Squashed Loft Insulation (Issue Paper)

Update No. 3

GBE > Encyclopaedia > Code > Issues > Topics > G#13919

Squashed Loft Insulation (Issue Paper)

About:

Slogan?

Squashed Loft Insulation > Cold Winters & Hot Summers > Lift Your Loft Stuff

Flattened Insulation > Cold & Hot rooms > Lift Your Loft Stuff

Lofts stuffed full? > Flat Insulation? > “Lift Your Loft Stuff”

Stuffed Loft > Squashed Insulation > Lift Your Loft Suff

Clumsy but the best I can do so far

#Hashtag

#LiftYourLoftStuff

Topic of this GBE Issue Paper: Squashed Loft Insulation

Update A03 8th December 2016

I hope you find this informative and useful.

Let me know.

If there are bits missing please point them out and I shall seek answers.

GBE Executive Summery

Squashed Loft Insulation is a significant subtopic of a future GBE Issue Paper: Performance Gap.

In Parker-Morris standard homes provided by Responsible Social Landlords, storage space can be dedicated walk-in wardrobe or stores or outdoor sheds.

In many cases wider rooms or corridors offer occupant choice and space for loose furniture wardrobes, but they may be occupied by other space consuming possessions, forcing reliance upon lofts for long-term storage.

In speculative developer homes the lack of designed in storage space forces occupants to rely on garages or lofts.

Storage space is needed for their many essential but infrequently used camping gear and Christmas decorations or now redundant possessions and belongings kept just in case.

Speculative housing developers do not want to provide storage platforms in lofts and the first thing occupant do once they have moved in is to open their loft hatch and store empty removal boxes and other possessions in their attic.

At all the DIY, renovation and homes shows there are raised storage/access systems displayed and sold.

Research shows a significant number of families regard the attic as vital storage space in any home.

80% of homes squash their insulation, some understanding the consequence, others not.

300-400 mm of attic insulation are now required by regulation or design standard and loft timbers are commonly 100 mm deep so possessions placed in lofts will squash insulation from 400 mm down to 100 mm.

Squashed Loft Insulation results in >200% greater heat loss than designed, contributing significantly to the Performance Gap.

Energy saving through thermal insulation is more and more vital for comfort, for fuel cost savings and for carbon reduction targets and squashed insulation reduces the ability to meet these aims.

Squashed Loft Insulation may be seen as an occupant created problem in reality there is no choice and housing providers need to address this failure from the outset.

Squashed Loft Insulation is also a significant subtopic of the GBE Issue Paper: Overheating.

In winter season most lofts are cold and this is a problem addressed by Building Regulation and Technical Standards

Cold lofts are often 0 degrees C or less, 20 C degrees colder than comfortable 20 degree C rooms

In summer season most lofts are hot but this issue is ignored by Regulations despite 20% of homes overheating.

Hot lofts often at 40 degrees C or more, are 20 C degrees warmer than comfortable 20 degrees C rooms.

Lofts heated by solar radiation warming the thin opaque roof surface warming the loft but also the top floor of accommodation, by conduction through the loft insulation.

Squashed loft insulation therefore also contributes to overheating in upper floors of homes and top floor flats.

Annotation:

- JB = Jargon Buster

- P = Problem(s).

- P/S = Problem(s) with Solution(s).

- S = Solution(s).

- S/P = Solution(s) with Problem(s)

GBE CPD: etc. hyper links will be connected when other pages and files are established in GBE website

Green text: updated or added since last issue

Highlighting major problem(s) that lead to significant overheating

Green text: new problem(s)

About the author

Brian Murphy is an architectural technician and architect by training, specification consultant by choice and environmentalist by action.

43 years in the industry, 33 years running specification consultancy, 17 years learning about environmental construction and disseminating it to many audiences.

Lecturer at Universities at BSc, PG Diploma and MSc courses, has created over 800 seminars on sustainable construction, procurement, specification and professional practice.

Founded NGS 2001 and launched GreenSpec www.greenspec.co.uk website 2003; 2009 posted 300 seminars and documents on www.scribed.com/brianspecman, they were opened 267,000 times (before the counter was reset and they started charging for reads).

