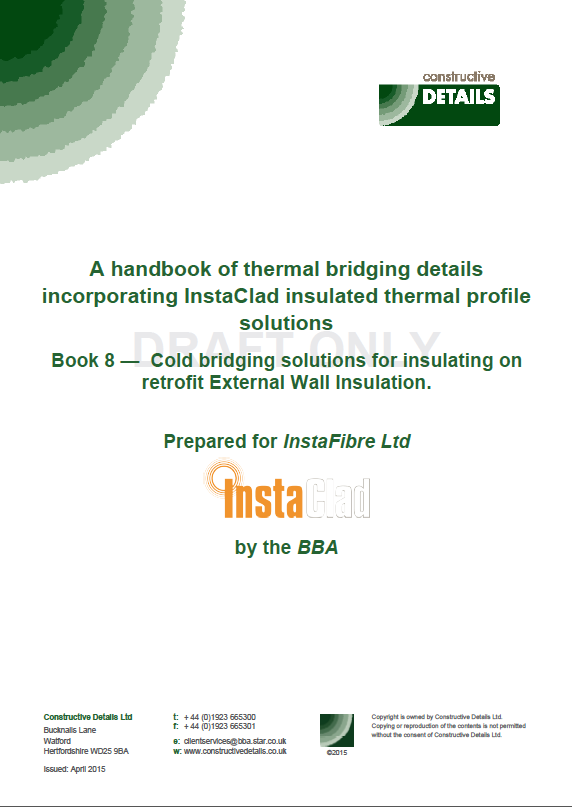

- Constructive Details Ltd.:

- CD0107 Thermo-Bead

- Reference Documents:

- Constructive Details Ltd.:

- A handbook of thermal bridging details incorporating Instaclad insulated themal profile solutions

- Book 8 — Cold bridging solutions for insulating on retrofit External Wall Insulation

- Substrate: Existing 1 Brick thick solid brick/masonry wall; fair faced externally; plastered internally.

- Existing window or door in position against masonry opening jamb.

- Opening Jamb Insulation Bead: Thermal conductivity insulation to jamb, from outer face of window/door to outer face of masonry.

- Thermal Conductivity Insulation:

- Insulation Material: Aerogel

- Product Reference: Spaceloft Aerogel

- Manufacturer: Aspen Aerogels Inc. USA

- Thickness: [5/10] mm

- Protection: Vapour Control Layer: Foil wrapped Insulation

- Product Reference: Thermo-Pro Thermo-Bead

- Model Reference & Size: [

- TB5/1: 5 x 50 x (cut from) 2500 mm.

- TB5/2: 5 x 75 x (cut from) 2500 mm.

- TB5/3: 5 x 100 x (cut from) 2500 mm.

- TB5/4: 5 x 125 x (cut from) 2500 mm.

- TB5/5: 5 x 150 x (cut from) 2500 mm.

- TB10/7: 10 x 50 x (cut from) 2500 mm.

- TB10/8: 10 x 75 x (cut from) 2500 mm.

- TB10/9: 10 x 100 x (cut from) 2500 mm.

- TB10/10: 10 x 125 x (cut from) 2500 mm.

- TB10/11: 10 x 150 x (cut from) 2500 mm.]

- Profile: pressed/extruded angle

- Metal: Aluminium

- Finish: Powder coated to work section Z31

- Colour: not exposed, no colour requrements,

- Colour: [______], RAL/BS 4800: [________].

- Gloss level: [________] %

- Installation: See M21/390E

- Fasteners: assuming brickwork and lime mortar

- Material: [________]

- Type: [________]

- Size: [________]

- Spacing: [________]

- Apply insulation across opening jamb, against both masonry and fixed window/door frame, with angle bead outwards from opening jamb in contact with outer-face of fixed frame of window/door, to receive render system.

- © GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 5th January 2016

Thermo-Pro® Thermo-Bead

Application Data Sheet

- GBE Application Data Sheet

- (Based on CAPEM Product Data Collection Sheet)

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

GBE Products

See Tab 2 About Acccessory & 14 Systems

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

GBE Sub-systems

- IWI internal wall insulation by others

- Thermo-Soc Accessory by Enviroform Solutions Ltd.

- IWI internal wall insulation by Enviroform Solutions Ltd.

- E-line Superslim

- E-Line Slim

- E-line Natural

- E-Line Natural-Hybrid

- EWI External Wall Insulation System by others

- Accessories by Enviroform Solutions Ltd.

- EWI External Wall Insulation System by Enviroform Solutions Ltd.

- External Wall & Walkway/Balcony/Roof Parapet Sides:

- Renderline Superslim

- External Wall & Walkway/Balcony/Roof Parapet Sides:

- Square hollow steel columns by others

- Insulating cladding by Enviroform Solutions Ltd.

- Ultratherm Aerogel Flooring for retrofit

- E-Therm Slim Floor

- (Insulated Dry Floor System)

- E-Therm Slim Floor

- External Floor/Walkway and roof terrace/balcony insulation systems

- Topside:

- Instaline Superslim Balcony Insulation Solution

- CTF (Cut to Fall) Superslim Balcony/Terrace Insulation Solution

- Cut to fall Balcony Insulation

- Parapet Side:

- Renderline Superslim

- Underside:

- E-Line (all 4 systems?)

- Underside Accessories:

- Floor Soffit Cable/Pipe tray Insulation

- Topside:

- Pitched Roof Insulation

- Within Batten Zone

- Products

- Accessories

- Elemental Assemblies

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- SYSTEM SPECIFICATION CLAUSE TITLE

- Reference Drawing(s): [_______] (left blank for project editor)

- Location: [_______] (left blank for project editor)

- System Assembly:

- Product(s): to [____/____]

- Accessories: to [____/____]

- Elemental Assembly: [________]

- Legend Reference Number: [________]

- Substrate: [_______] (left blank for project editor)

- Preparation: [_______] (left blank for project editor)

- Application: [________]

- Specification

- Schedule

- Method Statement:

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

Elemental Assemblies

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- ELEMENTAL ASSEMBLY CLAUSE TITLE:

- Legend Element Reference: [________]

- GBE BEACON: [________]

- Reference Drawing(s): [_______] (left blank for project editor)

- Location: [_______] (left blank for project editor)

- Schedules: [________]

- Elemental Performances: to [________]

- Prior Element: [_______] (left blank for project editor)

- Prior trade sign off: [________]

- Substrate: [_______] (left blank for project editor)

- Preparation: [_______] (left blank for project editor)

- Components: (bottom to top; outer, core to inner)

- Sub Assembly System: Below: [________] to [____/____]

- Core Assembly System: Horizontal: [________] to [____/____]

- Sub Assembly System: Above: [________] to [____/____]

- Sub Assembly: Outer: [________] to [____/____]

- Core Assembly System: Vertical: [________] to [____/____]

- Core Assembly System: Pitched: [________] to [____/____]

- Sub Assembly: Inner: [________] to [____/____]

- Testing: [________]

- Following trade sign off: [________]

- Protection: [________]

- Protection: maintenance/checking: [________]

- Protection Removal: [________].

- Cleaning: [__________].

- Other requirements: [________].

GBE Collaborate Services

- G#1226 N#1227 GBE Elemental Assemblies

GBE Jargon Buster

- N#1618: B03 Elemental System Performance

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

Elemental Sub-Assembly Specification

Insulated Thermal Break Edge Profiles for EWI

Draft Specification clauses

M21 INSULATION WITH RENDERED FINISH (EXTERNAL WALL INSULATION EWI)

To be read with the Preliminaries/General conditions[ A10-A55 and A90]

210E EXTERNAL WALL INSULATION SYSTEM (EWIS)

- Drawing Reference(s): [________]

- Performance:

- U value: [________] W/m2.K

- No thermal bridges at abutments, openings, services.

