Overheating Issue Paper

GBE > Encyclopaedia > Code > Issue Paper > Overheating > G#145

GBE > Encyclopaedia > Code > Issue Paper > Overheating > G#145

Overheating before and after energy saving retrofit or future-facing adaptations

Many specialists in the UK have explored overheating in summer but none appear to have found the primary problem and not found the whole solution. Most of the proposals just fine tune the problem but do not solve it. Zero Carbon Hub and NHBC publications are missing the point too. DECC got close with the problem, but not the solution.

Just like the severe and continuous drip feed of storms on the West-country coast 2013-2014 leading to the battering of the coastal towns, closing of a railway line, flooding of the Somerset Levels, Severn estuary and eventually the Thames valley; the nub of the problem was not the congested rivers and drainage dykes, it was the 2 months of prolonged, heavy and incessant rainfall.

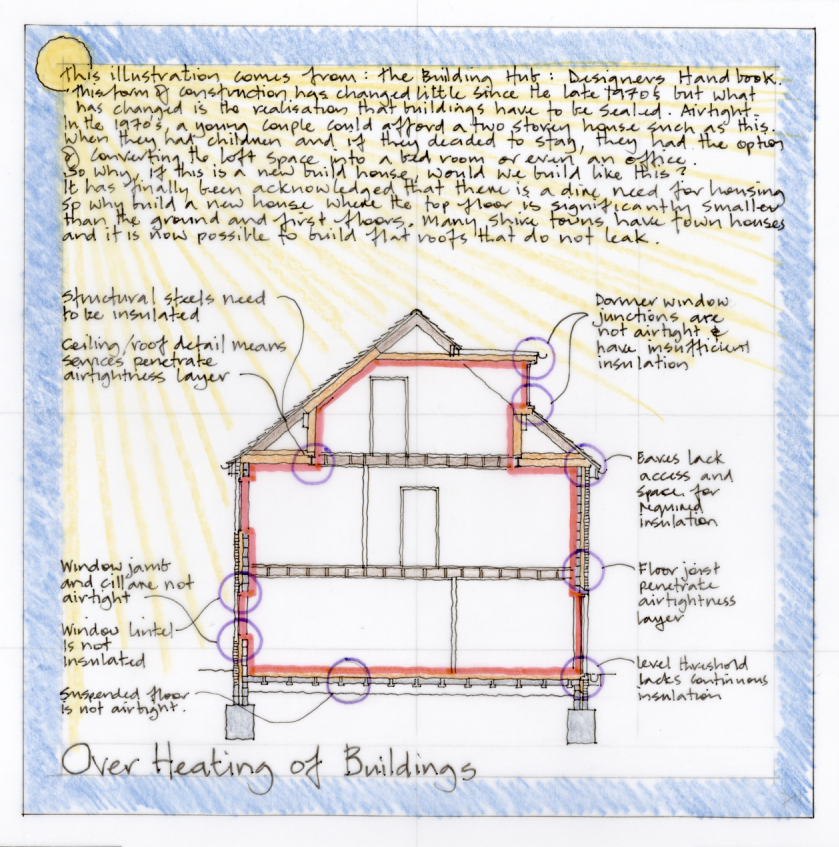

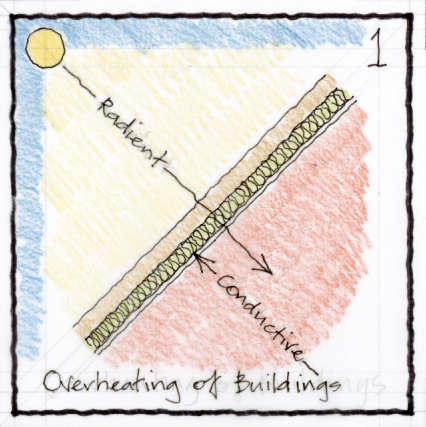

Summer overheating is down to the incessant sun heating of the buildings through the transparent surfaces, but more importantly through the opaque surfaces, roof and walls of lightweight construction.

This is exacerbated by the use of the familiar, cheap, but unfit-for-purpose, wrong thermal insulation materials that permits radiant heat to get in and then prevents conducted heat getting out. (Another greenhouse effect)

We used to teach about this issue in University in the 1970’s but the appropriate and competent materials were not available in the UK market place, so we could not engage with it;

In mainland Europe well away from the mild Atlantic weather, in more intensely urbanised settlements, more prevalence for summer overheating will have prompted action, the problem has been understood and they have developed the products to address it for over 30 years.

Today those right materials are in the UK market. The Greens have been bringing these products into the UK for 15-20 years and promoting their use.

However the UK market obsessed with fiduciary rules and making a profit; mainstream construction is not interested in investment, or in climate change, unless regulated or customer driven.

Customers do not understand overheating either, so the problem remains unresolved and the solution remains a green fringe benefit.

Stop the heat getting in and the other proposed solutions by ZCH and NHBC can work more successfully.

There are many other problems and solutions to be addressed.

Overheating in winter is often communal and district heating flow and return pipes inadequately insulated, under-floor heating in confined communal spaces; added to by cavity party walls acting as chimneys moving heat to other parts of buildings.

Passivhaus or EnerPHit designed housing and better specification, commissioning and optimisation of any residual insulated communal services could fix these.

Green Building Encyclopaedia (GBE) has a GBE Issue Paper on Overheating that goes into great detail on all the contributing factors. Its is currently 81 pages, on its 11 update, 235 topics, including:

Start here to see all the pages so far related to Overheating.

https://greenbuildingencyclopaedia.uk/?p=2613

Straight to the Overheating Paper

https://greenbuildingencyclopaedia.uk/?p=145

I have just skimmed through all the ZCH publications about overheating and have not found any evidence that they know the big problem let alone the big answer.

They have lots of clues about the obvious and smaller problems, but not the big one.

If their ambitions for Energy Experts are carried out with conventional know-how we will race faster into oblivion.

Quoting from: Overheating in Homes Drivers for Change

“In recent decades there has been a strong drive towards reducing heat loss in homes and winter heating costs by incorporating energy efficiency measures.

As a result, new-build dwellings are highly insulated and airtight and lose much less energy through the building fabric.

Millions of existing buildings have also been retrofitted with insulation and other energy efficiency measures.

Such measures are extremely beneficial in winter – helping to keep homes warm and to save energy – but could have unforeseen and unintended consequences in summer if not managed.

For example, insulation keeps homes warm in winter and helps keep them cooler in summer, but effects such as solar gain can cause an increase in internal temperatures which are potentially difficult to dissipate”.

GBE Comment:

“Unforeseen and unintended consequences”:

Solar heating through opaque fabric has been understood since the 1970s and taught at university and long forgotten by many, but not understood by Building Regulations and compliance design tools.

Unintended or not the Regulations focussed on conductivity and ignoring solar radiation resistance are causing overheating.

“If not managed”:

You cannot manage solar heat gains through opaque fabric very easily they are of such magnitude; opening windows, ventilation or shading at windows will not manage it.

“insulation…helps keep them cooler in summer”:

Wrong, the vast majority of insulation used in UK pitched or flat roofs will not help keep buildings cooler in summer.

They are the wrong materials with the wrong properties.

They will let the solar radiant heat in and prevent that heat getting out by conduction.

They are more likely to keep them hotter in summer.

“effects such as solar gains”:

Assuming they are referring to solar gains through glazed parts.

“Potentially difficult to dissipate”:

Ventilation will help remove ‘glazed part solar heat gains’ relatively easily, but added to ‘opaque part solar heat gains’ there is a lot less hope of success with ventilation until after the sun has set.

World FM reported on SOM Architect’s Post Occupancy Evaluation (POE) survey report, May 2015, including a recent survey of building occupants in many building use types.

The striking issue was that whilst almost all issues scored fairly well:

See Also:

SOM Post Occupancy Evaluation (POE) survey report, May 2015

You probably think you know what follows and you could leap frog it.

