D11 Soil Stabilisation Checklist

GBE > Encyclopaedia > Code > Checklist > G#1587 N#1519

D11 Soil Stabilisation Checklist

Index:

Problems:

- Arisings from service trenches excavated to exposed existing underground services is often condemned to landfill

- Special ingredients have been introduced to the market to allow service trench arisings to be relaid in the same service trench

- At least one American product used by their military and globally in civil engineering, uses hazardous soluble chromium, in a trench that is likely to become a waterway for ground water, with very high potential to poison ground water which may potentially reach sources of drinking water

- High ground water table or rainwater saturating subsoil and site vehicle movements will churn up a site and turn it into a vehicle trap and a no go area or result in mud puddles to splash new materials rendering them unacceptable for use

- Removal of subsoil from site to landfill

- Decreasing landfill capacity

- Increasing landfill tax and landfill gate prices

- Importing demolition rubble or virgin stone for hardcore and sub-bases

Misunderstandings:

- None identified so far

Solutions:

- By adding lime, lime and cement or cement to saturated subsoil will use the excess water for hydration and turn the subsoil into a weak concrete like material, creating a firm dry base sufficient to provide a firm surface for vehicles or equivalent to a consolidated hardcore base for laying concrete floors or sub base for pavement, roads and runways

- Excess subsoil can be used imaginatively in landscape modelling

- Excess subsoil can be turned into topsoil by adding compost See D12

Consider:

- Dynamic compaction or consolidation allows improvement of sub-soil loadbearing capacity without the use of foundations

- Dynamic compaction or consolidation and vibration techniques with or without the addition of stone or recycled concrete aggregate into piling hole can provide piled construction without the piles, i.e. no new concrete

- Aggregate replacement See E10

- Cement Substitution:

- Lime in preference to lime-cement

- Using lime allows the process to be undone,

- Lime-cement in preference to cement

- cement is more permanent

- OPC replacement with GGBS (but expect a slower set)

- Blended GGBS with OPC (to achieve normal setting times)

Avoid:

- Soluble chromium in special ingredients aimed to permit service trench arisings being reuse in the same trench

- Injecting cement in grout-form to stabilise ground

- Excavation of subsoil

- Disposal of subsoil, reuse on site where possible

Minimise:

- Use of OPC Cement and OPC Concrete See E10

Substitute:

- GGBS for OPC See E10

Health:

- Lime, Cement and Concrete are alkali and corrosive to skin

Wellbeing:

- Use Barrier creams before work in site to defend against lime, cement or concrete burns

Safety:

- Wear protective goggles, gloves and knee pads

Precautionary principle:

- Cements are a very fine powder, avoid breathing them in

- What they can do to the skin can be done internally

Resource Efficiency Issues:

Reduce:

- Removal of subsoil from a site

Reclaim:

- None identified

Reuse:

- None identified

Recycle:

- Inert concrete demolition materials can be recycled on site:

- added to concrete mix

- Inert concrete or masonry demolition materials can be recycled on site:

- used as consolidated hardcore or sub-base

- create a piling mat

Recover:

- None identified

Waste Issues:

- Hazardous waste & Deleterious Substances

- Waste statistics

- Waste minimisation

- End of Life options

Appropriateness:

- None identified

Competence:

- Always use materials complying with BSI Kitemark or MOT accreditation

Effectiveness:

- Keeping existing materials onsite and improving them insitu is effective since it avoids the work transport and emissions removing them, avoids occupying landfill and avoids having to import materials to fill the gap created by their removal

Yardstick:

- Always use materials complying with BSI Kitemark or MOT accreditation

Maintenance issue:

- Site consolidation or compaction are inaccessible once covered over by building

