GBE Loft Insulation Defects

GBE > Encyclopaedia > Code > Defects > G#14166

GBE Loft Insulation Defects

About:

GBE Defects:

Subject: Loft insulation

- Loft Insulation is simple so why and how does is it contribute to the ‘Performance Gap’?

Definition of Performance Gap

- See GBE Issue Paper: Performance Gap

What needs insulating?

- Government insulation programmes seem to only know about a few things:

- Lofts

- Cavity walls

- Hard to treat Solid Walls

What is missing?

- Suspended Ground floor

- Party Cavity Walls

- Not-flat ceiling

- Roof triangles

Definition of Loft

- Government insulation programme’s Insulation installers are only geared up for

- The flat ceiling under pitched roof at the top of bungalows

- The flat ceiling under pitched roof at the top of two storey houses

- The flat ceiling under pitched roof at the top of multiple storey flats or apartments

What are the missed opportunities

- Chalet Bungalows

- Chalet Bungalows were popular pre and up to 1960’s

- Mansard roofs

- Mansard roof are often dictated by developed hungry for more floor area and T&C Planning control requiring extra floors above parapets to be stepped back and less visible from the street

- Room in Roof

- Have become popular with speculative developed to maximize the habitable room density on sites

What is different about these?

- Eaves and ridge triangles

- Sloping wall lining

- Ceilings that follow the slope of the roof

How are these different?

- They often do not have access hatches to all areas

- They are often inaccessible or difficult to work in due to small dimensions

- They are technical difficult or fiddly to retrofit

- They need more care than skill, the industry is equipped with skill and not permitted time to care

- Self-builders may not have skill but will care and often do a better job than constructors

- They are time consuming and not profitable for ‘flat ceiling under pitched roof’ contractors

- They are best carried out by removing the roof covering, insulating and replacing the roof covering

- Metal roof coverings need specialist skilled and expensive tradesmen to do this

- Tiled and slated roofs need some skills and lots of labour

- They have a large overhead cost to address

Does age come into it?

- Pre-1960’s insulation was not required by by-laws or regulations

- Grant supported projects in the 1970’s had their existing 0 mm or 50 mm of insulation increased to 100 mm or by 100 mm or more current requirement at the time

- Pre-1980’s insulation was not required by London by-laws

- More recent funding or regulation requires insulation to be topped up to current standards

- Today buildings are insulated to 300-400 mm overall thickness (based on mineral wool k value)

Definition of Insulation

- Government insulation programmes are only geared up for

- Cheap insulation (materials with the biggest market shares)

- Approved insulation (Approval that big market share manufacturers can afford)

- Fast and Simple insulation (that is still easy to get wrong)

- Contractor led specification driven by time and cost (not by all the performance requirements)

- Contractor that do not understand building performance and building failures (or do not have time to care)

- GBE are not sure many UK RIBA accredited course trained Architects understand building performance either

- Post 2020 we anticipate that getting better, slowly

- Government insulation programmes Insulation installers are only geared up for

- Glass mineral wool conductivity thermal insulation

- Rock mineral wool conductivity thermal insulation

- Glass or Stone wool or foamed plastic insulation for external insulated render

- Glass or Stone wool or foamed plastic insulation for internal insulated plasterboard

- Stone wool blown fibre or injected foamed plastic insulation into cavity walls

What is wrong with these insulation types?

- These insulation materials have been middle of the road (MOR) performance

- By todays standards with Aerogels and VIPs they are now amongst the worst performers

- But this assumes the k value (conduction) is the only performance criteria

- Conventional insulation material marketing reinforces the idea that k value is the only criteria

- For Building Regulations and Technical Standards k value is the only criteria

What other criteria should be considered with any thermal insulation?

- Convection

- Wind washing

- Thermal bypass

- Thermal flanking

- Air and wind tightness

- Radiation

- Thermal mass

- Density

- Specific heat capacity

- Decrement delay

- Surface Properties

- Low emissivity

- High reflection

- Conduction (already mentioned in previous item)

- Thermal bridging

- Moisture management

- Vapour open v vapour closed

- Hygro-thermal moisture movement

- Hygro-scopicity

- Moisture management

- Moisture Transport

- Water tolerance

- Wicking

- Capillary Action

- Hydro-phobic

- Frost resistance

- Fire performance

- Toxic Fumes

- Acoustic Performance

- Acoustic Barrier

- Acoustic Absorption

- Biodiversity Action

- Nesting

- Roosting

- Climate Change

- Embodied Energy

- Embodied Carbon

- Sequestered Carbon

- Global Warming Potential

- Green House Potential

- Alternative ways of insulating a roof

- Ageing

- Surface condition

- Closed pores/cells surface

- Open pores/fibres/cells surface

- Faced surface

- Low emissivity surface

- Installation methods

- Formless materials

- Methods of application

- Poured in

- Blown In

- Injected In

- Sprayed In

- Formed materials

- Oversized

- Accuracy of fit

- Gappy Insulation

- Jigsaw puzzle

- Flexible materials

- Squeezable

- Compressions

- Squashed Insulation

- Resilience

- Loft retention

- Compliance

- Congestion

- Competing for space with services

- Separation of insulation from services

- Formless materials

How does Loft insulation fail?

Problem: Wrong materials

- Good k value thermal insulation reduces heat loss by conduction in winter

- Good k value thermal insulation does nothing to stop solar radiation heat gains in summer

- Good k value thermal insulation reduces heat loss by conduction in summer

- Solar heat gains in summer gets in with ease but cannot get out, leading to overheating

- These include: stone, glass and slag mineral wools at normal densities,

- These include: Plastics: injected, sprayed, foamed, expanded or extruded and recycled

- These include: Structural Insulated Panel Systems (SIPS), Metal faced insulated core cladding panels

- These include: Vacuum Insulated Panel (VIP)

Solution: Right materials

- All roofs that can see the sun (most of them)

- Need to be insulated to protect from solar radiation heat gains

- This needs materials with high density, high specific heat capacity, low thermal conductivity

- These include: plant and tree based materials: e.g. Cork, Hemp, Wood fibre,

- These include: Expanded mineral: e.g. Cellular glass

- This includes: e.g. recycled newspaper cellulose fibre flake

Problem: Installation

- Undersized insulation placed between framing leaves gaps between insulation and framing

- Insulation spaced apart leaves gaps between rolls of insulation

- Over-sized spacing of framing creates gaps that standard sized insulation cannot fill without leaving gaps

- Lack of care in closing gaps in between insulation

- Gaps created permit heat loss by thermal by-pass or thermal flanking

Solution: Installation

- This can be solved by rolling out the insulation at right angles to framing allowing unrestricted placing of the insulation, close connection between rolls and between rolls and frames

- But: This may be more labour intensive and prone to inaccuracy in sizing of cuts leaving more gaps

Problem: Retrofitting

Problem: Existing insulation

- Old insulation may be non-existent

- Old insulation may be in sufficient thickness to fill the framing zone it occupies

- Old insulation may be wrongly sized or badly fitted

- Old insulation may have degraded by moisture, dust, age

- Old insulation may have lost its performance characteristics

- Old insulation may have been inhabited by nature and may be full of tunnels from the eaves inwards

Solution: Existing insulation

- The insulation layer nearest the ceiling needs to perform at its best

- It may make sense to remove, bag-up and dispose of degraded, dust filled, holey or damp insulation

- Re-insulate the framing zone with pristine new appropriate-sized, well-fitted insulation of the correct thickness

Problem: Water tank platform Insulation

- Insulation missing under water tank platforms is normal practice, to warm the water in the tank to prevent freezing.

- But insulation missing at the perimeter of tank platform just lets the heat dissipate uncontrollably into the cross-ventilated cold-roof

Solution: Water tank platform Insulation

- Insulation squeezed between the ceiling and the bottom of the water tank platform at the perimeter of the platform will close the air gap and trap the heat below the tank and not leaked out to the cross-ventilated loft

- Top up insulation may close the gap around the perimeter of the water tank platform

- An insulated enclosure to the water tanks and platform that goes down to the ceiling joists will close the gap

Problem: Adding top-up insulation

- Adding a second layer in any construction offers opportunities for loss of performance if joints in each layer correspond and potentially let the loss of performance affect the total thickness

- A gap between insulation in any layer will permit heat loss

- The thicker the total insulation thickness the greater the % of heat loss through the gaps

Solution: Adding Top-up insulation

- Second layers should be staggered in 1 or 2 directions compared to the first layer or better still turned through 90 degrees to the first layer and staggered in 1 or two directions

- Insulate by using poured-in/blown-in insulation that fills every gap, at such a density that they have good airtightness and have decrement delay as well as k value and hygroscopicity.