2012 moved on to the next task and for the last two years developied a prototype website 1780 pages created out of 30,000 anticipated, 1.8m page views in 24 months and 2015 launched online Green Building Encyclopaedia https://greenbuildingencyclopaedia.uk to capture and disseminate everything, in the one stop shop that I proposed and everybody still keeps asking for, that should become the source of essential reading to be visited frequently.

This paper is also on GBE website where it is linked up with manufacturers and products.

Follow:

http://twitter.com/brianspecman

http://twitter.com/GBEGreenBuild

http://www.scribd.com/brianspecman

http://www.facebook.com/brianspecman

http://uk.linkedin.com/pub/brianspecman-murphy/9/494/492/

© GBE NGS ASWS BrianSpecMan aka Brian Murphy

Revisions:

| Revision | Comment | Author | Organisation | Date |

| A00 | CPD seminar for Architect and Specifiers | DR | LoftZone | 12/02/2016 |

| A01 | GBE LitAudit Literature Audit for LoftZone | BRM | GBE | |

| A01 | GBE LitEdit Literature Edit for LoftZone | BRM | GBE | |

| A02 | GBE copied CPD to word file to expand upon it for GBE Issue paper and GBE Defects page | BRM | GBE | 07/12/2016 |

| A03 | Copied this paper to GBE website Issue paper | BRM | GBE | 08/12/2016 |

Headlines

Loft insulation isn’t working in 80% of UK houses

- What can we do about it?

CPD Seminar

A one hour CPD Seminar for architecture and construction professionals is available