But beware there are quite a few bits you probably don’t know or haven’t joined up before.

They are essential to understand the later bits.

Before we talk about the after effects of energy saving retrofit measure let’s look at buildings in their raw state.

Overheating in summer:

Passive ventilated offices connecting onto atrium that should help cool them but fail

Overheat in winter:

Overheating all year round (including sunny days in winter)

So it’s worth understanding what that is all about before we start thinking about the after effects of adding insulation.

Sun light, Sun-lit building, Sunspaces, Sun-lit surroundings, People/Pets, Services for Living, Consequences

Northern hemisphere

Daytime:

Daylight:

North light:

Overcast sky:

Sunlight:

Moonlight:

Night-time:

Moonlight:

Cloudy or overcast sky:

Clear sky:

Sun’s Solar Heat: drives the wind, its direction, heating or cooling effect of land and ocean masses and weather

Moon: drives the tides and the potential for cooling effect of ocean breezes

Sun and moon: dictate the normal and peak tides

There are at least three aspects to orientation:

‘All buildings face the sun’.

At some point during the day most buildings face the sun.

This is true of detached buildings but this is not always true of:

In some of these cases some properties will not see the sun ever and others will not escape it.

Exposed opaque (solid) parts either permit or prevent solar light/heat gains depending upon their materials and methods of construction.

See Also:

GBE Checklist

GBE Jargon Buster

GBE CPD: Sustaining Towers

GBE CPD: Integer Tower Refurbishment

GBE CPD: Survey Test Analysis

GBE CPD: Refurbishment: Survey Test Analysis

GBE CPD: Zero Carbon Buildings

GBE Case Study: Architectural Competition: Isle of Dogs Mudchute site, Competition Brief Failure

We are encouraged to:

Exposed transparent (glazed) parts permit daylight and solar light/heat gains when they face in the right direction(s).

See Also:

GBE Checklist

GBE Jargon Buster

GBE CPD: L10 Windows

GBE Products: L10 Windows, Rooflights, Roof windows, L20 Glazed Doors

GBE Robust Specification

By others:

Passivhaus Webinar: Passive House Windows for Mediterranean Climates https://youtu.be/YHg4Pt1M5Tw via @YouTube via twitter @JMenendez

Depending upon the geometry of roofs, orientation of predominant ridges and larger slopes is important.

Roof plains include dormers, roof lights, roof windows and can also include solar panels.

Their orientation will determine the quality and amount of light entering the upper floor or attic through glazed parts.

Exposed opaque pitched roofs either permit or prevent solar light/heat gains depending upon their materials and methods.

Exposed transparent parts permit daylight, sunlight and solar light/heat gains depending upon the direction they face.

See Also:

GBE Checklist

GBE Jargon Buster

GBE CPD: Pitched Roofs

Pitched roofs are normally and most often mid to dark tone absorbing the sun and its heat, contributing to overheating of the attic space, room in roof, bedrooms or top floor flat below.

Pitched roofs tile and slates are:

Thatch roof will start lighter yellow and end up mid tone grey and offers some solar radiation resistant thermal insulation.

Exceptionally roof tiles were glazed reflecting some of the sun’s heat and re-radiate the rest inwards.

Malleable metal claddings include:

Exceptionally: (highly reflective; potential glare, migraine or accidents)

Coated profiled metal cladding can be any colour you like from the manufacturers swatch:

Coated flat metal cladding can be any colour you like from the manufacturer’s swatch

Choosing white, lighter colours, lighter tone and low saturation colours potentially:

See Also:

GBE Lectures: Elements: (27.2) Pitched Roofs

Case Study: Self cooling roof: http://www.fastcoexist.com/3047090/with-this-self-cooling-roof-you-might-not-need-a-c?utmcontent=buffer8bbb4&utmmedium=social&utmsource=twitter.com&utmcampaign=buffer

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

Twitter had a tweet about glass roof tiles available from Sweden asking “What would you do with all that free heat?”

You need expensive kit to exploit it, capture it, store it, move it, use it.

A few years back at a TGR event a ST panel inventor presented a glass slate replacement

And what about the embodied energy and carbon of making glass tiles or slate replacements?

Historically a glass or transparent roof tile would replace a tile or two

So what would you do with all that glass roof tiling and no underlays?

So it’s just another stupid idea then.

I realise that the manufacturer has gone to great lengths to produce the tiles and want to sell a few

What do they say any news coverage, good or bad, is good marketing.

Most pitched and mansard roofs will be made of:

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

It is commonplace (seen most times on Grand Design) for timber framed pitched roofs with sloping ceilings to be insulated with foamed plastic insulation for its thinness and high thermal conductivity insulation performance.

Foamed plastics:

Mineral wool:

Cellular glass:

Plant based fibre or flake:

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

At the eaves edges of pitched roofs the roof timber framing tapers to a triangle with say 100 mm vertical end at the supporting wall outer edge.

With UK Building Regulations requiring 200-300 mm of insulation it means the ceiling level conductivity thermal insulation will taper and reduce in thickness at the eaves edges of roofs.

Roof usually also need a 50 mm ventilation gap between eaves and attic, this may be achieved with an airtight wood based panel maintaining the air gap, so the insulation will be reduced further.

The result is a risk of greater heat loss through the ceiling, along the eaves at the most vulnerable position.

With bathrooms and bedrooms often at the external wall, this runs the risk of condensation and mould.

The solution is for new build pitched roof trusses to be designed with a ‘heel’ or vertical at the eaves, the height of the heel should correspond to the thickness of the conductivity thermal insulation on the ceiling.

If the roof is only insulated with conductivity thermal insulation then the upper floor rooms will overheat.

So the heel height should correspond to the thickness of solar radiation resistant and conductivity thermal insulation.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

Far fewer pitched roofs are constructed with heavyweight construction

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

Developers regularly want to maximise profits on developments and so refurbishments of commercial or industrial buildings to residential or commercial will usually require extra floors added to the roof of the building.

T&C Planners will want the extra floors set back so as not to change the character and appearance of the existing buildings.

Setting it back will complicate the structural support and encourage the designers to introduce lightweight framing, lightweight insulation and lightweight claddings.

The top floors are often sold as the penthouse and sold for the highest prices, but will suffer the greatest overheating and probably get air conditioning fitted.

The Architects made the decision that they wanted a heavyweight brick plinth with heavy solar shading and a set back lightweight glazed and metal roof on aesthetic grounds.

The result is relatively sombre dark lower floors and bright and airy top floor.

The top floor also overheats.

Just like ‘Build Tight, Ventilate Right’ a slogan that engages with building air-tight and purposeful ventilation.

The issues of overheating of lightweight construction could do with a slogan too.

Explanation: If you BUILD it LIGHT weight you must INSULATE it RIGHT to keep it SOLAR-TIGHT

Initially: BUILD LIGHT, INSULATE RIGHT, SOLAR TIGHT

Ultimately: BUILD LIGHT, SOLAR TIGHT

BrianSpecMan aka Brian Murphy 11th August 2015

See also:

GBE Jargon Buster: Build Light, Solar Tight

Shallow roofs are normally and most often mid to dark tone absorbing the sun and its heat, contributing to overheating of the attic space, room in roof, bedrooms or top floor flat below.

Malleable metal roofing include:

Coated profiled metal roof cladding can be any colour you like from the manufacturers swatch:

Choosing white, lighter colours, lighter tone and low saturation colours potentially:

See Also:

GBE Lectures: Elements: (27.1) Flat Roofs

GBE CPD: Materials

With flat roofs there is a surface area for solar light/heat gain.

High parapets can offer some shading to the roof area,

In winter the sun will be at an acute (shallow) angle and parapets provide more shading.

In summer the sun will be at an obtuse (steep) angle and parapets provide less shading.

Flat roof plains can include roof lights, plant (mechanical and electrical equipment).

These roof plains can also include solar panels.

Exposed opaque flat roofs either permit or prevent solar light/heat gains depending upon their materials and methods.