GBE Defects:

- Attic cistern thermal insulation enclosure G#1041 N#1058

Problem: In-use:

Problem: Wind washing at eaves

- All cold roofs require cross ventilation to ensure the risks of condensation is minimized

- The eaves and ridge needs ventilation slots to permit the cross-ventilation

- In windy conditions the cross-ventilation washes across the thermal insulation at the eaves

- Open pored, open celled or open fibred low density insulation materials will have the heat drawn out of their open surface and blown away

- Closed surface insulation can lose heat by emissivity and wind-wash will cool the air at the surface to encourage more heat to the surface by conduction

Solution: Wind washing at eaves

- Wind baffles placed to maintain the 50 mm air-gap made of dense board like hardboard or breathing sheathing board offer resistance to wind-wash

- Paper-faced, Foil-faced insulation, closed cell insulation offer some resistance to wind-wash

- Dense insulation materials offer some resistance to wind-wash (but dense insulation usually means a poor k-value but improved decrement delay)

- Bagged insulation: are being promoted for insulation at the eaves to overcome wind-wash

- But: if the bag is a vapour barrier on both sides of the insulation that is not ideal

- But: if the bag is a breather membrane on both sides that is not ideal if the insulation is not hygro-scopic

- However if the bag is vapour barrier on one side and breather membrane on the other, this must be installed vapour barrier down and breather membrane up or that could be a disaster

Problem: Cross ventilation

- Heat emitted from the loft insulation surface, convected up and cross-ventilated to blow it away

Solution: Cross ventilation

- Low emissivity foil-faced insulation can offer some resistance to emissivity losses

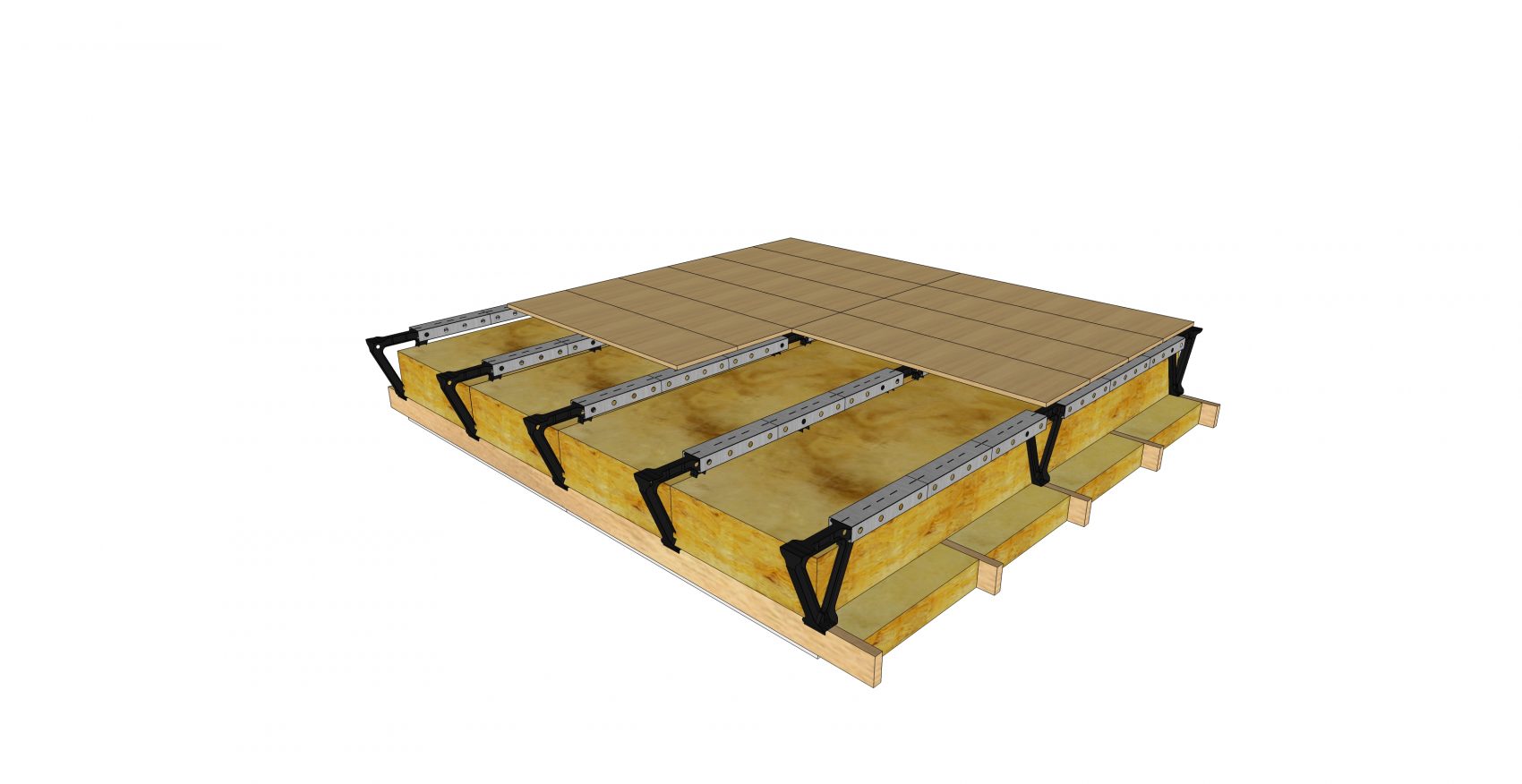

Problem: Squashed Insulation

- Storage space is needed by house occupiers for their many essential but infrequently used camping gear and Christmas decorations or now redundant possessions and belongings kept just in case.

- 300-400 mm of insulation between and above 100 mm ceiling joists means insulation will be compressed by their possessions and belongings

- Compression down to 33% to 25% of their thickness at least doubles the U value and doubles the heat lost in winter

- Hot lofts caused by solar radiation on to the roof coverings, conducting through the roof coverings warming the loft air to >40 degrees C

- Heat conducts down through the unsquashed and more easily through the squashed insulation and heats up the top floor landing and bedrooms in summer

Solution: Squashed Insulation

- Raised storage/access platforms enable the possessions and belongings to be stored in the loft without impairing the loft insulation’s ability to do its job

Solution Providers:

- Eco Answers Ltd t/a LoftZone G#13890

Solution:

- StoreFloor G#13287

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

20th December 2016 – 16th May 2021

GBE Loft Insulation Defects

See Also:

GBE Calculators

- GBE Green Building (Calculator) G#38491

GBE Defects

- Attic cistern thermal insulation enclosure (Defect) G#1041 N#1058

- Loft Insulation (Defect) G#14166 (This Page)

GBE CPD

- GBE will turn this into a CPD PPTX and PDF is asked.

- But here is a Word File and a PDF:

- GBE Defects Loft Insulation A02 BRM 211216

GBE Checklist

- K43 Raised Storage Access Systems (Checklist) G#13934

GBE Question & Answer

- Overlaying Loft Insulation (Q+A) G#38593

- Overlaying Existing Attic Thermal Insulation

- Reusing cavity wall insulation as Attic insulation

GBE Issue Papers

- Overheating (Issue Papers) G#145

- Squashed Loft Insulation (Issue Papers) G#13919

- Performance Gap

GBE Manufacturers

- Eco Answers Ltd t/a LoftZone G#13890

GBE Suppliers

- Eco Answers Ltd t/a LoftZone G#13890

GBE Installers

- Installer network via Eco Answers Ltd t/a LoftZone G#13890

GBE Products

- StoreFloor (Product) G#13287

GBE Accessories

GBE Systems

LoftZone StoreFloor #LiftYourLoftStuff

- StoreFloor G#13287

GBE Jargon Buster

- Thermal Barrier

- Thermal Break (Jargon Buster) G#9357

- Thermal Bridge (Jargon Buster) G#9351

- Wind Wash (Jargon Buster) G#14021

GBE Files

GBE Robust Specification

- GBS K43 120A StoreFloor (RSW) G#14031

GBE Shop

- GBS K43 120A StoreFloor (Shop) G#14037

GBE Slogan

- Knowledge-Gap, Skills-Gap, Care-Gap,Performance-Gap

- Build-Light, Insulate-Right, Solar-Tight (Slogan) G#2272

- Stuffed-Loft, Squashed-Insulation, Lift-Your-Loft-Stuff (Slogan) G#13957

- Build-Tight, Ventilate-Right

- Don’t Cook Your Client

- Fabric First Materials First Performance First (Slogan) G#17243

GBE Past Events

- Designing to Optimise Energy Use and Comfort in Major Home Extensions (Past Event) G#12200

