Gyvlon Screed Product

GBE > Encyclopaedia > Products > Products All > G#10522

Gyvlon Screed Product

Tabs including * indicates there is information for this Product

- 1 Images

- 2 About Product *

- 4 PASS Product Accessory System Screening

- 5 HERACEY (TM)

- 6 Manufacturers Downloads *

- 7 Product Data Sheet

- 8 BIM CAD Model

- 9 BIM Product Data Sheet

- 10 COBie Spreadsheet

- 11 Product Specification *

- 12 Application Data Sheet

- 13 Accessories

- 14 Systems

- 15 Elemental Assemblies

- 16 Elemental Assembly Specification

- 17 Workmanship Specification

- 18 Waste Specification

- 19 FM Spec In Use Maintenance Specification

- 20 End Of Life Options

- 21 Products Passport

- 22 See Also

- 23 Echo *

- 3 Incubator *

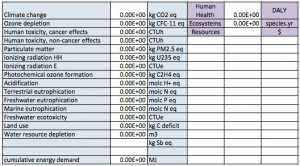

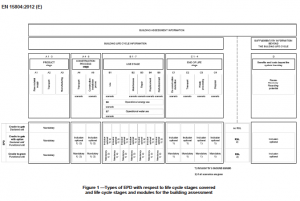

- 24 LCA and EPD

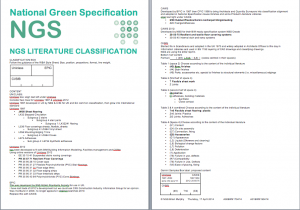

- 25 Classify

- 26 Manufacturer *

- 27 Supplier *

- 28 Installer/Applicator *

- Pending

- Product

- Packaging

- Delivery

- Mixing

- Installation

- Complete

%%%Pending

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

3rd December 2015 – 5th December 2015

Gyvlon Screed Product

About:

From manufacturer’s website:

SCREED SOLUTIONS:

In construction, anhydrite can advantageously replace traditional cement, as a binder for screed mortars.

Anhydrite is widely used in floor screed applications because of its numerous advantages:

- better fluidity for self-leveling

- greater dimensional stability

- high mechanical strength

- outstanding thermal conductivity

- GBE Product Page G#529 N#549

- GBE Product Data Collection Sheet

- GBE Product Data Sheet

- PRODUCT SPECIFICATION CLAUSE TITLE

- Product Description (Manufacturers Marketing Opportunity)

- Promote properties other than environmental, accreditations, etc.

- Promote size, colour, texture ranges etc.

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

19th March 2016 – 5th November 2020

- G#515 N#533 GBE PASS

- G#747 N#769 GBE PASS Navigation

GBE Jargon Buster

- G#1057 N#1074 GBE PASS Products Accessory System Screening

- PASS Schedule

- Product

- Accessory

- System

- Screening

- %%%Pending

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

3rd December 2015 – 7th December 2015

Gyvlon Screed

GBE Library

UK

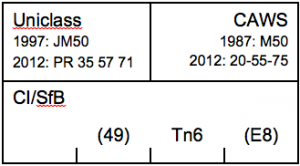

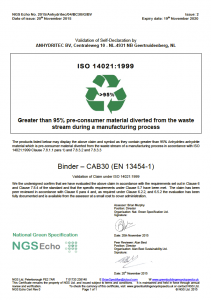

Certificate Binder CAB30 UK Ltd v6

CAB 30 Binder Anhydritec Ltd. UK

Holland The Netherlands

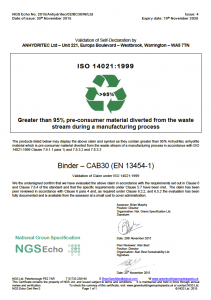

Certificate Binder CAB30 NL GmBH v6

CAB 30 Binder Anhydritec GmbH Netherlands

Certificate Binder CAB30 NL BV v6

CAB 30 Binder Anhydritec BV Netherlands

France

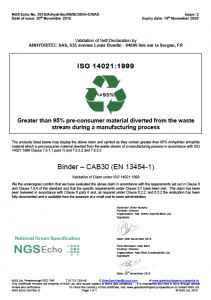

Certificate Binder CAB30 FR SAS v6

CAB 30 Binder

Anhydritec SAS France

- Brochure (See Manufacturer page)