Exposed transparent parts of flat roofs permit solar light/heat gains to the interior.

GBE Lectures: Elements: (27.1) Flat roofs

Flat roofs have traditionally been light coloured to reflect the sun and its heat, contributing to the albedo effect.

The light colouring of flat roofs was made with solar reflective white aggregate chippings on built up roofing.

More recently these have been replaced with lower cost or available solutions:

If the covering is thin or uninsulated then the heat will pass through the covering and into the supporting structure.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: Q24 & Q25 Solar reflective paving

GBE Robust Specification

GBE Lectures: Elements: (27.1) Flat roofs

Some of our earliest flat roofs are waterproofed with asphalt

It was often laid with no solar protection,

But old buildings (pre 1960s) with asphalt roofs probably have little or no thermal insulation below.

Asphalt roofs may be laid on concrete roofs or timber framed roofs.

Asphalt can cope with being hot and will absorb a considerable amount to heat, once it reaches saturation point then the heat passes through to the roof below.

If it is concrete the roof will absorb the heat, if it is timber the heat will pass through to the space below.

Rooms below these roofs will be hot during the day but the hot asphalt will take time to cool off and keep the building warn late into the evening.

If the heat has not dissipated by morning then the rooms below will remain hot and get hotter.

See Also:

GBE Checklist

GBE Jargon Buster

GBE: Lectures: Flat roofs

The Victorian occasionally used flooded flat roofs to keep the space below, cool; the water has the ability to absorb the heat of the sun and by evaporation from the top surface, keeping the water cool and the building cool.

The Victorian steam railways used cast iron segmental water tanks on the roof of the water towers to recharge steam engine’s fuel and water tender, they had the benefit of cooling the space below.

The Austrian Architect Walter Segal who championed self-build construction in the UK invented the Waster Segal Method when designing a building for temporarily decanting his family whilst their house was refurbished.

It used a lightweight timber framed construction with flat roof which had 150 mm. high upstands and no overflows.

The roof could be transformed from lightweight to heavyweight by flooding it with water.

This flooded roof offers:

The water reservoir needs to be topped up by garden hose on hot or warm windy evaporative days.

See Also:

GBE Checklist

GBE Jargon Buster

GBE: Lectures: Flat roofs

GBE: Link: Walter Segal Self-build Trust

The New British Library on Euston Road, London has asphalt roofing laid on dense concrete secondary slabs laid to 1:40 falls on sleeper walls with cellular glass solar radiation resistant thermal insulation laid in a hot bitumen flood coat, directly on top of the concrete slab.

If the asphalt were applied directly on the concrete, the heat would be soaked up into the concrete, allowing the asphalt to cool quickly and set to harden.

Cellular glass acts as both solar radiation resistant thermal insulation and conductivity thermal insulation.

When asphalt is applied over cellular glass the heat from the asphalt tries to transfer into the insulation.

The heat only enters the surface of the insulation and does not penetrate further, holding the heat in the asphalt preventing it from cooling and keeping it liquid.

Hot liquid asphalt on a 1:40 fall runs down the slope and has to be pushed back up hill, often until it cools to the air and starts to set to harden.

See Also:

GBE Checklist

GBE Jargon Buster

GBE: Lectures: Flat roofs

Albedo is the earth’s brightness or tone (lightness-darkness) as seen by the sun.

Snow/ice capped polar-regions are light, sea is dark, land is light to dark; the overall effect was an albedo of 0.39.

Snow and ice capping to solar regions fluctuates seasonally at opposite poles and the albedo fluctuates with it.

Glaciers shrink permanently and have an affect on the Earth’s albedo.

See Also:

GBE Checklist

GBE Jargon Buster

GBE: Lectures: Flat roofs

GBE CPD: JQ37 Living Roof Specification

What are important are pitched roofs that accommodate renewable energy solar panels on the right slopes.

The panes may be between dormers and chimneys, ideally without being overshadowed by them.

Solar panels include:

See Also:

GBE Checklist

GBE Jargon Buster

GBE Lectures: Elements: (27.2) Pitched Roofs

GBE Products:

GBE Robust Specifications

Flat roofs do not provide slopes for integrated panels.

However panels can be fixed on frames to set them at optimum angles to see the sun.

Panels on frames will create shading below the panels

Flat roofs with parapets can create shading nearest to the parapets.

Winter sun angles should be used to determine the distance for placing panels away from the parapet.

Even a panel laid flat on a flat roof will produce renewable energy, but less than the optimum.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Lectures: Elements: (27.1) Flat Roofs

GBE Products: Support systems for T15 ST, V10 PV, and T15 & V10 PVT

GBE Robust Specifications

GBE Lectures: Elements: (27.1) Flat roofs

Warm or cold flat roofs place thermal insulation below the waterproof membrane within the roof construction:

Concrete flat roof decks offer decrement delay.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Lectures: Elements: (27.1) Flat roofs

Warm or cold flat roofs place thermal insulation below the waterproof membrane within the roof construction:

Thermal insulation in timber or metal framed flat roofs needs to offer decrement delay.

Flat roofs should therefore use solar radiation resistant thermal insulation.

The combination of the following will suffer from over heating of rooms below:

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specifications

GBE Lectures: Elements: (27.1) Flat roofs

Inverted roofs place the thermal insulation above the waterproof membrane and below ballast (paving slabs or gravel)

Thermal insulation in inverted roofs need to remain dry whilst immersed in rainwater, so needs to be hydrophobic and frost resistant.

Membranes are now available to try to keep the water off the inverted conductivity thermal insulation.

Expanded or extruded polystyrene are often used in inverted roofs because they are hydrophobic.

Expanded or extruded polystyrene are conductivity thermal insulation, which do not offer solar radiation resistant thermal insulation and decrement delay.

Concrete flat roofs offer solar radiation protection and decrement delay and are not likely to cause overheating below.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Lectures: Elements: (27.1) Flat roofs

Why have manufacturers started making water barrier membranes to apply over the inverted roof insulation?

Infrared thermography surveys of flat inverted roofs to check to see how well inverted roofs are performing.

Inverted roofs place the thermal insulation above the waterproof membrane and below ballast (paving slabs or gravel)

Thermal insulation in inverted roofs need to remain dry whilst immersed in rainwater, so needs to be hydrophobic.

Expanded or extruded polystyrene are most often used in inverted roofs.

Expanded or extruded polystyrene are conductivity thermal insulation, which do not offer solar radiation resistant thermal insulation properties not enabling decrement delay.

Timber-framed or metal-framed flat roofs without further thermal insulation do not offer decrement delay themselves.

The combination of timber-framed or metal-framed flat roofs and inverted flat roofing will suffer from overheating of rooms below.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Lectures: Elements: (27.1) Flat roofs

Just like ‘Build Tight, Ventilate Right’ a slogan that engages with building air-tight and purposeful ventilation.

The issues of overheating of lightweight construction could do with a slogan too.

Explanation: If you BUILD it LIGHT weight you must INSULATE it RIGHT to keep it SOLAR-TIGHT

Initially: BUILD LIGHT, INSULATE RIGHT, SOLAR TIGHT

Ultimately: BUILD LIGHT, SOLAR TIGHT

BrianSpecMan aka Brian Murphy 11th August 2015

Living roofs include intensive, green roofs or extensive, brown roofs.

Living roofs are usually flat but systems are available for shallow and pitched roofs

Living roofs can provide solar protection due to thermal mass:

Living roofs can provide evaporative cooling of water from soil or gravels and from some plant leaves.

Living roofs do not normally provide added thermal insulation (other than in the water reservoir layer); that is provided by the conduction thermal insulation needed by the underlying roof.

New methods of creating living roofs are being researched.

Living roofs can also provide solar shading.

Living roofs can also provide solar reflection to add to the albedo effect.

See Also:

GBE Checklist

GBE Jargon Buster

GBE CPD: JQ37 Living Roof Specification

GBE Lectures: Elements: (27.1) Flat roofs

GBE Lectures: Elements: (27.2) Pitched Roofs

Research underway:

New methods of creating living roofs are being researched now that may provide insulation within the build-up using hygroscopic plant materials benefiting from evaporative cooling.