GBE #Hashtag

- #Knowledge>Skills>Care>PerformanceGap

- #BuildLightInsulateRightSolarTight

- #LiftYourLoftStuff

- #BuildTightVentilateRight

- #DontCookYourClient

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

20th December 2016 – 16th May 2021

GBE Loft Insulation (Defects) G#14166

CAD 3D BIM Files (Collaborate)

Images:

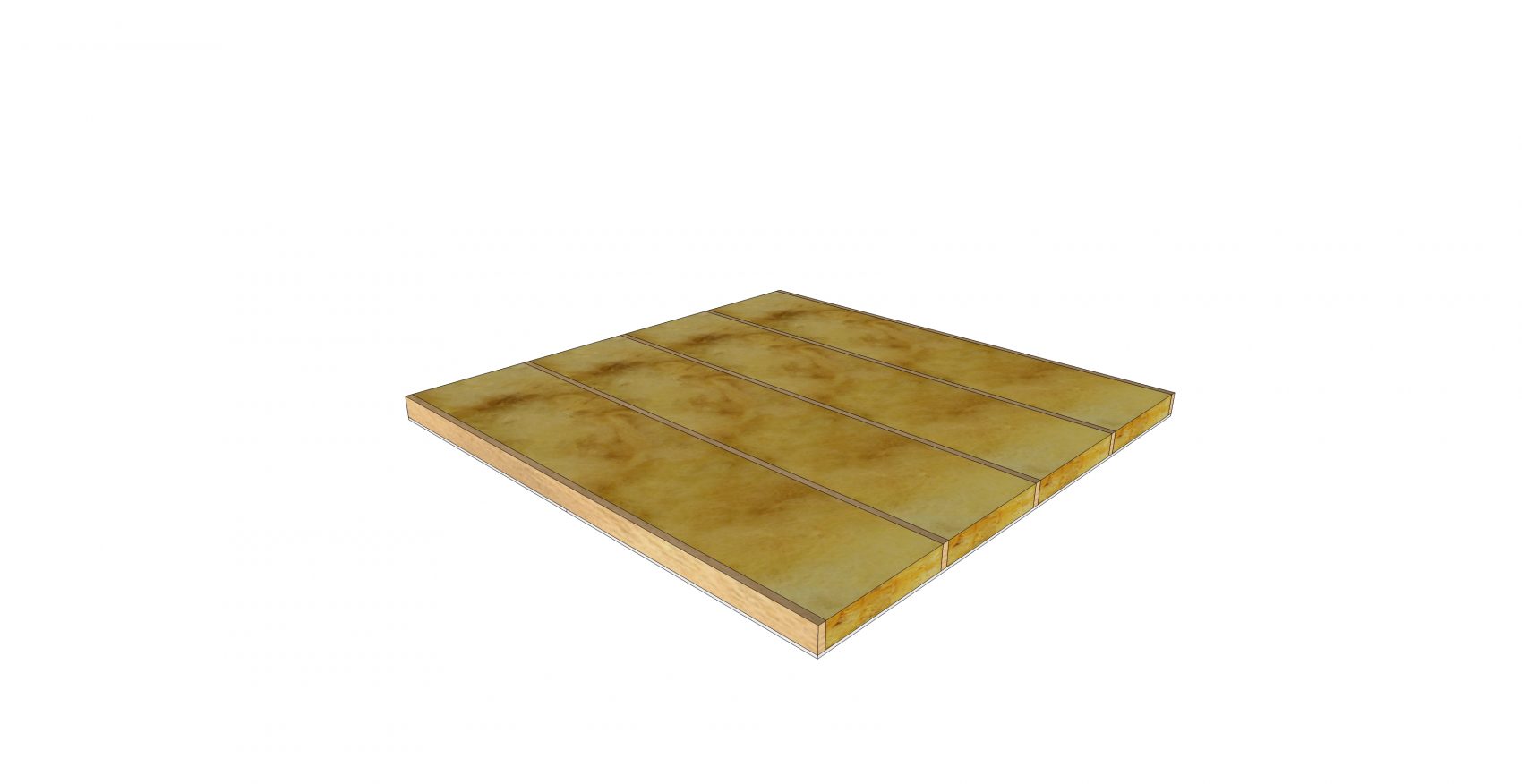

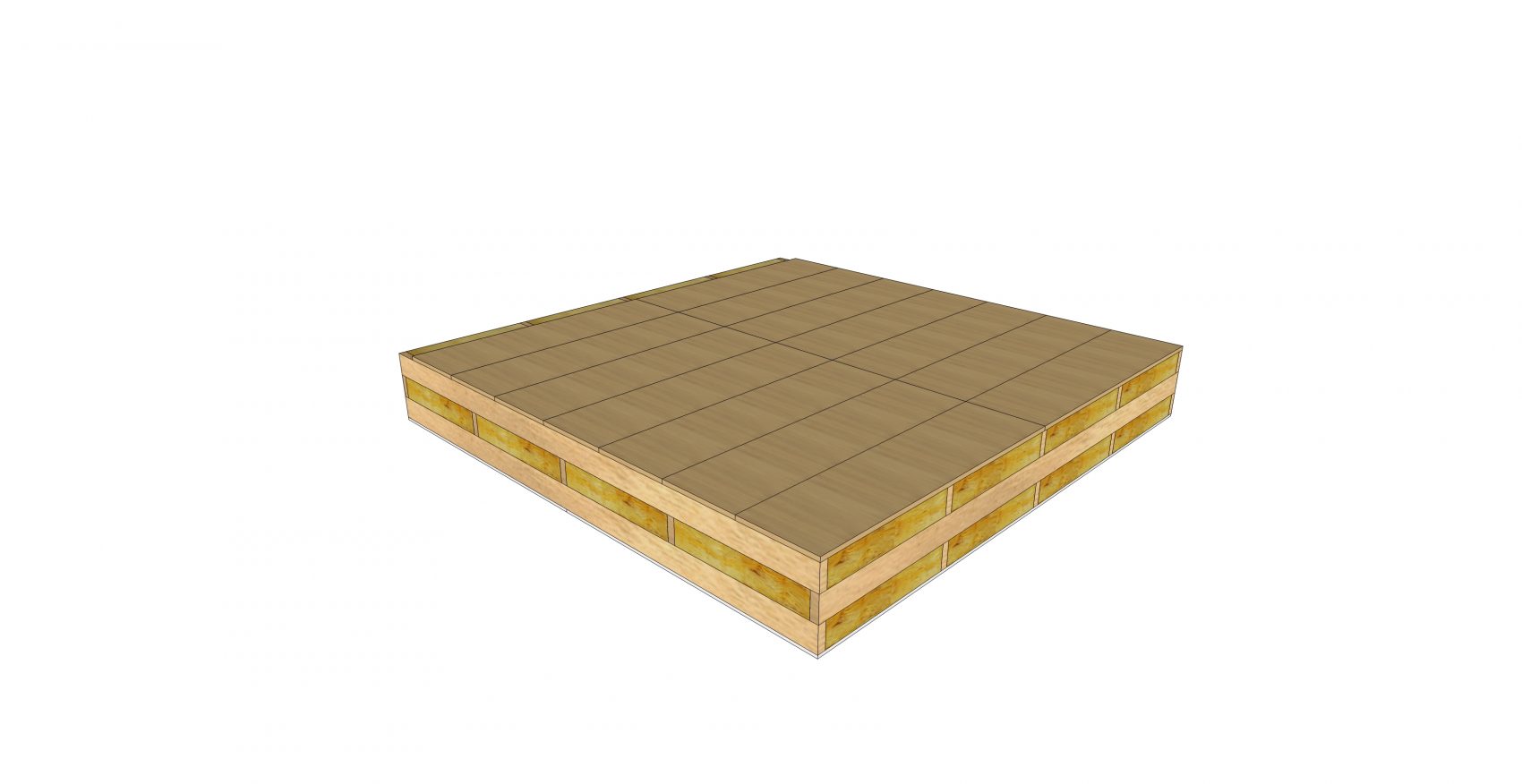

Uninsulated Loft Ceiling

Inadequately insulated Loft Ceiling (Insulation is depth of ceiling joists)