- Promotional Literature

- Technical Literature

- Specification

- CAD Files

- BBA Certificate

- ETA Certificate

- CE Mark Certificate

- Green Label

- Health Label

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

19th March 2016 – 5th November 2020

- G#543 N#563 GBE Product Data Sheet

%%%Pending

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

3rd December 2015 – 13th December 2015

- G#452 N#458 GBE BIM

- Product Object

- System Assembly

- Elemental Assembly

- BIM Products Data Sheet (This page tab 9)

- Digital Object Identifiers (DOI)

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

3rd December 2015 – 13th December 2015

- GBE BIM Product Data Sheet

Selected from CIBSE BIM Product Data Sheets or developed to suit

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015 – 13th December 2015

- GBE BIM COBie Data Sheet

- COBie Excel Spreadsheet

- GBE Excel Short Spreadsheet

- Short code URL

- GBE Repository for LCA data for Environmental Cell

- GBE 301 Redirect file to maintain links

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015 -13th December 2015

Gyvlon Screed Product

GBE Robust Specification

Draft Specification

M13 CALCIUM SULFATE BASED SCREED

To be read with Preliminaries A10-A55/General Conditions

110A SYNTHETIC ANHYDRITE BINDER

- Manufacturer: Anhydritec Ltd. 221 Europa Boulevard, Westbrook, Warrington, WA5 7TN

- Telephone 01925 428780 Fax 01925 428788

- E contact@anhydritec.com W www.anhydritec.com

- Product Reference: ______ Binder

- Manufacturing standard: EN 13454-1 Mechanical Resistance: CAB30

- Binder: Anhydrous calcium sulfate based binder

- LCA or EPD to ISO 14025: None

- Country of manufacture: Manufactured: EU various, Binder Processed & Blended: UK

- Manufacturer’s Self-declaration:

- Resource efficiency: >95% pre-consumer material diverted from waste stream during a manufacturing process

- Independent confirmation of manufacturer’s self-declaration: NGS Echo 20/11/2015

- The main ingredient for Gyvlon is a bi-product of the chemicals industry.

- In the past, this bi-product would have gone to landfill or worse.

- Resource efficiency: >95% pre-consumer material diverted from waste stream during a manufacturing process

120A PUMPABLE SELF-LEVELLING SYNTHETIC ANHYDRITE SCREED:

- Manufacturer: Anhydritec Ltd. 221 Europa Boulevard, Westbrook, Warrington, WA5 7TN

- T 01925 428780 F 01925 428788

- E contact@anhydritec.com W www.anhydritec.com

- W www.gyvlon.co.uk

- Product Reference: Gyvlon Screed (which one(s)? One per page!)

- 3rd party product endorsement: BBA, (Gyvlon Screed, Gyvlon ECO and Gyvlon Thermio+)

- Application: Codes of Practice: BS 8204:Part 7 Pump-able Self-leveling screeds & BBA Certificate

- Binder: Synthetic Anhydrite binder to M13/110A

- Aggregate: ______

- LCA or EPD to ISO 14025: None

- Country of manufacture: Manufactured: EU various, Binder Processed & Blended: UK

- The main ingredient for Gyvlon is a bi-product of the chemicals industry.

- In the past, this bi-product would have gone to landfill or worse.