Living roofs and solar panels are often good bedfellow, mutually supportive.

Solar panels are often mounted on frames setting them at an optimal angle; this allows the panels to have cooler undersides, helping with PV efficiency.

This arrangement creates shaded spaces behind and below the panels, with varying levels of light leakage at the edges and full sun in front of the panels.

Plants grown from seeds dropped with bird poo as fertiliser inhabit brown roofs.

Brown roof plants inhabit spaces behind, between and below panels.

Brown roof plants providing some shade, cooling effect and evaporative cooling to panels.

As long as plants do not overshadow panels they are complimentary.

See Also:

GBE Checklist

GBE Jargon Buster

GBE CPD: JQ37 Living Roof Specification

Panels should ideally all face south but south +or- 30 degrees is okay.

South-westerly is preferred south-easterly since the day warms the longer the sun has been around.

Ideally roof needs to have pitched roof orientation to match.

The roof’s pitch, i.e. angle of roof slope above horizontal, is important, ideally orthogonal (right angle) to the angle of the sun.

Since the angle of the sun varies all year and all day roof pitch is less important.

Even a panel laid flat on a roof will have generate renewable energy, but less than the optimum.

Panel spacing becomes important in solar farms one row must not overshadow the next row in winter.

Solar farms can be ground or roof based.

Tables exist showing percentage of output for different orientation and pitch, compared to optimum

If ST panels are for domestic hot water they need to face the sun all year but are likely to be most effective during summer and less so in winter.

Domestic hot water used at hand wash bowls, sinks and dual supply washing machines is used in non-domestic buildings too.

If ST panels are for space heating they need to face the sun in winter at lower sun angles so they should be placed more vertical.

It’s suggested these be attached to walls not roofs, and are suitable on the lower, steeper slope of mansard roofs.

Some argue there is insufficient heat in winter, but they can contribute beneficial heat as part of a pre-heat strategy.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: T15 ST Solar Thermal panels

GBE Robust Specification

BIRE is argued to be most appropriate, meaning solar panels are incorporated in building construction replacing roof coverings not sitting above them on support frames.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: T15 ST, V10 PV, and T15 & V10 PVT.

GBE Robust Specification

ST panels are likely to be enclosures with heat absorbing panels laying on thermal insulation in a sealed enclosure. ST panels glass should minimises external reflection, maximises sunlight entry, maximises internal reflection, to minimise heat egress, maximising performance.

The right insulation needs to be adopted then conducted and radiated heat from the hot panels should not pass through the bottom of the enclosure.

If the heat stays in the panel it won’t enter attics, rooms in roof or bedrooms below to add to overheating.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: T15 ST,

GBE Robust Specification

PVs are known to diminish performance when hot; they rely upon ventilation below the panel to keep them cooler.

BIPV panels are likely to be a simple panel replacing the roof tiling fixed over the battens and roofing felt.

This results in a tight ventilation labyrinth below the panel within the batten zone and above roofing felt.

Once PV panels are solar heated they will reradiate from their underside through roofing felt or BRM to heat up spaces below.

In order to overcome this heat build up, a number of options exist:

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: V10 PV

GBE Robust Specification

PVs are known to diminish performance when hot; they rely upon ventilation below the panel to keep them cooler.

BIPVT panels incorporate ST panels below PV panels.

Once PV panels are solar light/heated they will reradiate from the underside into the ST panels to heat it up.

The ST panel will take the heat away to:

All of this will potentially offer some overheating protection to the space below the roof.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: T15 & V10 PVT

GBE Robust Specification

If the building, roofs, glazing and panels all face in the right direction to capture solar light/heat this helps to enable solar light/heat gains.

However the presence of land, buildings, trees or tall bushes, if they are high enough into the sun’s path, can block the sun’s rays.

If they are coniferous they are likely to block the sun’s rays in the summer and winter.

However if they are deciduous they shade buildings in summer, their leaves will fall in autumn, allowing ray’s to reach their targets in winter.

Sunlight passing through a tree canopy between breeze-driven fluttering leaves will fall as dappled light, which is regarded as delightful.

Dappled light reduces the amount of solar light/heat gain but can still cause intermittent glare.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Service Providers: Solar Access surveys

Sun’s rays beam down onto buildings hitting roofs, rooflights, roof windows, walls, windows and doors (glazed or not).

The heat of the sun lands on the outer surfaces of the opaque parts of the building or passes through the glazed parts falling on floors and walls of interiors beyond the glass.

What happens next depends upon their method of construction and materials at their external and internals surfaces.

These descriptions often confuse the general public, and it is worth a moment of our time.

I have see “Why would you use a cold roof, why not insulate?” in online forum.

Its not about insulation or not, its about where the insulation is positioned.

A cold, pitched roof will have the insulation at the horizontal ceiling.

Cross ventilation of the roof void will occur above the insulation in the attic space.

In winter with house heating on roof timbers and the attic space are therefore cold whilst the rooms below are warm.

A better description might be a Winter Cold Roof.

A warm, pitched roof will have the insulation at the sloping rafters.

The cross ventilation must occur above this insulation within the batten zone of the covering.

There would be no need for insulation at the ceiling level.

In winter with house heating on the roof timbers, the attic space and the rooms below are therefore warm.

A better description might be a Winter Warm Roof.

I just (04/08/2015) read in an eNewsletter from a fastener manufacturer:

“Traditional cold roof constructions are giving way to their opposite – the warm roof. This method of construction delivers a host of extra benefits and is now commonly believed to be the single best roofing option for the changeable climate of the UK.”

On the face of it that sounds possible, but UK mainstream construction does not understand the different properties of thermal insulation materials, i.e. Conductivity thermal insulation v solar radiation resistant thermal insulation.

So that statement can be wrong if you choose the wrong insulation types.

I just (04/08/2015) read in an eNewsletter from the same fastener manufacturer:

“In a recent article we revealed the many benefits of warm roof constructions and some of the many factors that need to be considered during the complex and delicate process of design and specification.

features and benefits of these superior Warm Roof Batten Fixings include:

They too do not understand the difference between Conductivity thermal insulation and solar radiation resistant thermal insulation.

Using any of the products listed, all conductivity thermal insulation, summer hot roof overheating will occur.

Whilst high decrement delay materials, not listed above, in their place, summer cool roof will occur.

“Environmental Awareness – A building installed with warm roofing will use substantially less energy than before, reducing carbon footprint”

I am not sure how they come to this conclusion, but:

“100% glazed facades without solar shading is like dating-site sex without protection: lots of it, a lot sexier, but bloody irresponsible” based on quote by Robin Nicholson

100% glazed does mean 100% air-conditioned, air conditioning has very high energy and carbon demands, generates heat waste, needs Voltage Optimisation and Legionella health and safety maintenance regimes in place and costs lots of money to run.

Very High OPEX, very High TOTEX

By others:

Passivhaus Webinar: Passive House Windows for Mediterranean Climates https://youtu.be/YHg4Pt1M5Tw via @YouTube via twitter @JMenendez

Letting Agents have begun to dictate architectural style of commercial offices to let, yet again.

On the basis that it’s easy for them to let 100% glazed facades and those who can, want an easy life.

In reality developers want the best net to gross ratio to charge for the largest rentable floor area; profitable low CAPEX

So developers prefer 25 mm glass instead of 300-500 mm of masonry.

It is allegedly desirable by tenants to have 100% glazed unrestricted views.

And in reality every tenant knows they suffer from:

The solutions include:

prisms to reflect sunlight but permit daylight.

tubular insulation that blocks high angled sun but permits low angled sun

Generating heat internally

Make the building look less attractive when they are all set at different heights and angles and if they are distorted or damaged.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

prisms to reflect sunlight but permit daylight.

tubular insulation that blocks high angled sun but permits low angled sun

GBE Robust Specification

Heavyweight wall construction including:

Will soak up heat of the sun’s rays on outer faces of walls, the heat won’t reach the interior of the building and so has little effect upon the internal temperature.