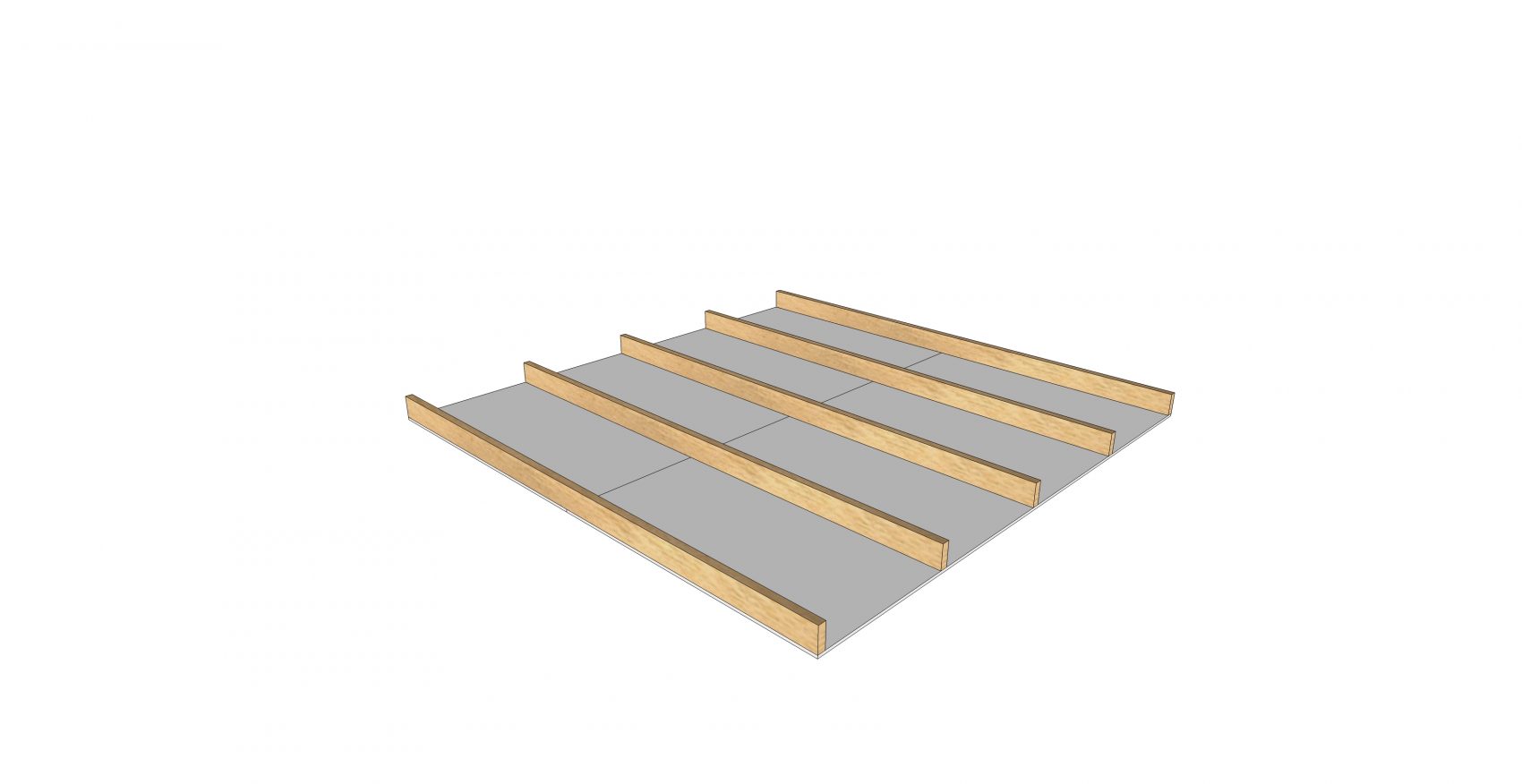

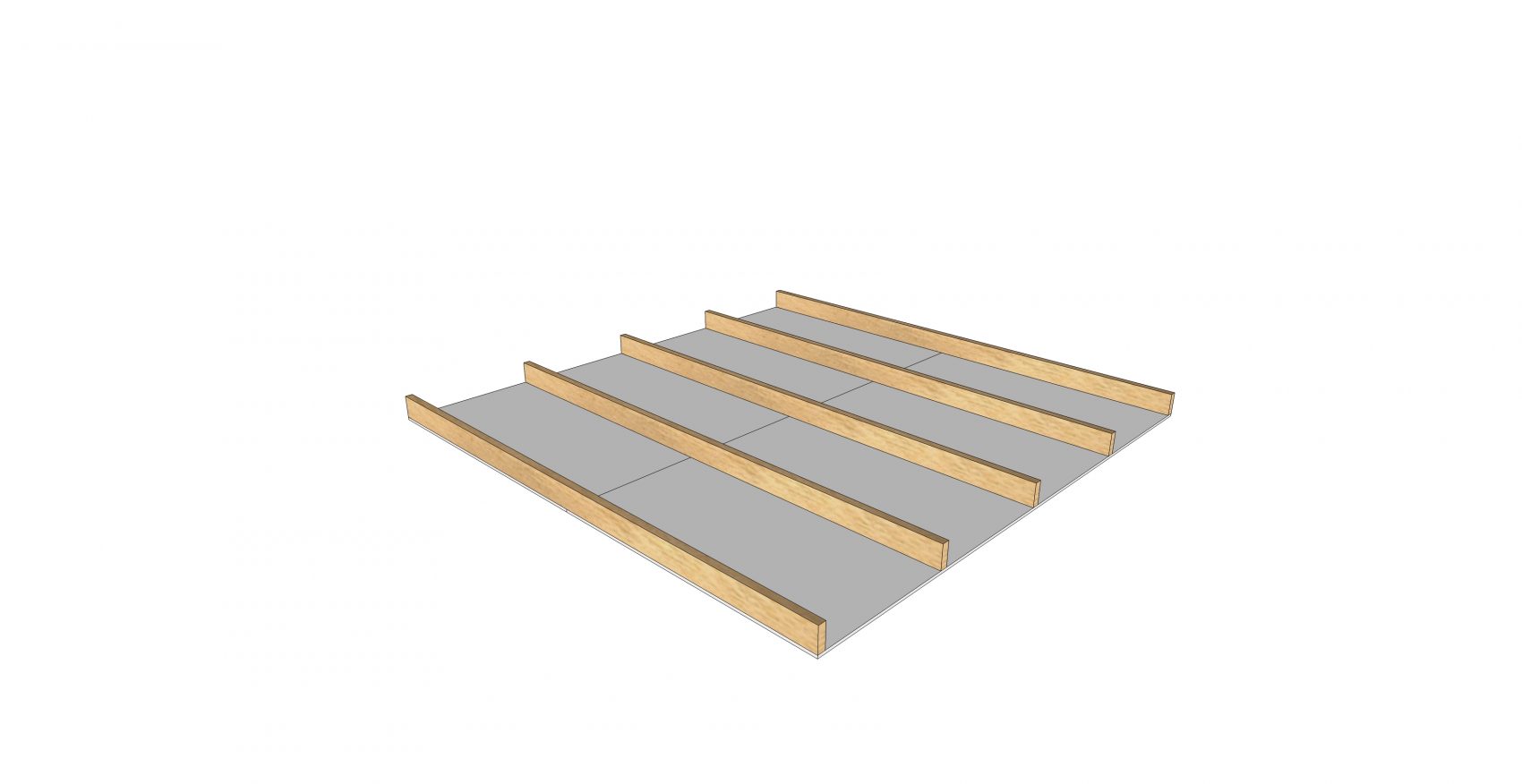

Top up insulation on top of and at right angles to ceiling joints and ceiling insulation