- Manufacturer’s Self-declaration:

- Resource efficiency: >95% pre-consumer material diverted from waste stream during a manufacturing process

- Independent confirmation of manufacturer’s self-declaration: NGS Echo 20/11/2015

- Anhydrite based screed is used as a replacement for sand/cement screeds:

- Cement replacement with anhydrite avoids the use of:

- High embodied energy and embodied carbon cement

- Virgin aggregate sand and fine aggregate

- Avoiding the use of sand/cement screeds avoids their weaknesses:

- Drying shrinkage, curling and cracking

- The need for joints and reinforcement

- The need for different recipe and methods for different thicknesses

- Long curing and drying times and subsequent delay to following trades

- Using a self-levelling screed enables:

- Faster installation than hand-applied screeds (x10);

- Using anhydrite based screed:

- Offers overnight initial set and fast hardening and drying times

- Enables early deployment of following trades the next day without risk

- Application: pumped self-levelling floor screeds.

- Historically large open floor spaces were desirable to be cost effective, but today much smaller areas are practical so

- Anhydrite based screeds are now entirely appropriate for more cellular houses.

- Anhydrite based screeds perform particularly well with piped under floor heating systems.

- Using Gylonmobil on-delivery vehicle, controlled mixing plant:

- Enables exact quantities required to be mixed on site with no wastage.

- Life expectancy: Lifetime of building (claimed where? BBA)

- End of Life: Recyclable: No

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

19th March 2016 – 5th November 2020

- GBE Application Data Sheet

Based on CAPEM Data Collection Sheet

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- CLAUSE:

- %%%pending

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015

GBE Jargon Buster

- N#1275 Accessory/Accessories

- Masonry Accessories

- Carpentry Accessories

- Fixings and Fasteners

- Reinforcing and Proofing:

- Reveals, Edges and Corners, Skirting and Coving

- Adhesives

- Sealants

- Tapes

- Gommets

- Gaskets

- Proofing:

- Fire Proofing

- Acoustic Proofing

- Thermal Proofing

- Moisture Proofing

- Water Proofing

- Gas Proofing

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- ACCESSORY SPECIFICATION CLAUSE TITLE (from 2 About Products)

- Application: [System/Subsystem/Elemental Assembly]: [________]

- Use with Products: [________]

- Manufacturing Standard: [BS/EN/ISO] [________]

- [Agrement /EuroAgrement Certificate No.]: [________]

- European Technical Approval: [________]

- Technical Literature: [________]

- Properties: [________]

- Manufacturer: [________]

- Product Reference: [________]

- Model number: [________]

- Size: [___x___x___]

- Schedule: [________]

- Finish: [________] to work section [____]

- Colour: [________], [BS 4800/RAL]: [________]

- Gloss level: [____] % +/- [__]%

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015 – 13th December 2015

- GBE Systems

GBE Jargon Buster

- G#1265 N#1262 Systems (JB)

- Products

- Accessories

- Elemental Assemblies

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- SYSTEM SPECIFICATION CLAUSE TITLE (from 2 About Products)

- Reference Drawing(s): [_______] (left blank for project editor)

- Location: [_______] (left blank for project editor)

- System Assembly:

- Product(s): to [____/____]

- Accessories: to [____/____]

- Elemental Assembly: [________]

- Legend Reference Number: [________]

- Substrate: [_______] (left blank for project editor)

- Preparation: [_______] (left blank for project editor)

- Application: [________]

- Specification

- Schedule

- Method Statement:

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015

- G#1226 N#1227 GBE Elemental Assemblies

GBE Jargon Buster

- N#1618: B03 Elemental System Performance

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- ELEMENTAL ASSEMBLY CLAUSE TITLE:

- Legend Element Reference: [________]

- GBE BEACON: [________]

- Reference Drawing(s): [_______] (left blank for project editor)

- Location: [_______] (left blank for project editor)

- Schedules: [________]

- Elemental Performances: to [________]

- Prior Element: [_______] (left blank for project editor)

- Prior trade sign off: [________]

- Substrate: [_______] (left blank for project editor)

- Preparation: [_______] (left blank for project editor)

- Components: (bottom to top; outer, core to inner)

- Sub Assembly System: Below: [________] to [____/____]

- Core Assembly System: Horizontal: [________] to [____/____]

- Sub Assembly System: Above: [________] to [____/____]

- Sub Assembly: Outer: [________] to [____/____]

- Core Assembly System: Vertical: [________] to [____/____]

- Core Assembly System: Pitched: [________] to [____/____]

- Sub Assembly: Inner: [________] to [____/____]

- Testing: [________]

- Following trade sign off: [________]

- Protection: [________]

- Protection: maintenance/checking: [________]

- Protection Removal: [________].