See Also:

GBE Products:

GBE Robust Specification

In a recent HCA conference on Overheating

One speaker consistently used Rejection where I would prefer to hear Removal

He used:

I prefer:

See Also:

GBE Jargon Buster

#HCAOVERHEATING

@HCAUK

However if walls are not masonry but timber or light metal framed with light claddings, then the sun’s rays will have a very different effect.

The same effect occurs on timber or metal-framed roofs.

Sun’s rays falling on the cladding will warm the cladding, depending upon the materials of the cladding it will then:

Reflect

Refract

Absorb

Convection

Conduct and/or

Re-radiate

…the heat outwards to air or inwards towards the core construction, attic or interior spaces causing overheating.

See Also:

GBE Checklist

GBE Jargon Buster

Building Regulations require permanent ventilation to allow any moisture build up in attics to escape.

Eaves ventilation is a simple method it allows wind pressure to pass through the roof via eaves on both sides.

Ventilation needs to occur at the eaves and other perimeters: gables and parapets or abutments to ensure cross flow.

Ventilation may also be needed up the slope or at the ridge to address hot air rising.

Historically 1 to 3 finger wide gaps were used at eaves and verges.

Plastic parts were invented for predictable, dedicated and deliberate roof perimeter ventilation and costs rose.

Roofing underlays are designed to catch any rainwater entering under tile or slates, shingles or shakes.

Roofing underlays were made of bitumen impregnated natural fibre meshes and are heavy to carry to the roof.

BRMs are moisture permeable but rainwater and air tight, they are lightweight and easy to carry to the roof.

BRMs were introduced and considered as a low cost alternative to perimeter ventilation for moisture release.

However the second serendipitous benefit of roofing underlays and eaves ventilation is releasing heat, but this has been forgotten.

Ventilation for overheating roofs remains an important issue.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: H60-H69 Roofing Felts

GBE Robust Specification

Various membranes are used to manage risks of condensation in construction in different ways, by:

For vapour-closed construction: (Common in UK design thinking and construction application)

For vapour open construction: (Common in EU design thinking and construction application)

All membranes need integrity at overlaps, junctions, abutments and if the construction is not layered then also at services interfaces.

Vapour barriers are notoriously badly sealed at services interfaces and in some cases only lapped at overlaps.

Air and wind tightness membranes are significantly better served by a comprehensive set of adhesives, sealants, tapes and grommets.

These accessories must all be as competent as the membranes, especially when subjected to daily and yearly cyclical overheating and cooling, moistening and drying cycles, all trying to destroy the integrity of those seals.

There is PhD research that suggests combining BRMs without eaves ventilation does not work.

There is PhD research that suggests BRMs are incompatible with bats roosting in roofs

The subject of a future GBE Issue paper.

In Europe they have developed ‘Intelligent’ airtightness and wind tightness layers whose moisture permeability varies with atmospheric conditions: in winter more closed, in summer more open.

So called ‘Intelligent membranes’ perform differently in different weather conditions:

See Also:

GBE Checklist

GBE Jargon Buster

GBE CPD: P14 Airtightness of Building Elements:

GBE Products: P14 Air/Wind tightness systems, membranes and accessories

GBE Robust Specifications: JP14 Air/Wind tightness systems Specification & Guidance Notes.

The construction was water and water vapour permeable without damp proof courses and damp proof membranes and air leaky with airbricks, air leaky windows and under floor ventilation to:

Reduce risk of moisture vapour build up

Reduce risk of mould

Supply fresh combustion air to open fires and boilers

Supply cool air to food storage

Today with higher expectations of life style we do not like drafts:

Windows are more airtight to avoid drafts

Windows are more energy efficient to reduce down drafts and improve comfort conditions

Vapour barriers are commonplace (but should be added to old buildings with caution)

Breather membranes are essential if vapour barriers are used

Fitted carpets are commonly added (higher risk of asthma)

But hardwood and laminate flooring is also popular

Fridges and freezers are normal

Balanced flues are commonplace reducing drafts and improving comfort conditions

Increasing costs of heating and carbon reduction targets mean we need to be more energy efficient.

Airtightness measures will be applied but we need to be aware of these historic objectives, construction methods and materials when designing new interventions in old building to ensure we do not get things wrong.

See Also:

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

GBE CPD: Retrofit Objectives

We are now encouraged to reduce air leakiness of construction which is the same as improve airtightness of construction.

The Building Regulations Approved Document L (‘Part L’) is woefully inadequate and so is the construction sector in delivering against them, generally.

The current pass level is 10, whilst a library with a better score of 8 is unusable in windy weather due to wind noise and papers fluttering and being blown off tables.

Passivhaus energy design standard requires a pass rate of:

Balanced flue boilers provide dedicated combustion air supply.

Fridges and freezers provide dedicated food cooling and freezing.

Well insulated and ventilated pantry has been

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: Passivhaus and EnerPHit accredited products, Or Equivalent Products,

GBE Robust Specification

GBE Code: Design Standards

GBE Code: Briefing Tool

By others:

The risk associated with increasing airtightness include:

Everybody that understands how to make high performance competent buildings knows they the building needs to do most if not all the work and services should do the bit the building cannot achieve.

When we fail to invest and build cheaply we become heavily reliant upon services.

When we build somewhere in between we insulate to a level that sees a significant reduction in energy demand and a low level services intervention.

Building fabric should be as competent as possible.

We should be using air and wind tight membranes, tape, sealants and grommets to maintain the integrity of membranes at changes of direction, junctions, boundaries, and service pipe penetration crossings.

Ventilation should be deliberate and purposeful, not unintended or fortuitous.

Passivhaus and EnerPHit require mechanical ventilation with heat recovery to be installed.

It is required to be low level, high performance, high efficiency, high heat recovery,

Mechanical ventilation with heat recovery works well in winter to reduce heating to close to zero.

MVHR must be easily visibly and appreciably controllable:

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: P14 Airtightness systems

GBE Services: Passivhaus and EnerPHit MVHR

GBE Robust Specification

Simplification is desirable, simplification of service pipe penetrations through proofing membranes, avoiding the need for fire, acoustic and thermal proofing and air resistant grommets and sealants that may be prone to premature failure.

Avoiding out of sequence working and high risk of late arrival of services components interfering with completion of damp proof membranes, other proofing barriers, floor wall or roof construction and finishes.

Simplification is desirable, simplification in building walls, cutting chases, inserting conduit, rendering in, plastering over and painting walls and then feeding cables through conduit.

Skirting board convector heating: heating pipes running above the floor and in front of the walls, behind skirting covers with ventilation slots.

An alternative approach is to layer the construction and services so none of those complications occur.

Dado linings and hollow skirting and dado sections creating places for wiring outside of the wall thickness.

Timber framed walls with a second lining and batten zone inside of the wall creates a place for services without compromising vapour barriers and airtightness membranes.

The batten zones created need to be insulated or they become a route for thermal bypass and heat loss to space where it was delivered by the services.

Thermal bypass allows heat to move to other parts of the building where they may build up and lead to overheating.

See Also:

GBE Products: P20, T32 & T99 Skirting board convector heating

GBE Robust Specification

GBE CPD: Design to Reduce Waste

Hot or hot and humid spaces are beneficial for roosting bats and maternity roosts in particular.

Hot dry spaces will ensure that timbers never reach high moisture content levels and not become vulnerable to rot.

Hot spaces can be a source of renewable heat.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: Q53 Bat boxes, Bat entrances,

GBE Robust Specification

GBE CPD: Bats Beds and ZEDs

GBE Library: Bat and Bird Book

GBE CAD: 3D Cutaways

The labyrinth of battens and counter-battens below tiles or slates is a potential source of renewable heat

See Also:

GBE Checklist

GBE Jargon Buster

GBE Case Study: Scottish project that extracted 8 degrees heat from below slates for preheating hot water in winter

GBE Case Study: TSB Retrofit for a Future project in Peterborough.