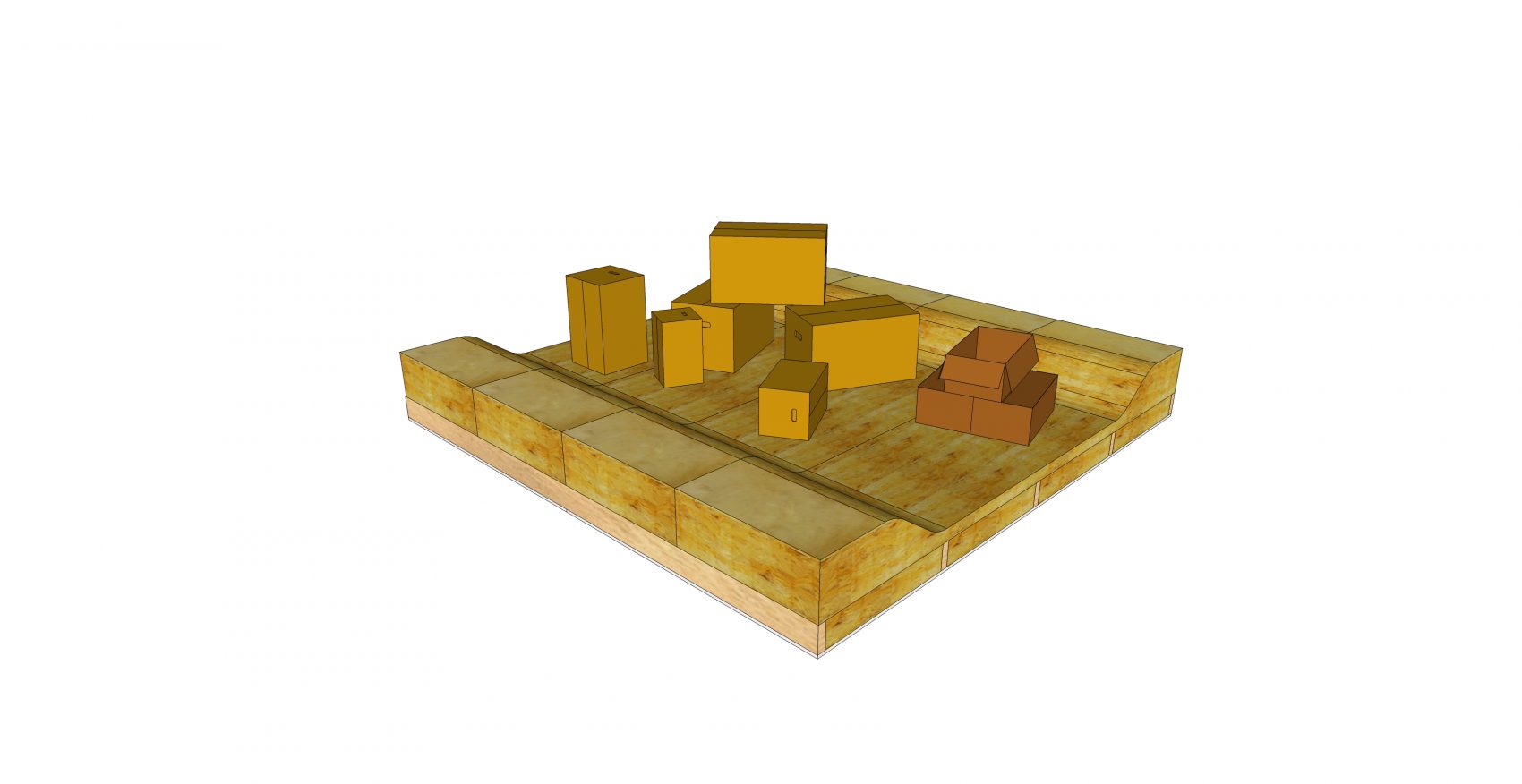

Squashed loft insulation with possessions stored on top of top-up insulation

Squashed loft insulation with possessions stored on loft deck boards on top of top-up insulation

If you remove the possessions from the loft deck boards, the boards continue to squash the loft top-up insulation

A step in the right direction:

- Deep loft joists on top of and at right angles to the ceiling joists; but they form a thermal bridge through the top up insulation

An improvement:

- Shallow loft deck joists in two layers, the first layer is at right angles to the ceiling joists and the second layer is at right angles to the first layer; top up insulation is laid between each layer of loft deck joists at right angles to the ceiling insulation layer below.

- Thermal bridging is reduced to the joist crossings rather than the whole length of the joist in the previous diagram.