- Contact LoftZone

Order of content

- EST Energy Saving Trust guidance

- ‘In-Use Factors’ which diminish insulation performance

- Building Regulations, Technical Standards and voluntary schemes

- ZCH Zero Carbon Hub statistics on overheating

- DECC statistics on roof insulation

- NPL National Physics Laboratory research on insulation performance

- Carbon Trust surveys on loft usage

- RoSPA loft/ceiling accident statistics

- Alternative techniques to maximise insulation performance

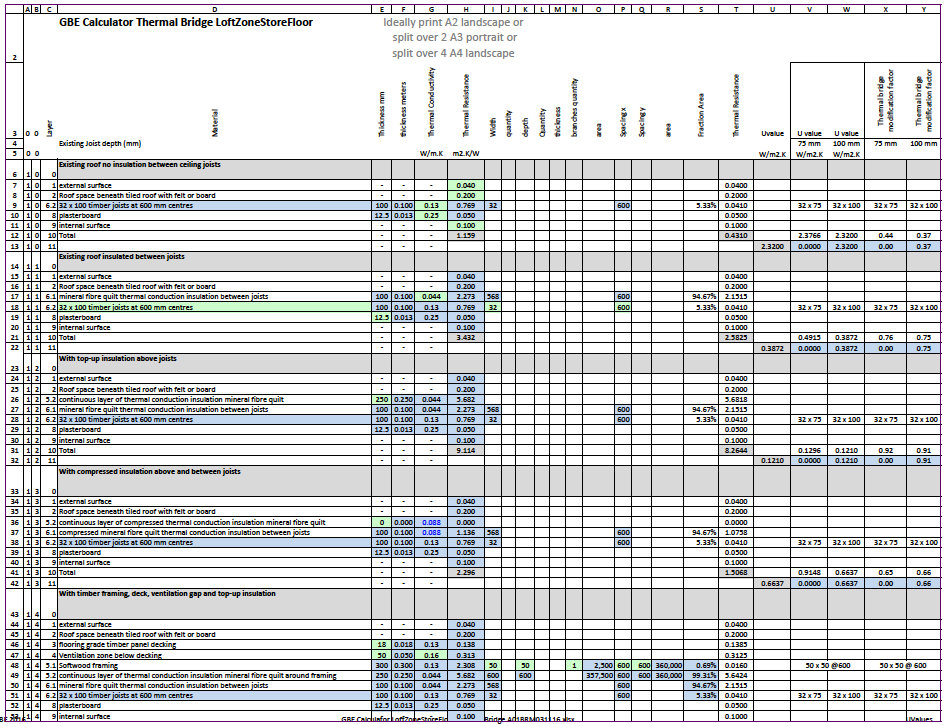

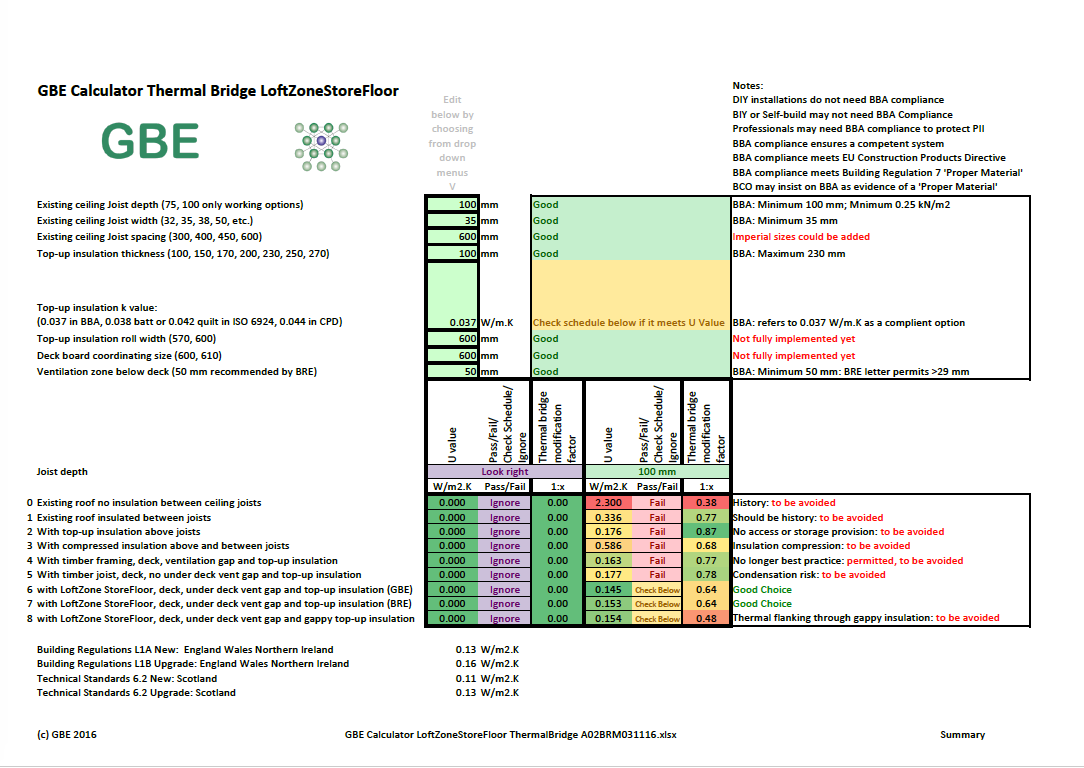

- GBE Calculator U Values & Thermal Bridge modification factors

- Test Questions and Answers

Loft insulation: why it’s needed

- On average, 25% of a building’s heat loss through its insulated external envelop is through the roof

- (source: Energy Savings Trust)

Loft insulation: Buildings Regulations & Technical Standards

| Type of application | Required U-value for the loft ceiling (W/m2.K | Required thickness of thermal conductivity insulation if laid at the ceiling of the loft |

| New build | U = 0.13 (EW&NI BRAD L1A)

U = 0.11 (Scotland STS 6.2) |

340mm

400mm |

| Retrofit | U = 0.16 (EW&NI BRAD L1B)

U = 0.13 (Scotland STS 6.2) |

270mm

340 mm |

Loft insulation: Other Voluntary Standards

| Type of application | Required U-value for the loft ceiling (W/m2.K) | Required thickness of thermal conductivity insulation if laid at the ceiling of the loft |

| New build Passivhaus | U = _____ | ___ mm |

| New build AECB Carbon lite | U = _____ | ___ mm |

| Retrofit EnerPHit | U = _____ | ___ mm |

| Retrofit AECB Carbon lite retrofit | U = _____ | ___ mm |

- NB: It should also be noted that mineral fibre keeps heat in during winter and summer and permits radiant heat in, in summer

Food for thought

- It should also be noted that:

- Mineral fibre and plastic thermal conductivity insulation

- Keep heat in during winter

- Do not readily let it out in summer (adding to overheating potential)

