GBE H21 Timber Weatherboarding Outline

GBE > Encyclopaedia > Code > Outline > G#10281

About:

GBE H21 Timber Weatherboarding Outline

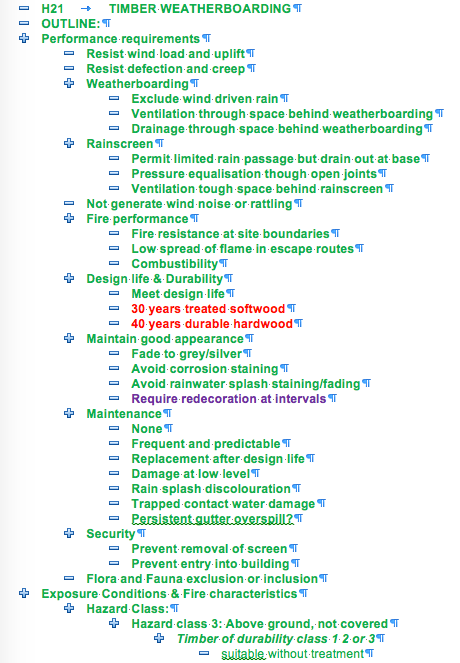

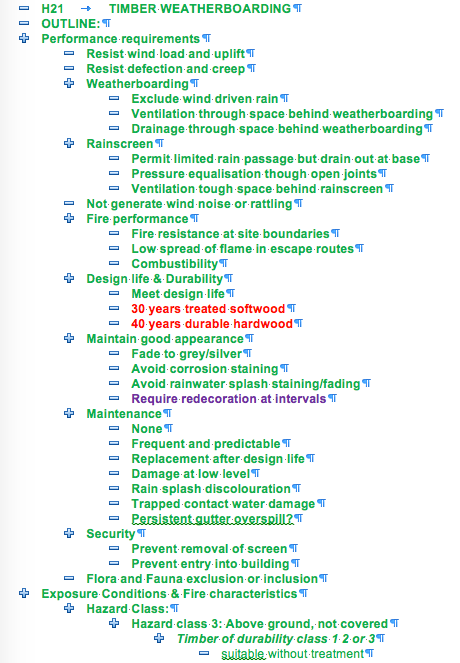

Outline:

- Outlines are the essence of the topic in a hierarchical order

- They could become the core of an Expert System or Design and Decision Tool

- The colour coding in the word file highlights:

- Green Environmental Options

- Violet Normal Practice

- Red Missing information

- (in the book it was extracted from)

GBE H21 Timber Weatherboarding Outline

NB: %%% Requires formatting (indenting)

Performance requirements

- Resist wind load and uplift

- Resist defection and creep

- Weatherboarding

- Exclude wind driven rain

- Ventilation through space behind weatherboarding

- Drainage through space behind weatherboarding

- Rainscreen

- Permit limited rain passage but drain out at base

- Pressure equalisation though open joints

- Ventilation tough space behind rainscreen

- Not generate wind noise or rattling

- Fire performance

- Fire resistance at site boundaries

- Low spread of flame in escape routes

- Combustibility

- Design life & Durability

- Meet design life

- 30 years treated softwood

- 40 years durable hardwood

- Maintain good appearance

- Fade to grey/silver

- Avoid corrosion staining

- Avoid rainwater splash staining/fading

- Require redecoration at intervals

- Maintenance

- None

- Frequent and predictable

- Replacement after design life

- Damage at low level

- Rain splash discolouration

- Trapped contact water damage

- Persistent gutter overspill?

- Security

- Prevent removal of screen

- Prevent entry into building

- Flora and Fauna exclusion or inclusion

- Exposure Conditions & Fire characteristics

- Hazard Class:

- Hazard class 3: Above ground, not covered

- Timber of durability class 1 2 or 3

- suitable without treatment

- sapwood removed

- Timber of durability class 4 & 5 not suitable

- Preservative treated timber including sapwood is suitable

- Heat treated timber suitable

- Internal

- Fire

- No requirements

- Escape route

- Surface spread of flame BS 476:Part 7: Class 1

- Building Regulations Approved Document B: Class 0

- Splinter free passage or touching

- Sawn, planed and arises removed

- Sawn, planed arises removed and sanded

- Sawn planed arises removed and sand blasted

- External

- Weather

- Undercover

- Not covered

- Sheltered

- Severe

- Wind driven rain index

- Humidity

- Precipitation

- Fire

- No requirement

- Boundary proximity condition (fire)

- Surface spread of flame BS 476:Part 7: Class 1

- Building Regulations Approved Document B: Class 0

- Shading (Differential fading)

- Avoid projecting eaves

- Shading to top of cladding and soffits below fascias

- Avoid projecting verges

- Shading to cladding and soffit below barge board

- Consider pre-fading boards

- Consider coloured decorative coating

- Long term maintenance

- Proximity to horizontal splash surface

- Contact (avoid always)

- Window sills

- Door thresholds

- Cladding sills/flashing/drips

- Handrails

- Copings

- Close (Avoid if possible)