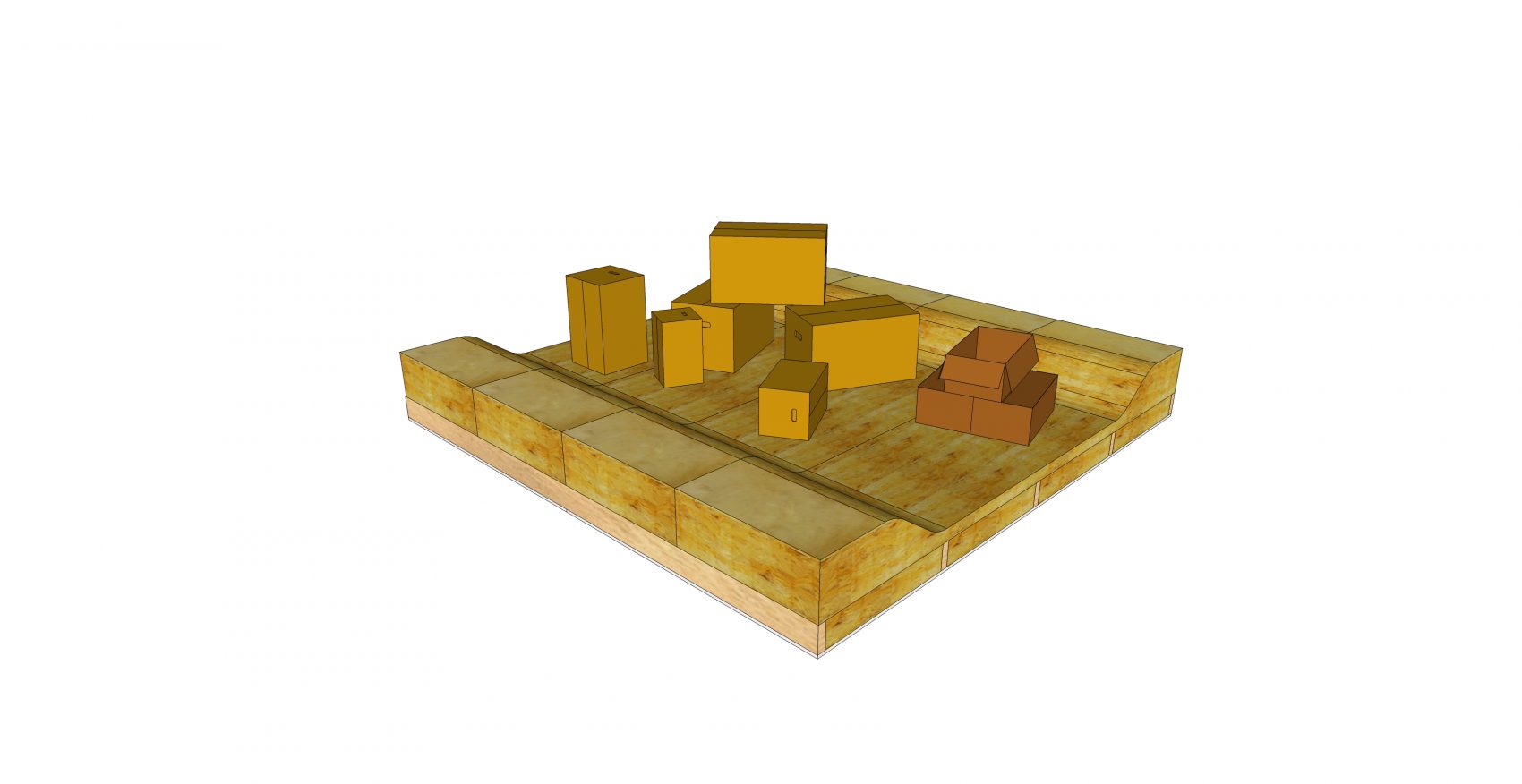

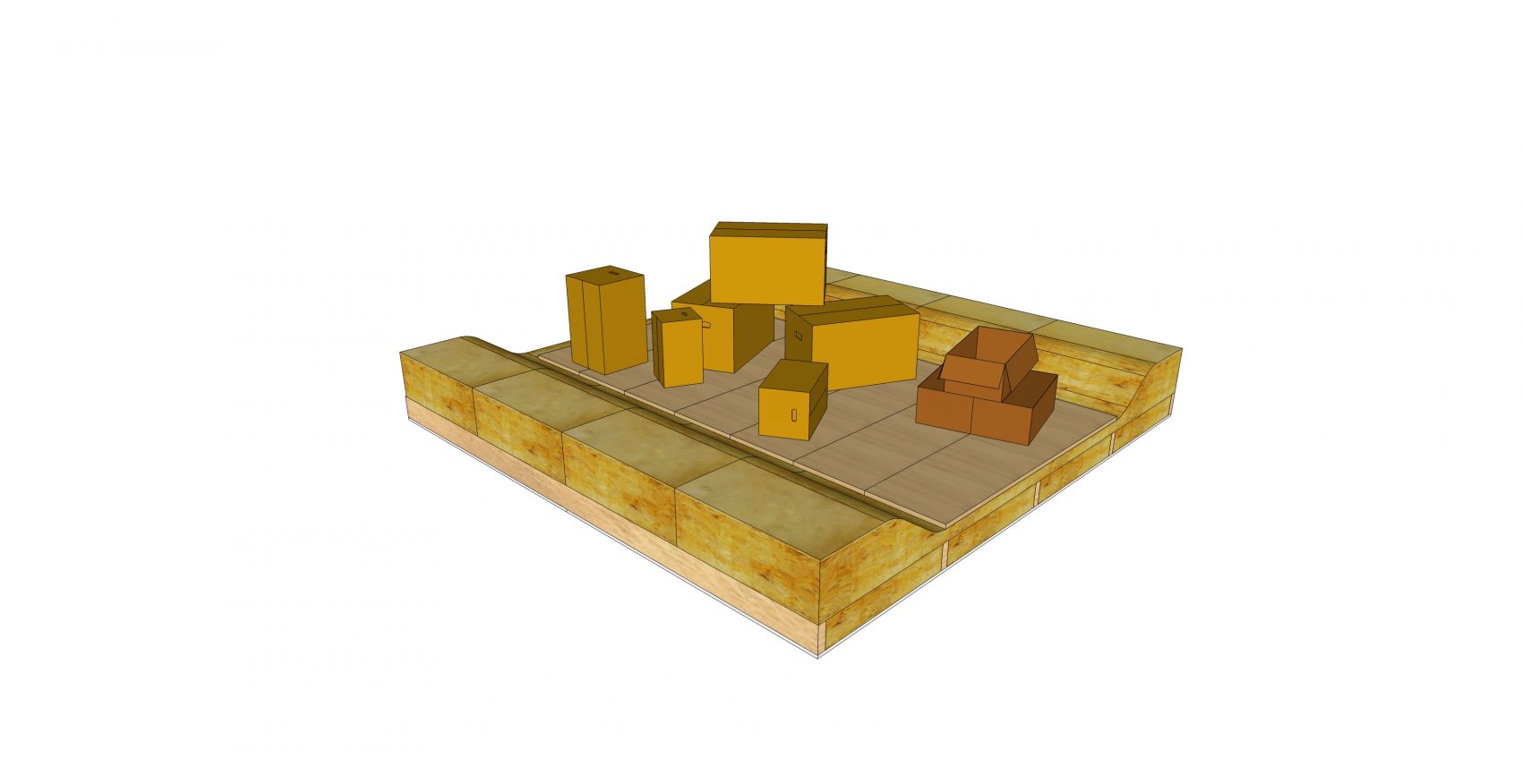

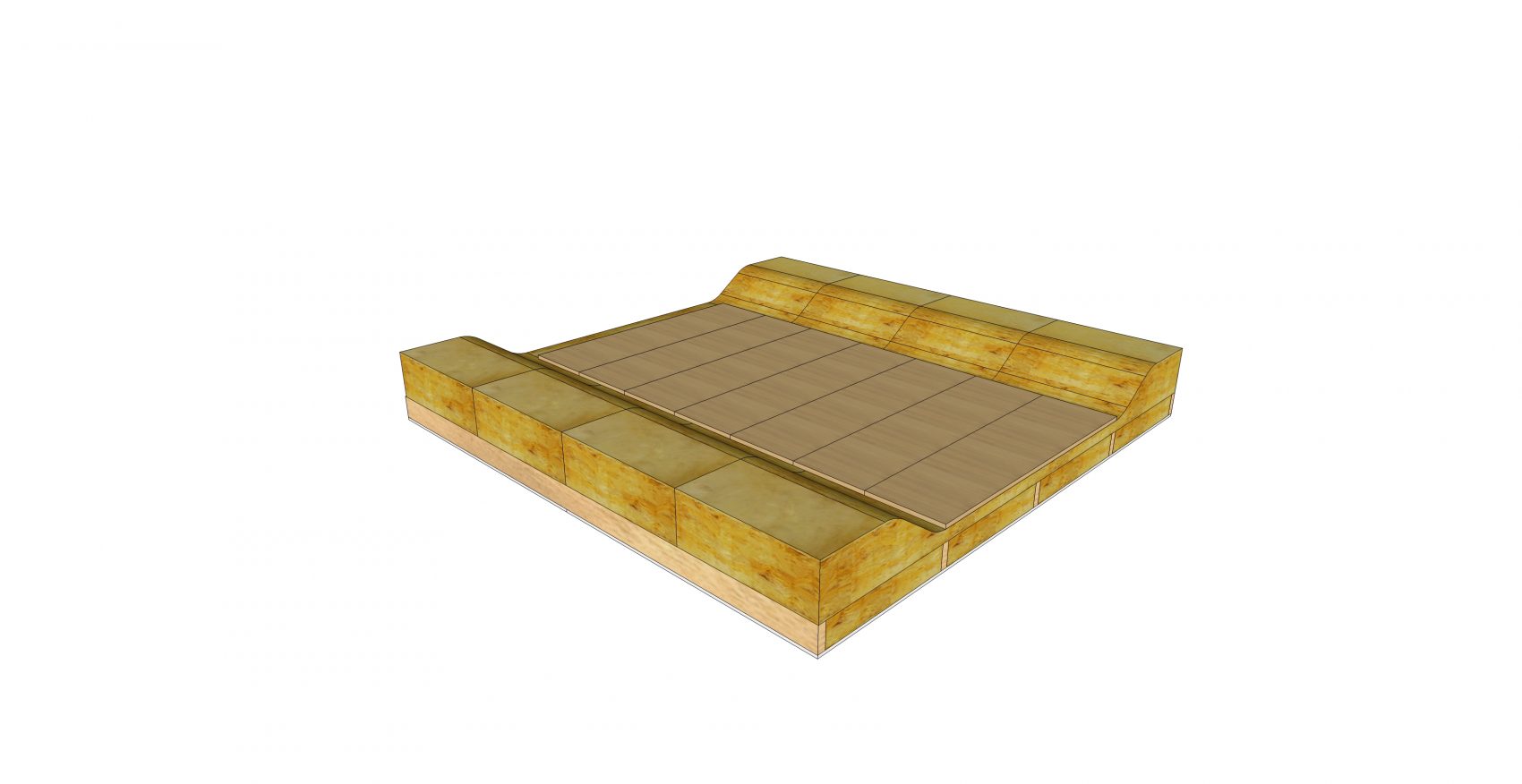

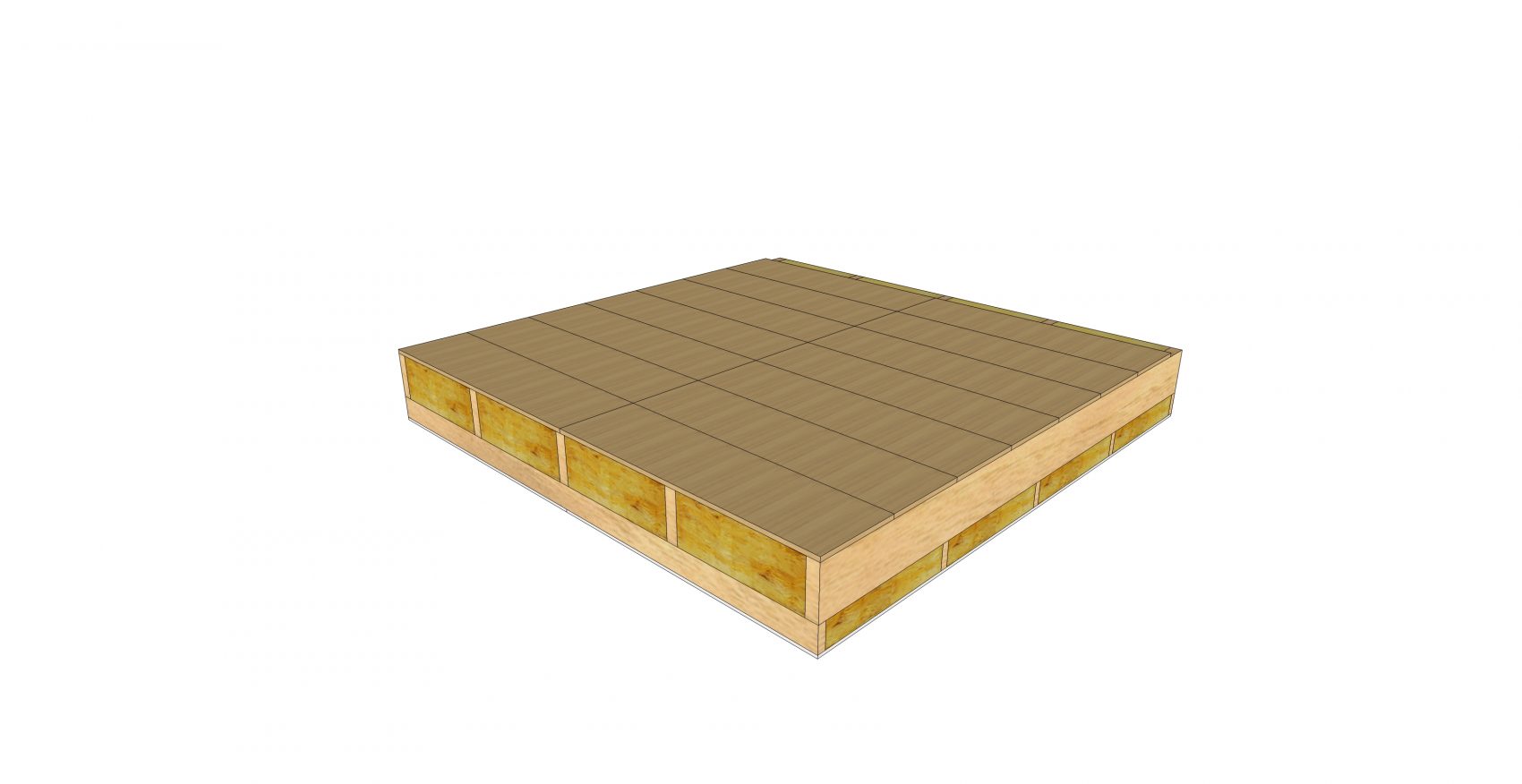

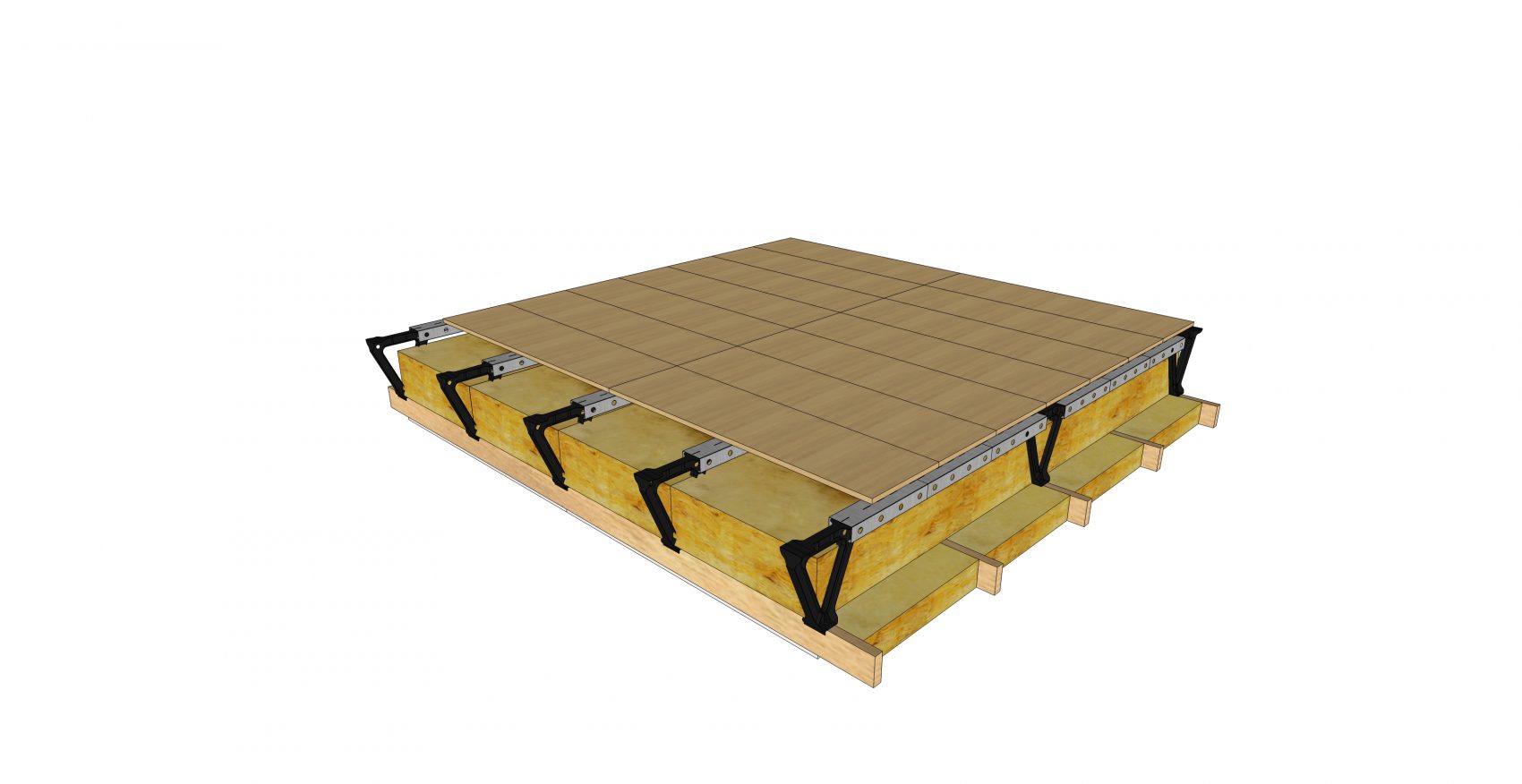

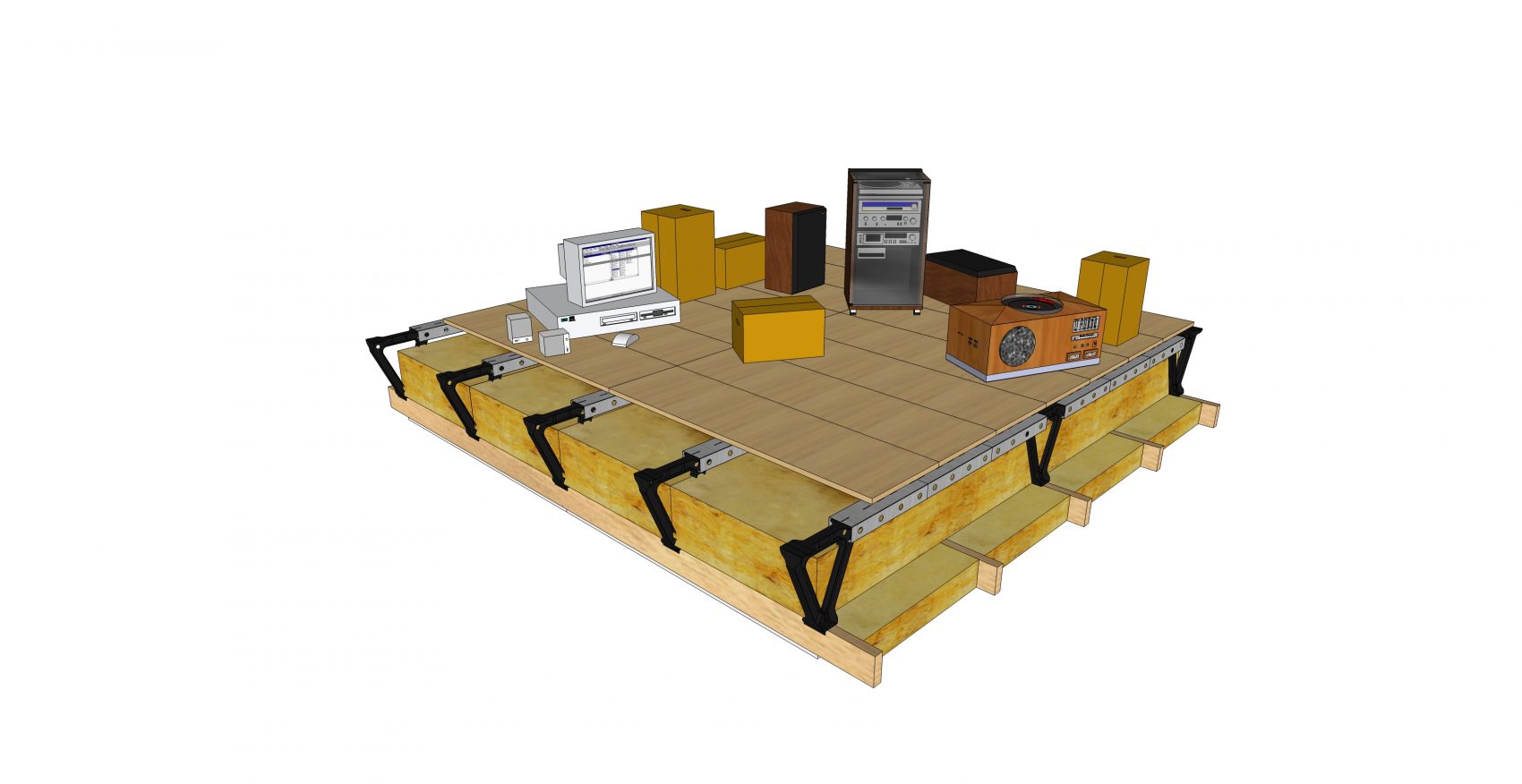

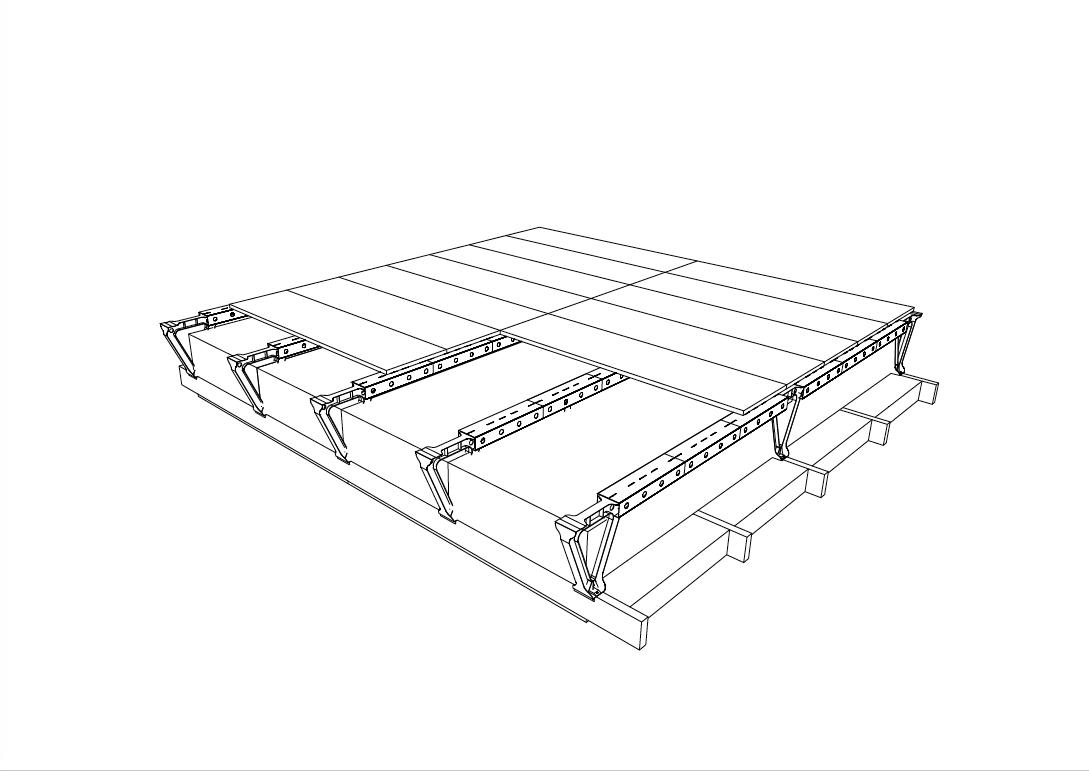

Sequential build up of LoftZone StoreFloor Loft Access/Storage Decking