- And they do not keep radiant solar heat out in summer

- Leading to potential overheating (affecting 20% of housing (ZCH))

- Consider loft thermal conductivity insulation with the additional property of high decrement delay, including:

- Cellulose fibre flake (recycled newspaper)

- Easy installation around any framing

- Cork granules (easy installation) or boards

- Wood fibre batts or boards

- Other plant fibre insulation materials in various formats

- Cellulose fibre flake (recycled newspaper)

Food for thought

- Mineral fibre and plastics are good for stopping winter heat loss

- Mineral fibre and plastics do not stop solar heat gain through opaque building fabric

- UK Building Regulations do not address summer solar heat gain

- despite 20% of homes overheating in summer (ZCH)

- The subject of a separate CPD seminar by GBE

Thick top-up loft insulation: installation method

- Step 1: lay insulation between the joists (usually 75 or 100mm tall)

- Step 2: roll another layer at 90 degrees to the first layer, to give the total required thickness

Loft insulation: market penetration

- Of the 23 million domestic lofts in the UK:

- 15 million have >100mm of insulation

- (Source: DECC, 2016)

- The vast majority have been insulated using mineral fibre rolls, usually selected for cheapness and ease of installation

- Other materials are available:

- Cellulose fibre, wood fibre, cork, cotton, recycled denim,

- Foamed plastics, fibre plastics,

- Others formats include:

- Loose, blown or sprayed insulation

- Rigid board insulation

- Multifoils

So, once a loft is properly insulated, is everything okay?

- Unfortunately no, the performance is spoiled by:

- Significant ‘In-Use Factors’

- This means that loft thermal conductivity insulation does not work as well as it was meant to

- Assuming that the insulation has been fitted correctly:

- Without gaps and

- Permitting cross-ventilation at eaves

- Then ‘In-Use Factors’ come into play…

Some common In-Use Factors:

- Compression of the loft insulation

- g. by storage of belongings directly on insulation or on deck boarding

- Safe access deck boarding installed in the loft,

- Bearing on the ceiling joists

- Usually well below the required thickness of insulation

- Compressing the insulation above and between the joists

- Householder or maintenance contractor action,

- g. moving the insulation away to create safe access pathways and then not being able to replace it properly, or at all

- After becoming moist from condensation build up in the loft:

- Insulation deterioration

- Performance drop off

- Thermal bridging through the ceiling joists

Some less-common In-Use Factors:

- Vermin attack

- Wildlife inhabitation displacing or tunnelling through insulation

- Wind scour or wind washing at the eaves and along the top of the insulation, drawing heat out of the insulation surface

- Accumulation of dust and debris, especially after roofing work

- Water ingress through old and leaky roof coverings

The biggest ‘In-Use Factor’ is loft insulation compression

- Tests undertaken by the National Physical Laboratory showed:

- Compressing mineral fibre loft insulation:

- Affects the U value

- It is very significant

- Much greater than previously thought

- Compressing from 270mm to 100mm (4” ceiling joist height)

- U-value and heat loss increases by <200%

- Compression from 270mm to 75mm (3” ceiling joist height)

- U-value and heat loss increases by <240%

Loft insulation compression

- Squashed thickness: 100 mm

- Thermal resistance: 3.09 m2.K/W

- U value: 0.324 W/m2.K

- Difference in U values: 198%

(NB. Illustration is not recommended: the top-up insulation should run at 90 degrees to the ceiling joist zone insulation to avoid thermal bridges and thermal bypass)

- Recommended thickness: 270 mm

- Thermal resistance: 6.11 m2.K/W

- U value: 0.164 W/m2.K

This loft may look tidy,

- But from a thermal conductivity insulation perspective, it is very poor (at least in the central area)

- The insulation is either only 100 mm (up to joist height)

- Or the insulation has been squashed down to 100 mm

Causes of thermal conductivity insulation compression

- Storage of belongings:

- directly on the insulation

- or on decking on top of the insulation

Loft ceiling light storage loadings

- Building Regulations Approved Document A Table 4 and

- BS 5268:Part 3 for modern trussed rafter roofs

- Require the loft ceiling to support:

- 25 kN/m2 distributed imposed load (for storage)

- (1/8th of the loading for a domestic floor)

- 90 kN concentrated point load (for a person accessing loft)