GBE CPD: TSB Retrofit for a Future project in Peterborough.

Historically tiling underlay was not used and roofs ventilated easily between the tiles, creating a breezy, dark but magically illuminated roof space.

Alas underlays were introduced to minimise risk of wind blow rain entering the roof and falling on the ceiling and insulation, instead the rain would be channelled to the eaves to discharge.

But roofs immediately change to airtight except for the continuous eaves 50 mm gap:

Additional measures need to be in place to deal with wind-washing at the eaves.

In Scotland softwood sarking boarding is applied over the roof timbers this made sure the stronger winds had little effect on the interior, the roofing underlay is applied over counter-battens over the softwood sarking.

I have not entered a Scottish roof space to feel if they are any cooler due to the decrement delay by the softwood, it may only have limited effect.

Additional ventilation of the attic is necessary because they overheat in summer.

Perimeter moisture ventilation potentially provides ventilation to remove the solar heat gains.

However this is not normally sufficient and more has to be done.

Ideally there is also ventilation at the ridge or on the slopes to release rising hot air.

But more importantly, sufficient ventilation is needed to deal with significant solar heat gains.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Materials: Softwood, Sarking, Battens and Counter-battens

GBE Products: P10 Dense wood fibre insulation board

GBE Robust Specification

The usual means to protecting cold water in storage tanks from frosts in winter in attics, is thermal conductivity insulation wrapped around the sides and over the top of the tank and no thermal conductivity insulation below the tank platform, allowing heat from the accommodation below to pass through the ceiling to the underside of the tank platform to warm the soffit of the platform and hence the tank and the contained water.

The thickness of insulation to tanks is usually insubstantial, compared to ceiling insulation.

There seems to be little interest in this insulation and the bulk of the water may justify it being ignored.

In reality the crucial part of this system is to insulate between the perimeter of the tank platform and the ceiling or the heat lost from the accommodation below just spreads out from below the platform to the whole attic space and cross ventilation will remove the heat.

This is a substantial source of heat loss from the accommodation below in winter, 3 times the area of heat loss through uninsulated loft hatches; and a substantial route for heat gain to the accommodation below adding to summer overheating.

If solar radiation resistant thermal insulation is required to the ceiling then the same insulation type should be applied to the perimeter of the tank platform and to the cold-water tank.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Materials: Softwood, timber panel products

GBE Products: P10 cold water tank thermal insulation, tank deck perimeter insulation,

GBE Defect Analysis: Water storage tank Insulation

GBE Robust Specification

The usual means to protecting top floor accommodation from air leakage and heat loss to attics in winter, is thermal conductivity insulation between ceiling joists and over ceiling joists.

The risk is that no thermal conductivity insulation is installed above the attic access hatch, allowing heat from the accommodation below to pass through the hatch into the attic and cross ventilation will dissipate the heat.

This is a substantial source of heat loss from the accommodation below in winter, and a substantial route for heat gain to the accommodation below from summer overheating in the attic.

Attic hatches should also be weather stripped and latched to pull the hatch tight to the weather stripping and preventing air pressure buffeting lifting the hatch.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Materials: Softwood, timber panel products

GBE Products:

GBE Defect Analysis: Water storage tank Insulation

GBE Robust Specification

Access for inspection and maintenance of:

All these need walkways or crawl-ways installed above increasingly thick thermal insulation.

Storing possessions in the attic is commonplace and the structural design of roofs always requires the timbers to be sized to carry a 25 kg/m2 load.

Once attics have been insulated at flat ceiling level the storage space is lost.

There may be a temptation to a reuse the attic for storage in which case problems occur:

Products are now available to create raised access ways and storage platforms above thick insulation.

They include:

They solve one aspect of the possessions-in-situ problem:

The other aspect of the possessions-in-situ problem:

The stilts and the air space within section profile potentially make a thermal bridge through the insulation for 2/3rd of the insulation depth where it is warmer in winter keeping the heat in.

The stilts and the air space also provide a route down for solar heated attic air to penetrate towards the space below.

Plastic stilts with H profile maintain air paths within web spaces small enough that they are unlikely to get insulated when insitu, without a labour intense process.

50 x 50 x 5 mm stilts occurring at 1200 x 600 mm centres is:

50 x 50 mm softwood stilts may be:

Potential improvement to these systems include:

See Also:

GBE Checklist

GBE Jargon Buster: Repeating Thermal Bridge

GBE Materials: Softwood, timber panel products

GBE Products:

GBE Defect Analysis: Water storage tank Insulation

GBE Robust Specification

A common repeating thermal bridge is where e.g. stilts bridge a layer of insulation in an element.

As this occurs regularly throughout the element, i.e. the ceiling, this is deemed a repeating thermal bridge and must be accounted for in the U Value calculation for the element by making the appropriate corrections.

See Also:

Building Regulations Approved Document L1A.

Luminaires are often fitted to ceilings by cutting a whole in the ceiling and the luminaire is fitted flush with the bottom surface and projecting above.

Most luminaires are not thermally insulated to maintain the integrity of any ceiling thermal insulation, and can create a thermal bridge between the warm room below and the cold floor, attic or roof above.

Some luminaires are not airtight enclosures, sometimes deliberately to ensure there is no heat build-up in the luminaire which may reduce the life of the light-bulb or even the luminaire; connecting the space above and below.

Air passing through a luminaire will carry heat and moisture vapour, reducing the energy performance of the building.

For high performance buildings it is essential to reduce air leakage and heat flow.

Luminaires will occupy the space of insulation above the ceiling so extra insulation will be needed above the surrounding insulation.

Moulded airtight housings are made to fit over the top of luminaires to make them airtight and stop heat flow.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

In the last 5 years there has been significant improvement in the kit and software so analysis can now be more accurate, focussed, purposeful and intentional.

Normally IRT is most often used for detecting heat loss from buildings but can also be used for detecting heat gain.

IRT can also be used in:

IRT from outside looking at external faces of the building, shows heat escaping through the building fabric, analysis will look for hot spots and other anomalies.

External view heat loss IRT is normally carried out at night after the fabric is cooled down from solar gains to avoid misleading information. Examples:

Interpretation of IRT images can be misleading and analysis of the building materials at anomalies in daylight is essential to check materials and there relative emissivity.

In the wrong hands IRT can be a misleading method for testing for overheating.

IRT can also be used for detecting heat gain.

External view heat loss images taken in the day will be misleading for a number of reasons:

Normally IRT is most often used for detecting heat loss from buildings.

IRT from inside looking at internal faces of the building show heat escaping through the building fabric, analysis will look for cold spots and other anomalies.

IRT can also be used for detecting heat gain.

IRT can be used internally looking at internal faces of the building to show heat entering through glazing and building fabric.

The heat source for IRT internal surveys of heat gain is the sun.

Internal views may well show up shadowing by adjacent buildings and trees

A recent ‘tweet’ showed an internal view of an external door during the prolonged heat wave across Europe.

But the more revealing views would be:

These images are likely to show hot ceiling, hot walls, hot roofing.

This publication was written with the help of the ZCH so unlikely to be anything different here.

I found the same issues raised by ZCH repeated, but one item caught my attention.

Case Study 4 BRE test houses made to British and Swedish building standards.

My own analysis of the BRE survey:

Infrared Thermography:

Simulated heat gains:

Solar gains:

I remember an architect including a window in an attic, the contractor thought the architect was nuts, as they do.

Upon completion he asked the architect permission to include a window in every attic he builds in future, which of course was granted.

The opportunities and advantages of having a window rather than just a vent in an attic are numerous:

A room below a well-insulated attic should not suffer from excessive heat loss via attic window trickle vents in winter.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: L10 Windows, Roof windows

GBE Robust Specification

Attic glazing could be a window, rooflights or roof window; it could be in gable walls, dormer or roof slope.