Uninsulated Loft Ceiling

Inadequately insulated Loft Ceiling (Insulation is laid in depth of ceiling joists)

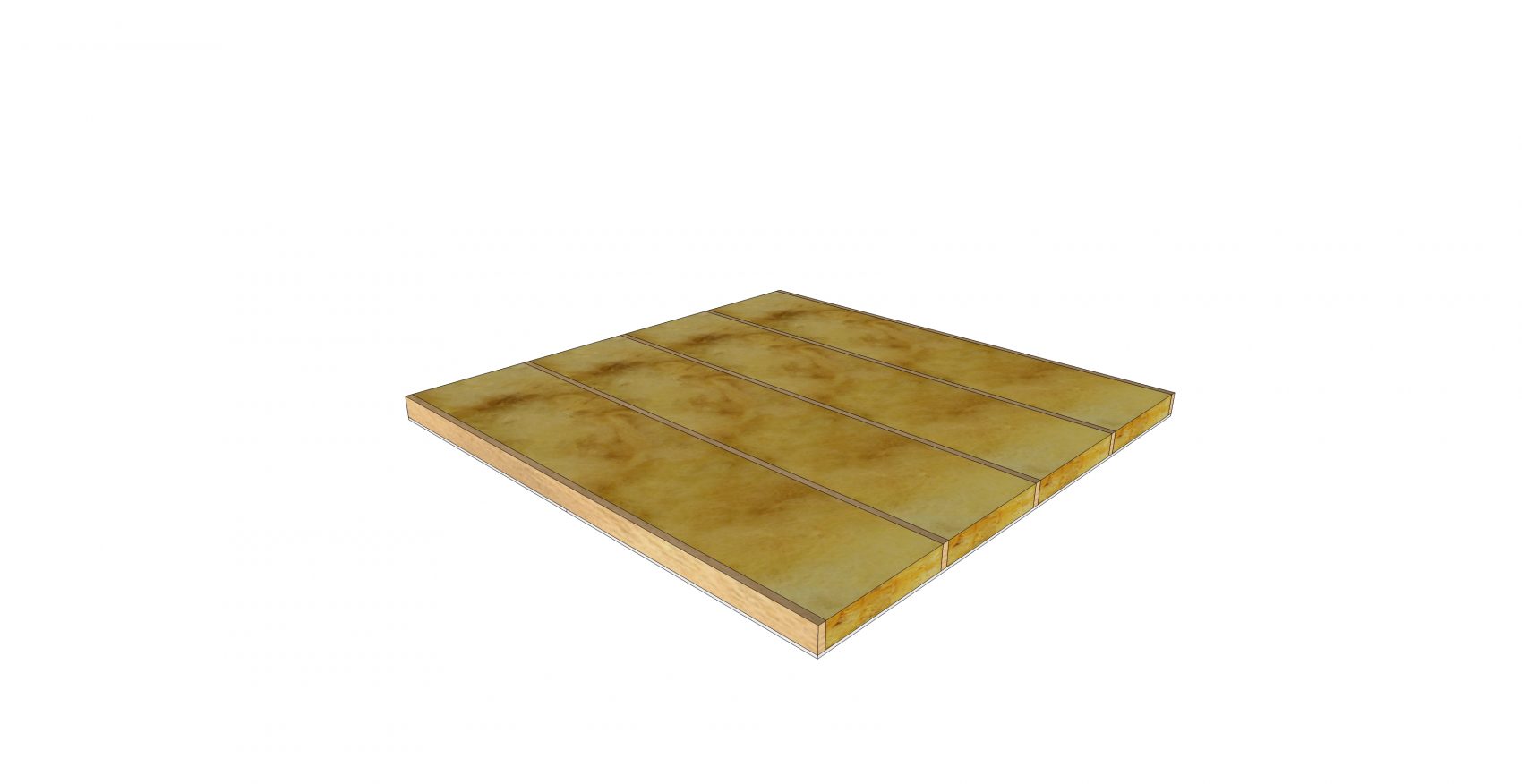

LoftZone StoreFloor supports and crossbeams bearing on ceiling joists

Loft Deck boards bearing on LoftZone StoreFloor Cross beams (partial installation)

Loft Deck boards bearing on LoftZone StoreFloor Cross beams (complete installation)

Possessions on the LoftZone StoreFloor deck and no squashed loft Insulation

3D CAD file available in SketchUp 3D and AutoCAD DWG formats

Line Drawing of 3D CAD file

Line Drawing of 3D CAD file

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

20th December 2016 – 16th May 2021