Information sources

- AggRegain

- WRAP

© CCPI 1987 & 1998

© NBS 2013

© GBE NGS ASWS Brian Murphy aka BrianSpecMan *

21st July 2014 – 27th August 2019

D11 Soil Stabilisation Checklist

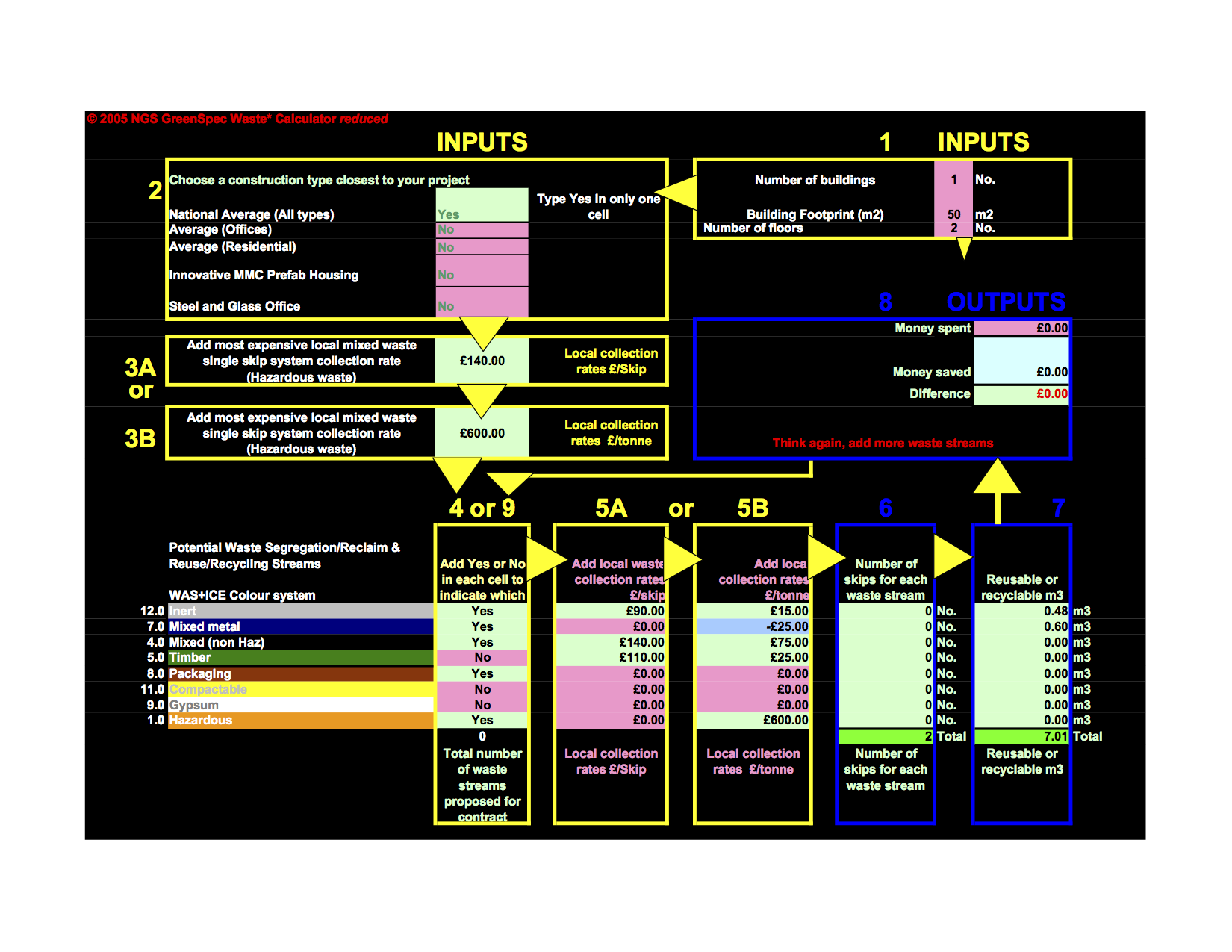

Images:

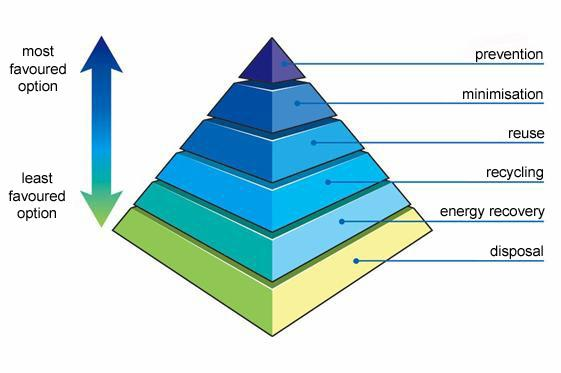

Waste Hierarchy (pre-2011)