Ideally it would be placed on the northern slope or gable to maximise the daylight without sunlight.

If north is not available, choose eastern slope, dormer or gable for morning sunlight, to minimise solar light/heat gains.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: L10 windows, rooflights or roof window

GBE Robust Specification

Windows, rooflights and glazed doors will allow some of the suns rays in, reflecting or refracting some light and heat.

Then the same effect as a greenhouse comes into effect the wavelength of light changes and heat will not readily escape back out through the same glass.

So the heat builds up making the space inside hotter.

In summer this is a problem, in winter this is an advantage.

Some of the built up heat will conduct back out through the glazing and opaque construction.

In addition to the change in light frequency keeping heat inside glazing in greenhouses and buildings:

High performance glazing often includes low emissivity glass, designed to reflect heat back into buildings.

The combination of overheating and low-E glass can exacerbate the problem to increase or persist longer.

One translucent insulating glazing/cladding manufacturer, with optional glazing performances, regularly downgrades the U Value and omits Low E characteristics in rooflights over spaces if there is no heating or cooling and insufficient ventilation and risk of overheating.

Design criteria is evolving as software sophistication enables it.

By others:

Passivhaus Webinar: Passive House Windows for Mediterranean Climates https://youtu.be/YHg4Pt1M5Tw via @YouTube via twitter @JMenendez

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

Internal solar shading, inside of the glass, comes in a variety of forms:

Internal solar shading is effective at stopping summer sunlight, but they have already permitted the sun’s heat inside.

Internal solar shading ideally needs to be combined with ventilation to remove that heat.

This ventilation could be via the windows, doors, and trickle vents dealing with the problem at the point of source.

If heat is not lost at point of source, then spaces need cooling using passive, active or mechanical ventilation.

If at all possible and in all cases, we should be avoiding air conditioning.

One manufacturer makes reversible perforated blinds silver on one side black on the other:

Inward opening windows will clash with internal shading.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: N10 Reversible perforated blinds

GBE Robust Specification

GBE Services: Shutter refurbishment and upgrades

Venetian blinds can be used effectively when contained within double glazed or double casement windows.

The blind is controlled room-side with cleverly included pull cables.

The blind is enclosed so never gets dusty and remains untouched, undamaged and of consistent appearance.

The blind provides choices between: privacy v view, darkness v daylight, shade v sunlight, coolth v heat.

If the blind is between casements the void could be ventilated to the exterior.

Encapsulated blinds do not clash with inward or outward opening windows

This is a multi-functional, cost effective solution that could survive value engineering, cost cutting and substitution.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Case study: Elizabeth Fry student accommodation, UEA, Norwich.

GBE CPD: L10 Windows

GBE Products: L10 Windows with encapsulated blinds

GBE Robust Specification

Once inside the sun’s rays will fall on the adjacent floors and walls within eyesight of the sun.

If the floors are made of any of the following then the floor will soak up the heat:

Floors will absorb heat over sun bathed surface areas, gradually warming from the exposed face into the thickness.

Heat absorption will continue until it reaches saturation point or it reaches any insulation layer

Heat absorption will stop when sun’s path moves out of eyesight of the floor area and there is no more heat to add.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Lectures: Elements: (23) Floors

GBE Products:

GBE Robust Specification

Low thermal mass floor surfaces prevent heat absorption into the finish or substrate (base) to varying degrees and less advantage can be taken of solar light/heat gains.

Insulating screeds and insulating concrete or alternative concretes will not heat up as much as dense concrete.

Timber floors:

Carpets with or without underlays

Raised Access Platform floors hide the supporting thermal mass floors away from the sun’s rays.

Spaces below platform floors used as plenum spaces could exploit thermal mass if the ventilation is designed to deposit heat in the floor and purge it at another time, but that needs a level of coordination between disciplines, not often seen.

Suspended ceilings hide the supporting thermal mass floors away from the sun’s rays.

Spaces above suspended ceilings used as plenum spaces could exploit thermal mass if the ventilation is designed to deposit heat in the floor and purge it at another time, but that needs a level of coordination between disciplines, not often seen.

Steel trough permanent formwork soffits of composite steel and concrete floors prevent exploitation of thermal mass of concrete floors from below

See Also:

GBE Checklist

GBE Jargon Buster

GBE Lectures: Elements: (23) Floors

GBE Products:

GBE Robust Specification

The same applies to any adjacent sun kissed walls, if the walls are made of cement, lime, gypsum or clay render, plaster or finish they will absorb heat to varying degrees depending upon thickness and density and their substrate (background); however insulating or light plasters and renders will not absorb as much as dense.

If the wall is dry-lined with:

By virtue of the isolation framework, levelling battens, counter battens or dabs the board is substantially isolated from the background, dry-lining boards can absorb the heat but will not be able to pass it on into the substrate material so have restricted mid-term effect.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Lectures: Elements: (21) Walls

GBE Lectures: Elements: (22) Partitions

GBE Products:

GBE Robust Specification

In social media I spotted an autoclaved aerated concrete block manufacturer noting the hottest day on record and smugly asking how many people complaining about the overheating were living in timber framed houses.

This needs taking apart and understanding, it might assume…..:

Conclusion:

See Also:

GBE Checklist

GBE Jargon Buster

GBE Lectures: Elements: (21) Walls

GBE Lectures: Elements: (22) Partitions

GBE Products:

GBE Robust Specification

Thermal mass works at different time scales:

Serviced heat stores are a separate set of solutions.

See Also:

GBE Checklist

GBE Jargon Buster

Heat has to be absorbed by the surface into the material and on into the thickness.

Thermal mass is not well exploited when it is small in area and thick.

Thermal mass is most effective when it is large in area and thin: walls, floors and ceilings are potentially effective.

Steel trough and concrete composite floors will not absorb heat from below

See Also:

GBE Checklist

GBE Jargon Buster

GBE Lectures: Elements: (21) Walls

GBE Lectures: Elements: (22) Partitions

Mid term elemental core thermal mass works at weekly, monthly or seasonal scale, progressively warming from winter to summer and cooling from summer to winter.

Heat has to be absorbed by the surface into the material and on into the thickness.

Over the year the average daily temperatures rising towards summer, will raise the temperatures of the element cores offering thermal inertia.

Opening windows to cool a space will only cool the air (if the outside air is cooler) once the windows are closed the exposed thermal mass will rewarm the space rapidly.

See Also:

GBE Lectures: Elements: (21) Walls

Long term external thermal mass works at inter-seasonal time scale.

Thermal mass of subsoil around a buried or bunded building is exploited; no thermal insulation is used between building and subsoil.

Thermal insulation is located beyond the subsoil so that heat can be stored in the subsoil around, behind, above and below the building.

The summer heat warms the building fabric and then passes through the floor and walls into the subsoil.

Heat can penetrate the right types of soil at about 1 meter per month; 6 months of heating will warm 6 meters of soil.

Insulation needs to surround and corral 6 meters of subsoil.

Ground water movement could remove the heat so that needs to be considered in the geometry of the insulation.

The geology (subsoil types) and topography (surface profiles) of some geographical areas (locations) are better than others:

See Also:

GBE Checklist

GBE Jargon Buster

GBE CPD: Zero Energy Building

GBE Products: E20 Below ground conductivity thermal insulation

GBE Robust Specification

Serviced heat stores are a separate set of solutions and come in a variety of formats

See Also:

GBE Checklist

GBE Jargon Buster

GBE CPD: Zero Energy Building

GBE Products: Heat store systems

GBE Robust Specification

When we had a domestic hot water cylinder fail it needed replacing the service agreement meant British Gas were called out to do their best.

The rather battered foam insulated cylinder was replaced with a new thickly insulated package with polyethylene sheath surrounding mineral fibre conduction thermal insulation and copper cylinder.

British Gas pays millions on endless TV advertising persuading us they are the right people for the job

The Engineer promptly informed us that he did not believe in thermal insulation on domestic hot water systems:

Pipe lagging or lack of it is another source of heat adding to the overheating problem.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: Y50 Pipe insulation and Cylinder insulation

GBE Robust Specification

Hocketon Housing Project (HHP) has an effective Heath Robinson solution for domestic hot water.