- Cleaning: [__________].

- Other requirements: [________].

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015 – 13th December 2015

- Elemental Assembly Specification

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- ELEMENTAL ASSEMBLY SPECIFICATON CLAUSE TITLE:

- Legend Element Reference: [________]

- GBE BEACON: [________]

- Reference Drawing(s): [_______] (left blank for project editor)

- Location: [_______] (left blank for project editor)

- Schedules: [________]

- Elemental Performances: [________]

- Prior Element: [_______] (left blank for project editor)

- Substrate: [_______] (left blank for project editor)

- Preparation: [_______] (left blank for project editor)

- Components: (bottom to top; outer, core to inner)

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015 – 7th December 2015

- GBE GBS Workmanship Specification

- ISO Code of Practice

- EN EuroCode

- BS Code of Practice

- BS 8000 Workmanship on Building Sites

- Industry/Sector Guidance

- Manufacturers Recommendations & Requirements

- Sequence

- Prior trade sign off

- Following Trade Sign off

- Accredited /Approved Installers

- DIY or BIY Suitability

- Sample Panels

- Control Samples

- Specification Clauses

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- WORKMANSHIP CLAUSE TITLE:

- Reference Drawing(s): [_______] (left blank for project editor)

- Location: [_______] (left blank for project editor)

- Prior Trade: [_______] (left blank for project editor)

- Substrate: [_______] (left blank for project editor)

- Preparation: [_______] (left blank for project editor)

- Specification: [________]

- Schedule: [________]

- Finish: [________] to work section [____]

- Colour: [________] RAL: [________]

- Gloss level:

- Method Statement:

- Waste clause: See [____/____]

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015 – 7th December 2015

- GBE GBS Waste Specification

- Packaging and Protection requirements

- Recycling Opportunities

- Reuse Opportunities

- European Waste Catalogue reference

- Waste Category

- Waste Recycling and Reuse Appendix

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- WASTE CLAUSE TITLE:

- %%%pending

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015

- GBE GBS FMSpec Specification clause

- CPD Seminar

- Schedule

- Method Statement

- Specification

- Availability

- Spares

- Maintenance

- Frequency

- Materials

- Tools

- COBie Data

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- MAINTENANCE CLAUSE:

- %%%pending

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015

- N#1677 GBE End of life

- Pre Alteration Audit

- Pre Demolition Audit

- Soft Strip

- Resale Opportunities

- Reuse Applications

- Reuse Accreditation

- Deconstruction

- Product Passport

- Demolitions

- Waste Category

- European Waste Catalogue reference

- Recycling Opportunities

- CAWS/NBS Building Work section: [____]

- NBS/NGS clause number: [____]

- Uniclass/NBS Create Work section: [________]

- NBS Create/NGS clause number: [________]

- END OF LIFE CLAUSE:

- %%%pending

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

5th December 2015

- G#1098 N#1116 GBE Product Passport

GBE Jargon Buster

- N#1115: Product Passport

- Product Passport

- Provenance

- Pre Alteration Audit

- Pre Demolition Audit

- Original Building

- Exposure Condition

- Orientation

- State of repair

- Quantity

- Properties

- Evidence of Properties

- Deconstruction

- Demolitions

- Palleting Packaging and Protection

- Bar Code/QR Codes

- Information Repositry

- Resale Opportunities

- Reuse Applications

- Reuse Accreditation

Jargon Buster

GBE Checklist

- M Surface Finishes Navigation

- M13 Calcium Sulfate based Screeds

Code

GBE CPD

- Floor Finishes

GBE Lectures

- (23) Floors

Gyvlon Screed Product

GBE Echo

- GBE Echo

- Manufacturer’s Environmental Self-Declaration to ISO 14021

- Independent Validation of Manufacturer’s claim to ISO 14021

- Report: Is available via local contact via contact@anhydritec.com

- Evidence Documents

- Factory Visits

- Public Disclosure Document Schedule

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

19th March 2016 – 5th November 2020

Gyvlon Screed Product

Incubator:

- The main ingredient for Gyvlon is a bi-product of the chemicals industry.

- In the past, this bi-product would have gone to landfill or worse.

- Manufacturer’s Self-declaration:

- Resource efficiency: >95% pre-consumer material diverted from waste stream during a manufacturing process

- Independent confirmation of manufacturer’s self-declaration: NGS Echo 20/11/2015

- Anhydrite based screed is used as a replacement for sand/cement screeds:

- Cement replacement with anhydrite avoids the use of:

- High embodied energy and embodied carbon cement

- Virgin aggregate sand and fine aggregate

- Avoiding the use of sand/cement screeds avoids their weaknesses:

- Drying shrinkage, curling and cracking

- The need for joints and reinforcement

- The need for different recipe and methods for different thicknesses

- Long curing and drying times and subsequent delay to following trades

- Using a self-levelling screed enables:

- Faster installation than hand-applied screeds (x10);

- Using anhydrite based screed:

- Offers overnight initial set and fast hardening and drying times

- Enables early deployment of following trades the next day without risk

- Application: pumped self-levelling floor screeds.

- Historically large open floor spaces were desirable to be cost effective, but today much smaller areas are practical so

- Anhydrite based screeds are now entirely appropriate for more cellular houses.

- Anhydrite based screeds perform particularly well with piped under floor heating systems.

- Using Gylonmobil on-delivery vehicle, controlled mixing plant:

- Enables exact quantities required to be mixed on site with no wastage.

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

3rd December 2015 – 5th November 2020

%%%Pending

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

7th December 2015

GBE Collaborative Service

G#1479 N#1440 GBE Classify

N#1441: 17/04/2014: GBE CLASSIFY:

Service to classify literature developed to Samples Box labelling

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

13th December 2015

Gyvlon Screed

GBE Manufacturer

- Anhydritec Ltd. G#10459

- ANHYDRITEC SAS, 635 avenue Louis Boudin – 84800 Isle sur la Sorgue, FR France

- ANHYDRITEC BV, Centraleweg 10 – NL-4931 NB Geertruidenberg, NL Netherlands

- ANHYDRITEC GmbH, Frankfurter Landstraße 2-4, D-61440 Oberursel D Germany

- ANHYDRITEC Ltd – Unit 221, Europa Boulevard – Westbrook, Warrington – WA5 7TN GB Great Britain

- Company Supply Chain Activities: Manufacturer/Supply Direct

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

19th March 2016 – 20th March 2016

Gyvlon Screed

GBE Suppliers

- Anhydritec Ltd. G#10459

- ANHYDRITEC SAS, 635 avenue Louis Boudin – 84800 Isle sur la Sorgue, FR France

- ANHYDRITEC BV, Centraleweg 10 – NL-4931 NB Geertruidenberg, NL Netherlands

- ANHYDRITEC GmbH, Frankfurter Landstraße 2-4, D-61440 Oberursel D Germany

- ANHYDRITEC Ltd – Unit 221, Europa Boulevard – Westbrook, Warrington – WA5 7TN GB Great Britain

Company Supply Chain Activities: Manufacturer/Supply Direct

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

19th March 2016 – 20th March 2016

Gyvlon Screed

![]()

- GBE Installer/Applicator Page

- GBE Installer/Applicator Data Collection Sheet

- GBE Installer/Applicator Data Sheet

- Installer/Applicator

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

14th December 2015 – 20th March 2016