GBE > Encyclopaedia > Code > Checklist > New Build > G#1597 N#1527

G20 Carpentry/Timber Framing/First Fixing Checklist

G20 Carpentry/Timber Framing/First Fixing Checklist

About:

Index:

Problems:

- Tree cutting is seasonal:

- unseasoned hardwood framed buildings:

- be aware of the potential for delay until next tree cutting occurs,

- plan projects around this issue

- Acidic species:

- tanning run off can stain porous materials below,

- provide temporary or sacrificial protective materials or coatings

- can corrode or stain ferrous metal fasteners or visa versa

- use austenitic stainless steel fasteners (screws/nails etc.)

Misunderstandings:

- Durable timbers do not all come from the Tropical Rain Forests

- There are durable softwoods as well as hardwoods

- Prefabrication off site does not reduce offcuts,

- but the off cuts have a greater potential to be used in a factory rather than put in a skip on site

Solutions:

- Grow trees to be available to replace roof and other timbers in 60-120 years

- Use any existing trees that are to be cut down as part of the works

Consider:

- Choose locally sourced timber:

- first > last:

- Site > Town > County > Region > Country > Continent > World

- FSC certified forest timber,

- it addresses more of the sustainability issues,

- 276 sources in the UK.

- Oak and many other species are durable and are available in the UK and Europe

- Off site prefabrication to reduce on site waste

- Design structure for appropriate life See A90

- Short life: 30 years

- Normal Life: 60 years

- Long life: 120 years:

- Design frame for deconstruction, salvage and reuse in future at end of design life. See A90

- Softwood or Hardwood in place of steel structure

- Floor structure, roof frame, decking and ramps are opportunities for timber structures made from home-grown structural timber, reducing the need for cement and aggregates on the project

- Glued laminated timber where poor strength grade timber can be substituted in the middle of the section where it is least stressed

- Potential to reduce the self weight of the section without significant loss of strength

- Use of prefabricated pre-insulated breathing wall, floor and roof panels

- Timber structure in place of concrete

- to avoid temporary formwork materials (plywood and softwood) used in formwork,

- potentially used a few times then thrown away to landfill as waste

Avoid:

- Wood substitutes: unless it is 100% recycled plastic

- Cradle to Cradle:

- avoid blending natural (wood fibre, wood flour) and technical (plastic binder)

- ingredients that cannot be separated at end of life,

- Proviso: unless the manufacturer:

- leases the product to the user,

- has a tack back scheme in place,

- is already recycling their own post consumer product

- Cradle to Cradle:

- Illegally forested timber

- (Use EUTR procedures)

- Non-sustainably managed forested timber

- Tropical Rainforest timbers,

- (there are probably other species which will do the job you need from nearer the site)

- Endangered species of timber,

- (Check the CITIES website)

- See GBE SPECIES TABLE

- Clear felled virgin forest timber

- Clear felled plantations if not replanted

- Indonesian Hardwood,

- most is reported to be illegally logged:

- destroys forests, communities and habitation

- Adhesives if fasteners will do the job required

- Burning timber off cuts on site

Minimise:

- PEFC certified forest timber, it does not address all the sustainability issues adequately, choose FSC first

- Synthetic adhesives if natural alternatives can do the job required

Substitute:

- Specify by performance requirement then the suppliers can choose available FSC species to do the job required and offer a range of colours close to your requirements

Health:

- Avoid formaldehyde adhesives in boards, compound or laminated sections See Z20

Wellbeing:

- Use planed and arrised softwood sections to minimize splinters whilst handling sections

Safety:

- Normal manual handling and mechanical handling safety measures

- Bulk timber is heavy and has momentum at the end of a sling from a crane

Precautionary principle:

- Use a sacrificial coatings during handling and installation

- Sand off all sacrificial coatings prior to hand over leaving in pristine condition

Resource Efficiency Issues:

Reduce:

- Use compound I section timbers, in place of solid sections:

- reduces use of timber, resource use reduction

- reduces fuel to transport

- easier to handle on site, often by just one person

Reclaim:

- All healthy timber that can be reused

Reuse:

- Second hand timber

- FSC now recognises reuse of timber

- Salvaged timber from existing building in:

- Softwood in stud walls, floors or roofs

- Floor boarding

- Doors, Windows

Recycle:

- Damaged untreated timber

- Make bat and bird boxes with offcuts

- Use as mulch in landscape

Recover:

- Nutrients from untreated timber by composting

- Energy from timber offcuts by saving in a biomass fuel store for use in the employer’s biomass boiler