- Structural background/Substrate: [Masonry/Brickwork]

- Preparation: [

- Remove and reclaim to refit rainwater gutters and down pipes

- Remove and reclaim to recycle lead flashings]

- Pretreatment: Fungicidal wash if recommended by system manufacturer.

- Insulated thermal break edge profiles to M21/260E

- EWIS:

- Manufacturer: [________]

- Product Reference: [________]

- BBA Agrément Certificate No.: [____/____]

- Insulation material: [________]

- Thickness: [________] mm.

- Density: [________] kg/m³.

- Minimum compressive strength: [________] kN/m².

- Method of fixing: [________]

- Render Base coat: [________]

- Render carrier/Reinforcement mesh: [________]

- Method of fixing: [________]

- Corner reinforcement beads: [________]

- Abutment stop beads: [________]

- Render: [________]

- Decorative finish: [________]

260E INSULATED THERMAL BREAK EDGE PROFILES FOR EWI

- Drawing Reference(s): [________]

- Constructive Details Ltd.:

- CD0058 Thermo-Pro Soil Pipe

- CD0107 Thermo-Bead

- CD0108 Thermo-Trac

- CD0109 Thermo-Pro Fascia

- Reference Documents:

- Constructive Details Ltd.:

- A handbook of thermal bridging details incorporating Instaclad insulated thermal profile solutions

- Book 6 — Thermo-Pro Soil Pipe solution for insulating on retrofit External Wall Insulation

- Book 8 — Cold bridging solutions for insulating on retrofit External Wall Insulation

- External wall insulation system: See M21/210E

- System Reference: Thermo-Pro®

- Accessory References: [

- 1 THERMO-BEAD See M21/265E

- 2 THERMO-PRO SOIL PIPE See M21/270E

- 3 THERMO-PRO FASCIA See M21/275E

- 4a THERMO-FLASH LEAD See M21/280E

- 4b THERMO-FLASH ALUMINIUM See M21/281E

- 5a THERMO-TRAC See M21/285E

- 5b THERMO-TRAC DYNAMIC See M21/286E

- 6 THERMO-PRO GUTTER BOX M21/276E]

- Manufacturer: Enviroform Solutions Ltd. Unit 16, Milltown Industrial Estate, Upper Dromore Road, Warrenpoint, Co. Down, BT34 3PN, Ireland.

- T 028 4177 3314 M 07730 766038

- E liam@enviroformsolutions.com W http://www.enviroformsolutions.com

- Contact: Liam Brown, Managing Director

- Supplier: Enviroform Solutions Ltd.

- Installer: [Main Contractor/EWIS Contractor/Sub-contractor/Trade Contractor]

- Checking and verification of installation: Use the Guidance Checklist in the Constructive Details handbooks [6 & 8]

- Provide 2 copies of the completed checklist, signed by the installer’s Director, to the CA upon completion.

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

Workmanship Specification Clause

Draft Specification

M21 INSULATION WITH RENDERED FINISH (EXTERNAL WALL INSULATION EWI)

To be read with the Preliminaries/General conditions[ A10-A55 and A90]

390E INSTALL THERMAL BREAK TO WINDOW/DOOR OPENING JAMBS WITHIN EWI

- See M21/260E.

- Installation: Apply insulation across opening jamb, against both masonry and fixed window/door frame, with angle bead outwards from opening jamb in contact with outer-face of fixed frame of window/door, to receive render system.

- External Wall Insulation (EWI) to outer face of brickwork and overlapping full thickness of jamb bead Insulation

- External Render:

- Overall thickness: 7 mm

- Base coat: Applied to: outer face of EWI, Jamb face of EWI and exposed face of Aerogel to abut fixed window/door frame outer face.

- Apply reinforcement mesh to basecoat and corner reinforcement.