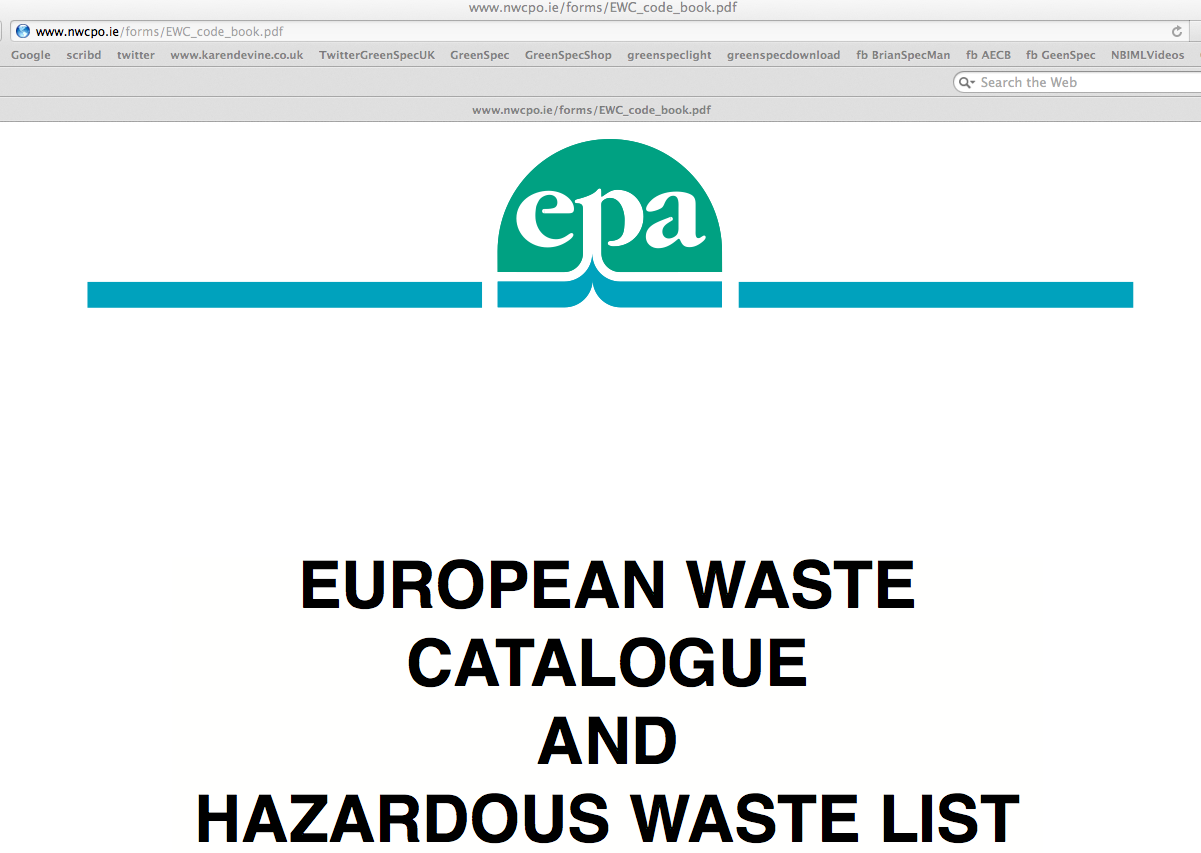

European Waste Catalogue (EWC)

GBE CPD

© GBE NGS ASWS Brian Murphy aka BrianSpecMan *

21st July 2014 – 27th August 2019

D11 Soil Stabilisation Checklist

See Also:

GBE JARGON BUSTER

Theme

Initials, Abbreviations, Acronyms

- EWC

- NISP

- SWMP

- WRAP

Words and phrases

- Active Waste

- BioEngineering

- BioRemediation

- Clean Subsoil

- Compost

- European Waste Catalogue (EWC)

- Green Waste

- Inert Waste

- Loam

- National Industry Symbiosis Programme (NISP)

- Site Waste Management Plan (SWMP)

- Site Remediation

- Soil Improvement

- Subsoil

- Surveying

- Surveyors

- Topsoil

- 1286: Waste

- 1287: Waste Broker

- Waste Calculator

- 1290: Waste Champion

- 1289: WasteCost®lite

- 1288: Waste Hierarchy

- 1269: Waste Stream

- Waste Transfer Notes (WTN)

- Waste Transfer Stations

- 1292: Waste Types

- 1060: Waste & Resource Action Programme (WRAP)

GBE DISCIPLINES

© GBE NGS ASWS Brian Murphy aka BrianSpecMan *

21st July 2014 – 27th August 2019