HHP use a 1m3 plastic drink container as a heat store (usually contained in a metal cage for transport) with 300 mm conductivity thermal insulation surround to keep it hot.

The heat store being well insulated, avoids overheating the house (which is itself well insulated and could readily overheat if this heat was not well contained).

The water inside is the heat store is held at 40 degrees C the temperature the hot water will be used at, avoiding using more energy than necessary to heat the water to a higher temperature, and avoiding adding cold to be able to use it.

Investigate the heat source: no ST panels visible, PV & Wind turbine were added later, did the MVHR provide excess heat?

A separate pipe passes through the heat store, domestic cold water passes through the pipe, heat transfers from the heat store into the cold water, domestic hot water is passed along well insulated short pipes to the kitchen sink, ?washing machine?, wash basins and shower.

Pipe runs are not buried in construction (in or under concrete floors, under ceramic tiles, in blockwork walls) but adopting the layered construction approach.

Pipes are inside the spaces, boxed into ducts and very well insulated, accessible to repair, maintain and upgrade.

Pipes do not pass through vapour barriers, breather membranes, damp proof membranes, and thermal insulation; do not make air leaks or thermal bridges.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

GBE CPD: Hocketon Housing Project (HHP)

Heat stores have evolved from rocks to salt to phase change materials including waxes.

Today vessels with the right recipe of wax for optimum energy storage and release are used effectively.

They are added to energy management systems that monitor inputs (renewable heat and renewable energy) and demands (heating and hot water) and optimise the use each is put to.

Whenever there is excess heat to requirements it can be put into the heat store by passing the heat through pipes running through the storage media and transferring heat to the media.

When there is insufficient heat to match demands the process can be reversed and the heat drawn out of the storage media.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products: T50 & Y21 Heat stores for central heating

GBE Robust Specification

As some begin to make competent buildings (Passivhaus, EnerPHit, Minergie and SuperE) the high levels of thermal insulation means heat loss is down to a minimum.

The next slice of the energy consumption cake that needs to concern us is hot water.

We need to insulate the domestic hot water pipes and vessels to similar levels of efficiency or their heat might tip the balance to create overheated buildings.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE ToolBox: Passivhaus, EnerPHit, Minergie and SuperE,

GBE Robust Specification

Pipe lagging or lack of it is another source of heat adding to the overheating problem.

Historically (1960’s housing for example) hot pipes were buried in screeds and run in floor and attic voids without insulation squandering excessive amounts of hear where it was not needed, added to overheating, or was lost to the atmosphere.

In winter heat loss to the building fabric will potentially warm the interior of the building but just as easily warm the voids in the construction or the atmosphere.

In summer heat loss to the building fabric will potentially warm the interior of the building when you least require it.

Today pipe runs should not be buried in construction (in or under concrete floors, under ceramic tiles, in blockwork walls) but adopting the layered construction approach.

Pipes carrying hot water buried in construction lose heat into that construction, rather than deliver it the intended location.

The only exception to this is deliberate under-floor heating where the pipe is cast-in to transfer heat to the fabric effectively.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

Pipe lagging or lack of it is another source of heat adding to the overheating problem.

Domestic hot water pipes are often long runs between cylinder and bathrooms and kitchens in poorly planned house layouts.

These uninsulated pipe runs mean we run a lot of hot water from cylinders towards taps before the hot water arrives, as soon as the tap is turned off, the long run of pipe filled with hot water then looses its heat into the construction, ducts or voids or to the atmosphere.

Today British Gas Engineers replacing hot water cylinders are only obliged to insulate the first meter of pipe from the cylinder.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

When lagging is so labour intensive and costly it makes sense to consider alternatives.

When pipe insulation is often pre-manufactured to be small section and consequentially ineffective, alternatives should be considered.

Filling a duct space including getting around the back of the pipes is easier than lagging the pipe.

Filling the duct space offers greater insulation to resist heat loss,

Creating filled voids with no air movement and no eddy currents stops thermal loss to the voids and dissipation.

Every little loss of heat helps to minimise the cumulative overheating from many sources.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

The Construction shows where National and International Plumbing Apprentices of the year competitions occur, judge their skills on their pipes but never on their insulation work.

Donated appliances and materials are never the water saving or energy saving varieties or versions.

This may be indicative of the curriculum content and the skills acquired.

Multi-skilling of tradesmen is severely frowned upon by the skills councils, who control the curriculum of apprentices.

Multi-skilling is allegedly eroding the skills of any one tradesman.

And maybe it is all about protectionism looking after jobs?

They do not want multi-disciplined low skilled tradesmen out there.

But the system we have adopted does not control cowboy builders.

This does not prepare our workforce for reality and the enormous programme of work under Energy Company Commitment (ECO) if it has not been killed off and GreenDeal if it ever starts.

Our workforce is discouraged from carrying insulation with them when they know they will be opening up ducts, floors, walls and roof to find uninsulated pipes.

Instead they are expected to do their plumbing and electrics then close up the ducts ignoring uninsulated pipes and uninsulated voids that potentially create thermal bridges.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

GBE Applicators and Installers: Trained Approved Accredited

Lagging in prevalent use in the 1960’s was made of loose woven hessian strips; it is ineffective as conduction thermal insulation.

There was very little of it (thickness) and it was labour intensive to wrap around a pipes if unrestricted and almost impossible if against a wall or floor, so the temptation to do very little of the pipe (length) was real.

If inspection happened it would only occur for those parts easily inspected, the vast majority remaining uninsulated.

In domestic buildings the specifications might well ask for insulation on domestic hot water and heating pipes but very few people police it and it does not happen.

Speculative housing developers know the pipes will not be insulated even if specified, they do not want to pay for something they are not getting; so they do not specify it, do not get it and do not pay for it.

The DIY market sells extruded hollow foamed plastic or rubber conduction thermal insulation for small size pipes.

And the pipe runs are predominantly inaccessible.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

In commercial buildings the specifications require insulating and identification labelling of pipes carrying heat or coolth amongst others.

Inspection is likely to happen so it might be fair to assume insulation happens, at least where it is on show and easily inspected.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

Since hot water and heating services are a significant source of heat that can contribute to overheating, it is recommended that they be designed to be more accessible, insulate able and upgradable, than has been common to date.

Service ducts behind walls or between serviced rooms are commonplace in offices.

Services ducts could become common in homes but they may be smaller to suit the nature and content of the services required.

Integer house at BRE campus has:

BedZED has:

Hollow voids created need to be insulated or they become a route for thermal bypass and heat loss to spaces where it was not delivered by the services.

Thermal bypass allows heat to move to other parts of the building where they may build up and lead to overheating.

See Also:

GBE Checklist

GBE Jargon Buster

GBE Products:

GBE Robust Specification

GBE Case Study: Integer House at BRE campus

GBE Case Study: BedZED

Adding conduction thermal insulation or acoustic insulation into ground and upper timber floors and accommodating services is simple enough except the physical action is fiddly.

For a long time now nylon meshes have been stapled to the tops of joists and slung between the joists creating a hammock to fill with insulation.

But if you watch anybody installing them your will observe a fault that develops as the job progresses.

The first few joist spaces work okay but as they progress across the floor they push down on the mesh to create the required depth in the current hammock, and the insulation in the first and subsequent joist spaces progressively rise above the joist zone.

What is happening is the nylon mesh is pulled and slips through the staples shortening the length one side of the staple reducing the capacity of the hammock.

When the softwood boards are relayed the insulation above the joists becomes compressed and ineffective.

Ineffective insulation allows heat or coolth to transfer more readily and overheating can happen more easily.

There are rigid scored and foldable sheets that can be stapled into place to support the required thickness of insulation without the risk of slipping and compressing, thus allowing effective conduction thermal insulation.

See Also:

GBE Checklist