- 25 kN/m2 distributed imposed load (for storage)

- Traditional insitu cut timber roofs are often much stronger than trussed rafter roofs

- Many building owners and occupiers want to use their loft for storage

Loft storage is important

- 6000 survey respondents:

- 78% say loft storage is important or essential

- 82% use their lofts for storage

- Of those, 78% say theirs is more than half full

- Only 26% know that squashing insulation is bad for it

- Source: Carbon Trust survey

- Biggest ever UK survey of loft users

Safety in lofts is an issue:

- 200 hospital visits each year in the UK owing to:

- falls from lofts

- falls through loft ceilings

- (source: RoSPA)

- Architects and builders have a requirement to design-in safe maintenance under CDM 2015

- Landlords have a ‘Duty of Care’ to their maintenance staff

Access is required to services:

- Cold water storage tank, ball valve, water supply and delivery pipes, insulation and overflow pipe

- Boiler top-up tank, ball valve, water supply and delivery pipes, insulation and overflow pipe

- Boiler fuel and power supply, flues, pipes and insulation

- Communal or District heating flow and return pipes and insulation if fitted

- Hot water cylinder or solar cylinder, ball valve, water supply, overflow and delivery pipes, and insulation

- Solar thermal panel expansion tank, pipes and insulation

- Solar PV inverter and cables

- Power Shower Pumps

- Extractor fans and ducts

- MVHR Mechanical Ventilation with Heat Recovery ducting

- Power and data cables and conduit

- Pipe work and insulation

- TV aerial, satellite dish, cable box and cables

- Domestic sprinkler system pipework and insulation

- Smoke detectors and cables

- Warden Call systems

- Ceiling mounted down lighters

- Ceiling mounted fans

- Ceiling mounted air conditioning units

Safe access platforms can be the cause of top-up insulation removal or compression

It all adds up….

- 25-30% (2005) of UK energy demands are from domestic property

- Heat lost through Loft: 25%

- Squashed insulation 50% performance

- 80% of Houses Squash Insulation

- Ofgem estimates that In-Use Factors reduce the effectiveness of UK-wide loft insulation by 29% (2013)

- Ofgem Energy Company Obligation measures

So what are the alternatives?

- Raising timber panel decking above existing joists with softwood framing or joists

- Decking on top of rigid foamed-plastic boards

- Proprietary supports and decking systems

Raising decking above existing joists with softwood joists and timber panel decking?

- Raising timber panel decking on new softwood framing or joists is no longer good practice

- This used to be common practice when thermal conductivity insulation thickness requirements were low

- But the extra timber is:

- heavy and awkward to get in and fit in a confined space

- Also acts as a thermal bridge through the insulation

- Linear (if on top of joists) or Point (if laid at right angles to existing joists)

- Psi values for the thermal bridges have to be allowed for in the U-value calculation for the roof under Building Regulations or Technical Standards

- This will require an increase in thermal conductivity insulation thickness to compensate

- If there is no room in the loft location

- It will be needed elsewhere

- Not forgetting to put back in place any existing top-up thermal conductivity insulation before decking over

- Taking care to fit gap-free insulation around framing or joists

Decking on to rigid foamed plastic insulation?

Risk associated with decking on top of rigid foamed-plastics insulation

- Foamed Plastics insulation are not normally moisture permeable so vapour barriers are essential but difficult to add to existing ceilings

- The lack of a vapour barrier can cause interstitial or surface condensation, as moist air passing through the ceiling insulation it will cool and may condense on the underside of the deck board

- For conventional pitched roof cross-ventilation it is recommended that there is at least a 50 mm air gap at the eaves

- This cross ventilation gap should be continued between the top of the insulation and the underside of the decking board (source: BRE)

- Plastic insulation must not be allowed to touch plastic conduit or plastic sheathing to electrical cables

- Polymer migration may modify the performance of both plastics

- Plastics can dissolve away

- Polystyrene rigid foamed-plastic

- Polyurethane spray foam insulation

- Polymer migration may modify the performance of both plastics

- Large sections of rigid insulation/decking are also hard to get through the loft hatch and fit within a confined loft space

New raised loft decking systems

- There are a number of new products and systems on the market

- Only one system has been approved by BBA for use in construction:

- It is strong enough to withstand the required loading

- It is tall enough to meet modern insulation thicknesses

- Without creating a significant thermal bridge through the insulation

- It has a ventilation gap to avoid surface or interstitial condensation.