Waste Issues:

Hazardous waste & Deleterious Substances:

- Preservative treated timber is hazardous

- Do not use preservative treated timber in bat and bird boxes

- Do not use preservative treated timber in childrens toys

- Do not use preservative treated timber in food growing planters, raised beds

- Preservative treated timber is potentially inert in landfill, but leaching may occur

Waste statistics

- 30 m tonnes (33% of 90 m. tonnes/year) of waste is offcuts (not all timber)

- 9.4 m tonnes (10.2% of 90 m. tonnes/year) of waste is Temporary works, Site hoardings and Formwork

Waste minimisation:

End of Life options:

- Dismantle for reuse (build it with the right fasteners)

- Choose durable species

Appropriateness:

- off site prefabrication to reduce waste:

- Use of prefabricated pre-insulated breathing wall, floor and roof panels

Competence:

- Reclaimed timber for reuse:

- check suitability for use in structural application

- there are 900 timber strength graders in UK

- some structural engineers will assess timbers for reuse

- Choose species with the right properties for the job

- Don’t choose your favorite coloured species for every application

- Don’t choose your favorite coloured species for external applications the colour will fade to silver or grey

Effectiveness:

- Steel sections can be smaller than timber to meet structural requirements

- If fire resistance is required steel sections get considerably bigger than timber

- Encasing steel or applying intumescent paint increases cost and environmental impact

- Timber sequesters carbon from the atmosphere so reduced atmospheric carbon now

- Timber buildings can be carbon negative

Yardstick:

- A standard is being developed to permit embodied carbon and sequestered carbon to be taken into account in Total Carbon calculations for buildings

Maintenance issue:

- Untreated unseasoned unfinished durable species timber need no decoration and need no maintenance of that decoration

Information sources:

- The Wood Explorer(USA, part free, mostly paid for access, via apps)

- A massive knowledge-based site featuring 1648 tree species.

- TRADA

- askTRADA

© GBE NGS ASWS BrianMurphy

aka BrianSpecMan

2008 – 25th July 2014 – 15th February 2018

G20 Carpentry/Timber Framing/First Fixing Checklist

Images:

© Structural Timber Association

© Solid Wood Solutions

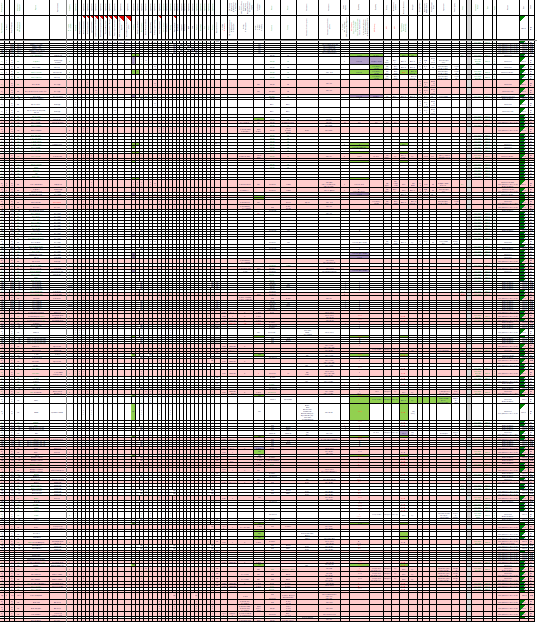

GBE DataSet

GBE Timber Species (Dataset) G#1371 N#1351

Avoid using the species in the pink rows

GBE CPD

If you wish to reproduce images, feel free, but please acknowledge the source.

© GBE NGS ASWS BrianMurphy

aka BrianSpecMan

25th July 2014 – 15th February 2018

G20 Carpentry/Timber Framing/First Fixing Checklist

See Also:

GBE JARGON BUSTER

- Term

GBE CPD

- Seminar

GBE CHECKLIST

- Trade

GBE LINKS

- TRADA

- askTRADA

GBE MANUFACTURERS

GBE PRODUCTS

GBE MATERIALS

GBE SYSTEMS

GBE ELEMENTAL ASSEMBLIES

GBE CALCULATOR

- Product

GBE DATA

GBE CAD

- 2D and 3D SketchUp Product files

- SketchUp files of Construction Sections

GBE GREEN BUILDING SPECIFICATION

GBE PROJECTS

© GBE NGS ASWS BrianMurphy

aka BrianSpecMan

25th July 2014 – 15th February 2018