- Apply internal corner stop bead to mesh at junction with fixed window/door frame

- Apply render top-coat to mesh and window/door stop bead.

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

Waste Specification

- CAWS/NBS/GBE Building Work section: A38

- NBS/NGS/GBE clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- WASTE CLAUSE TITLE:

- %%%pending

- Packaging and Protection requirements

- Recycling Opportunities

- Reuse Opportunities

- European Waste Catalogue reference

- Waste Category

- Waste Recycling and Reuse Appendix

- GBE GBS Waste Specification

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 5th January 2016

Thermo-Pro® Thermo-Bead

FM Spec In Use Maintenance Specification

- CPD Seminar

- Schedule

- Method Statement

- Specification

- Availability

- Spares

- Maintenance

- Frequency

- Materials

- Tools

- COBie Data

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- MAINTENANCE CLAUSE:

- %%%pending

- GBE GBS FMSpec Specification clause

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

End Of life Options

- Pre Alteration Audit

- Pre Demolition Audit

- Soft Strip

- Resale Opportunities

- Reuse Applications

- Reuse Accreditation

- Deconstruction

- Accessory Passport

- Demolitions

- Waste Category

- European Waste Catalogue reference

- Recycling Opportunities

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- END OF LIFE CLAUSE:

- %%%pending

- N#1677 GBE End of life

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

Product/Accessory Passport

- Product Passport

- Accessory Passport

- Provenance

- Pre Alteration Audit

- Pre Demolition Audit

- Original Building

- Exposure Condition

- Orientation

- State of repair

- Quantity

- Properties

- Evidence of Properties

- Deconstruction

- Demolitions

- Palleting Packaging and Protection

- Bar Code/QR Codes

- Information Repositry

- Resale Opportunities

- Reuse Applications

- Reuse Accreditation

- G#1098 N#1116 GBE Product Passport

- GBE Accessory Passport

GBE Jargon Buster

- N#1115: Product Passport

- GBE Accessory Passport

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

See Also:

GBE Jargon Buster

G#1333 N#1320 GBE Jargon Buster Themes

- Refurbishment

Jargon Buster Words and Phrases

- Refurbishment

GBE Checklist

- G#606 N#627 GBE New Build Checklist Navigation

- M21 Insulation with Rendered Finish

- G#730 N#752: GBE EBC Checklist Refurbishment

- M21 Insulation with Rendered Finish

- G#1253 N#1252: GBE EBC Checklist Refurbishment Decent Homes

- G#1438 N#1408 GBE Home Improvement Index

GBE Code

GBE Q&A

GBE Defects

- External Wall Insulation: Insulation with Rendered Finish

- GreenDeal & ECO failings

GBE CPD

Theme

- G#1451 N#1419 GBE CPD Refurbishment and Retrofit

- N#601: Refurbishment

GBE Lectures

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

GBE Echo

- Manufacturer’s Environmental Self-Declaration to ISO 14021

- Independent Validation of Manufacturer’s claim to ISO 14021

- Report

- Evidence Documents

- Factory Visits

- Public Disclosure Document Schedule

- URL to Repository for Public Disclosure Documents

- 301 Redirects to maintain links

%%%Pending

- GBE Echo

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

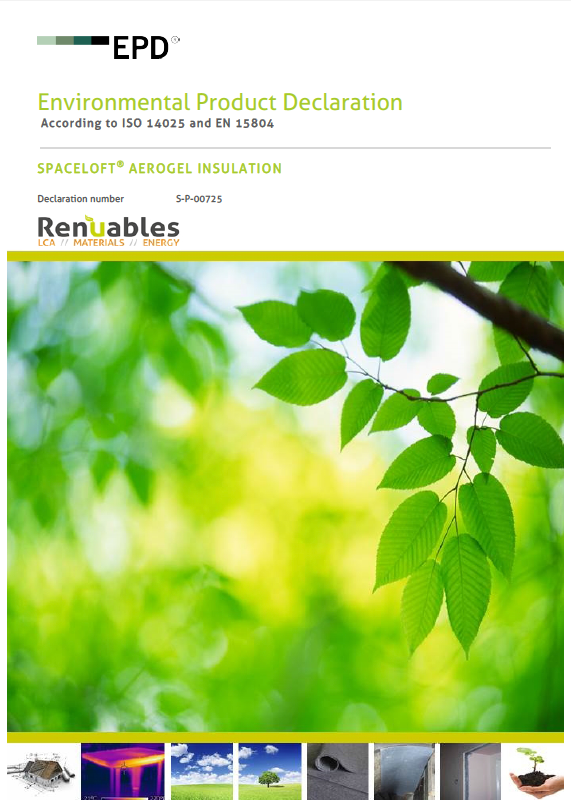

LCA Life Cycle Assessment

EPD Environmental Product Declaration

This EPD is for the Aerogel insulation only

It was carried out Renuables (UK Consultant and later Sub-Partner of CAPEM LCA & EPD project)

Spaceloft EPD PDF

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

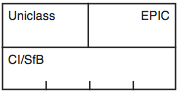

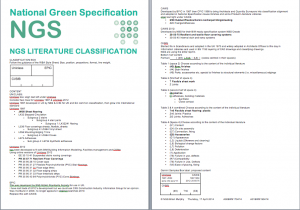

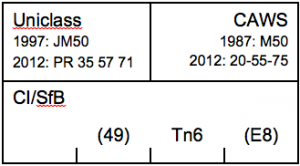

GBE Classify

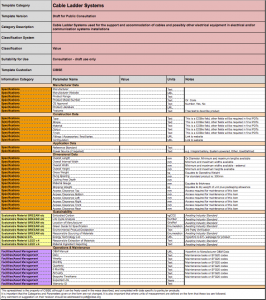

CAWS 1987:

- M21 Insulation with Rendered Finish

CAWS Elemental 2012:

- _

CI/SfB 1976:

- (21.9) Walls, External Walls

- (21.9) Accessories

- (41) Wall Finishes External

- R Rigid Sheet Work

- P Thick Coating Work

- Z Joints

- h Metals

- m inorganic fibres

- n Plastics

- t fixing and jointing materials

Uniclass 1997:

- J M21 Insulation with Rendered Finish

Uniclass Elemental 2012:

- _

Uniclass for BIM 2015:

- _

GBE Collaborative Service

G#1479 N#1440 GBE Classify

N#1441: 17/04/2014: GBE CLASSIFY:

Service to classify literature developed to Samples Box labelling

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

GBE Manufacturer

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

GBE Supplier

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

GBE Installers/Applicators

COMPANY NAME: Many

- Any EWI Manufacturer Approved Installer/Applicator

- No specialist needed

- Suitable for DIY Do It Yourself (bespoke product for DIY)

- Suitable for BIY Build it Yourself (Self-Build)

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

GBE Swatch

Plastic angle:

- Thermo-Bead

- Colour Options: not visible in finished works

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

18th December 2015 – 9th January 2016

Thermo-Pro® Thermo-Bead

GBE Links

A handbook of thermal bridging details incorporating …

www.constructivedetails.co.uk/wp…/2015/…/CDL-Book-8-Final-Final.pd…

Thermo-Trac. 6. E5. CD0109. Thermo-Pro Fascia. 8. E10. The details have been prepared taking into consideration a range of wall constructions used in the UK …

[PDF] EWI Cold Bridging & Weathering Product Brochure

www.enviroformsolutions.com/…/EWI-Cold-Bridging-Weathering-Prod…

Thermo-Pro-Soil Pipe. 3. Thermo-Pro-Eaves/Gutter. 4. Thermo-Flash. 5. Thermo- Trac. Failure to identify and adequately deal with these cold bridging elements …

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

6th January 2016 – 9th January 2016

18th December 2015 – 9th January 2016