- That system is LoftZone StoreFloor

LoftZone StoreFloor: plastic supports and metal beams to raise timber panel decking

Reduced Ventilation Gap

- 50 mm pitched roof cross ventilation is default practice to reduce risk of interstitial condensation, BR, BRE and BBA recommend it

- BBA were asked ask to carry out hygro-thermal moisture movement and thermal bridge analysis of LoftZone StoreFloor details

- They concluded 29 mm ventilation gap would was unlikely to cause interstitial condensation

Thermal bridge through supports?

- BRE Buildings Research Establishment

- calculated the thermal conductivity through the plastic supports to be negligible

- they need not be considered in U-value calculations

Thermal bridge through supports?

GBE Calculator LoftZone StoreFloor

LoftZone StoreFloor installations

LoftZone StoreFloor installations

- Also used for safe access walkways in schools

Summary

- Loft insulation ‘In-Use Factors’, in particular, compression are a major issue

- Significant numbers of houses are affected

- Adding considerably to UK energy and fuel demands and carbon outputs of UK housing

- Most traditional means of solving the need for storage space, safe access walkways are no longer good practice

- The LoftZone StoreFloor is the only product for this purpose that has been approved by BBA for use in construction.

Test Questions:

- What percentage of households use their loft for storage? (35%, 50%, 82%)

- If loft insulation is compressed from 270 mm to 100 mm joist height, by how much does the U-value change? (It halves, it doubles, it stays the same)

- What is the gap recommended by BRE between the top of the insulation and the bottom of the deck, to prevent surface condensation on the underside of the deck boards? (35 mm, 50 mm, 82 mm).

- What does Ofgem consider the total reduction in the effectiveness of UK loft insulation owing to In-Use Factors? (35%, 50%, 82%)

- What is the requirement for the loading of the bottom chord of trussed rafter roofs?

(0.25 kN/m2 distributed imposed load plus 0.90 kN concentrated point load

0.50 kN/m2 distributed imposed load plus 0.90 kN concentrated point load

0.82 kN/m2 distributed imposed load plus 0.90 kN concentrated point load) - Under which regulations are architects and builders required to design in safe maintenance access? (Part L1A, STS 6.2, Working at Height Regulations, CDM 2015)

Test Answers:

- 82% of households use their lofts for storage

- U value doubles when insulation compressed 270 to 100 mm

- 50 mm cross-ventilation gap is recommended by BRE

- Ofgem consider ‘In-use factors’ reduce UK insulation effectiveness by 35%

- 0.25 kN/m2 distributed imposed load plus 0.90 kN concentrated point load

- CDM 2015 requires safe maintenance access to be designed in

© LoftZone original text 12/02/12

© updated by GBE Green Building Encyclopaedia 2016

© GBE NBS ASWS BrianSpecMan aka Brian Murphy

8th December 2016

Squashed Loft Insulation (Issue Paper)

Images:

LoftZone Logo

© GBE NBS ASWS BrianSpecMan aka Brian Murphy

8th December 2016

GBE Issue Paper Squashed Loft Insulation

See Also:

GBE Issue Papers

- Overheating (Issue Paper) G#145

- Squashed Loft Insulation G#13919

GBE Jargon Buster

- Theme:

- Thermal Insulation

- Squashed Loft Insulation

- Words and Phrases

- Conductivity Thermal Insulation

- Radiation Thermal Insulation

- Thermal Break (Jargon Buster) G#9357

- Thermal Bridge (Jargon Buster) G#9351

- Wind Wash (Jargon Buster) G#14021

GBE CPD

- Topic (cut down version of this paper illustrated)

- LoftZone-cpd-training PDF Show

GBE Library

- List of related documents by authoritative bodies

- ZCH

- DECC

- NHBC

GBE Links

GBE Solution Providers

- Eco Answers Ltd t/a LoftZone G#13890

GBE Solutions

- StoreFloor G#13287

© GBE NBS ASWS BrianSpecMan aka Brian Murphy

8th December 2016 – 28th December 2016