- Cladding sills/flashing/drips

- Minimum 15 mm. gap and sloping down and out

- Clearance sufficient for ventilation of batten zone

- Insect mesh at base and top of batten zone

- 200 splash height

- Ground level

- Consider planting or gravel mulch to disturb splash

- Balconies

- Consider open grille decking against building

- Access walkways

- Consider open grille decking against building

- Flat roofs

- Consider loose gravel solar shading

- 200-250 mm. (avoid textured surfaces (sawn): risk of capillary attraction, provide drip profile)

- 450 mm. (suitable for most choices of surface finish)

- Framing:

- Generally

- Metal: Not in contact

- Timber:

- Not in contact

- Joinery framed (in contact)

- Mild steel frames

- Hot dip galvanized

- Sacrificial Zinc rich coating

- Stainless steel frames

- Grade: 316 Marine grade

- Timber

- Same species, treatments, Surface, Finish, MC,

- Different species, treatments, surface, finish, same MC

- Flashings:

- Material compatible with adjacent roofing/cladding

- Material compatible with acidic tannin

- Coated metal:

- Leave protective films in place

- (not exceeding manufacturer recommendation)

- Aluminium (high % recycled content)

- Polyester Powder coated

- Anodized

- PVF2 coated

- Steel

- Hot dip galvanized

- Hot dip galvanized and sacrificial zinc rich coating

- Hot dip galvanized and Polyester powder coating

- Hot dip galvanized and painted

- Alternative splash zone materials (recessed)

- Overhang cladding beyond wall

- Concrete plinth shown

- Concrete plinth/DPM/Protection

- Slates placed against plinth, dry joint, soil retained

- Paving slab turned up forming skirting, dry joint, soil retained

- Reconstructed stone plinth units, lime mortar

- Brick in lime mortar

- Plastics wood substitutes

- Durability

- Natural durability BS EN 350 Parts 1 & 2

- Class 1 Very Durable

- Remove sapwood

- European Oak (exceptional)

- Achievable using acetylation treatment

- Class 2 Durable

- Remove sapwood

- European Oak (normal)

- Class 3 Moderately Durable

- Remove sapwood

- Class 4 Slightly Durable

- Remove sapwood

- European Redwood (Pinus sylvestris)

- Scots Pine (Pinus sylvestris)

- Requires preservative in cladding applications

- Class 5 Not Durable

- Remove sapwood

- Requires preservative in cladding applications

- Life Expectancy

- Treated Softwood: 30 years

- Durable Hardwood: 40 years

- Maintenance Regimes (desired frequency and complexity)

- None

- No decoration, fade to silver (external exposed)

- Intensive

- Regular sanding/stripping and over coating

- Regular staining/oiling/waxing

- Guarantee Requirements

- Certification

- NHBC

- 10 years normally

- Zurich

- 15 years normally

- Other

- BLP

- Supplier/Installer back to back?

- Timber sourcing certification

- Treatment Certification

- Strength ad suitability certification

- PII covered engineer with reclaimed timber

- Moisture movement

- General:

- not all timbers fit these groups neatly

- frequent uptake and loss of moisture in unfinished wood can lead to surface checking (small cracks)

- Small movement timbers: 1% for 5% change in MC

- Medium movement timbers: 1% for 4% change in MC

- Home grown Oak

- Will develop small surface cracks but will not affect durability

- European Redwood (Pinus sylvesris)

- Heat or chemical treatment without preservatives

- Large movement timbers: 1% for 3% change in MC

- Avoid in cladding

- Sustainable Certification

- FSC

- FSC Certified

- FSC Chain of Custody

- FSC Project Chain of custody

- FSC Recycled content (applicable to panel products)

- FSC Reclaimed (not yet formally established)

- Non-FSC Local source, sustainable forestry

- PEFC

- PEFC Certified

- PEFC Chain of Custody

- PEFC Project Chain of custody

- PEFC Recycled content (applicable to panel products)

- Non-PEFC Local source

- Timber Quality

- Sapwood General

- Treated sapwood is acceptable

- Exclude sapwood if untreated

- Durable hardwoods

- Knots BS 1186 Part 3

- Classes dictate size and frequency of knots

- Class CSH

- maximum 6 mm. diameter knots

- Intended for small sections

- Not appropriate for cladding

- Class 1

- For planed and unfinished boards

- For prestigious buildings

- Easily available

- Douglas Fir

- Western Red Cedar

- Tropical hardwoods

- More difficult to obtain

- May prove expensive in otherwise low cost species

- European redwood

- European whitewood

- European Larch

- European Oak

- Class 2

- Increasingly accepted for cladding

- Unfinished and transparent finishes

- Temperate hardwoods

- European oak

- Class 3

- Traditionally acceptable for cladding

- BS EN 15146

- Addresses knots

- Also addresses:

- Acceptability of end splits

- Shakes and checks

- Presence of resin pockets

- Relates to each species and defines two grade

- Grade A

- Grade B

- Profiles: Take care:

- many profiles not commercially available

- not necessarily represent good practice in design or purpose made profiles

- BS EN 14915

- Characteristics, evaluation of conformity and marking

- Reaction to fire

- Formaldehyde content

- Pentachlorophenol content

- Water permeability

- Largely irrelevant to claddings with ventilated cavity

- Thermal conductivity

- Largely irrelevant to claddings with ventilated cavity

- Preservative treatment

- Manufacturing controls

- Good practice in construction

- Species

- Species Applicable

- Softwood

- Local

- Native

- European Larch (Larix deciduas)

- care with Sustainable Certification

- Class 3 moderately durable

- Small movement

- Less dense, strong and knot-free

- Also suitable for shingles and shakes

- Spruce (European whitewood) (Picea abies)

- Class _ durability

- ____ movement

- Scots Pine (European redwood) (Pinus sylvestris)

- Class 4 Slightly durable

- Heat or chemical treatment not preservative

- Medium movement

- Non-native

- Western Red Cedar (Thuja plicata)

- (UK grown less durable than North American class 2) (Remove sapwood)

- Small knots common in UK grown

- Small movement

- BS 8417: 60 year service life

- Resistant to preservative treatment

- High tannin content corrosive: protect porous and steel or iron materials below

- Soft and brittle: Avoid applications prone to mechanical damage: low level

- Avoid unfinished where high levels of pollution present (traffic and industrial processes)

- Also suitable for shingles and shakes

- Douglas Fir (Pseudotsuga menziesii)

- (UK grown less durable Class 3-4 moderately to slightly durable than North American Class 3)

- Moisture movement: _

- Resistant to treatment

- Can be left unfinished to fade

- Requires preservative treatment

- European Larch (Larix deciduas)

- care with Sustainable Certification

- Class 3 moderately durable

- Small movement

- Also suitable for shingles and shakes

- Scandinavia,

- Native

- European redwood (Pinus sylvestrius)

- Class 4 Slightly durable

- Heat or chemical treatment not preservative

- Medium movement

- European whitewood (Pinus abies)

- Class 4 Slightly durable

- Heat or chemical treatment not preservative

- Medium movement

- European Larch (Larix deciduas)

- care with Sustainable Certification

- Class 3 moderately durable

- Small movement

- Also suitable for shingles and shakes

- Russia, Latvia

- Native

- European redwood (Pinus sylvestrius)

- Class 4 Slightly durable

- Heat or chemical treatment not preservative

- Medium movement

- European whitewood (Pinus abies)

- Class 4 Slightly durable

- Heat or chemical treatment not preservative

- Medium movement

- Siberia

- Native

- European Larch (Larix deciduas)

- care with Sustainable Certification

- Class 3 moderately durable

- Small movement

- Very slow grown

- Dense, straight grained and less knotty

- Also suitable for shingles and shakes

- Alpine

- Native

- European Larch (Larix deciduas)

- care with Sustainable Certification

- Class 3 moderately durable

- Small movement

- Very slow grown

- Dense, straight grained and less knotty

- Also suitable for shingles and shakes

- North American

- Native

- Californian Redwood

- Class 2 durable

- infrequent use in UK

- Also suitable for shingles and shakes

- Douglas Fir (Pseudotsuga menziesii)

- Aka Oregon Pine, British Columbian Pine

- Acidic with high tannin content

- Small movement

- Class 3 Moderately durable

- Straight grained, robust wood

- Can be untreated and unfinished

- Western Red Cedar (Thuja plicata)

- Durability Class 2) (Remove sapwood)

- Straight grained, largely free of knots

- Small movement

- BS 8417: 60 year service life

- Resistant to preservative treatment

- High tannin content corrosive: protect porous and steel or iron materials below

- Soft and brittle: Avoid applications prone to mechanical damage: low level

- Avoid unfinished where high levels of pollution present (traffic and industrial processes)

- Expensive

- Also suitable for shingles and shakes

- Asia/Pacific

- Native

- Radiata Pine

- Class 4 slightly durable

- requires treatment

- Don’t know

- Western Hemlock

- Class 4 slightly durable,

- requires treatment

- Temperate

- Southern Yellow Pine

- Class 4 slightly durable,

- requires treatment

- Temperate Hardwood

- Local

- Native

- English Oak (Quercus robur)

- Shorter lengths than European

- 2.4 m long normally

- 150 mm. maximum width

- Durability Class 1 Very Durable (Remove sapwood)

- Medium movement

- Can be used green (un-dried)

- Soft and workable whilst green

- Once dry becomes extremely hard and resistant to mechanical damage

- High tannin content corrosive: protect porous and steel or iron materials below

- Resistant to coatings

- Can be left unfinished to fade to grey

- FSC and PEFC

- Also suitable for shingles and shakes

- Welsh Oak (Quercus robur)

- Source: Coed Cwmry, Small section?

- As English Oak

- Sweet Chestnut (Castanea sativa)

- 2.4 m long normally

- 150 mm. maximum width

- Durability Class 1 Very Durable (Remove sapwood)

- Small movement

- Can be used green (un-dried)

- Soft and workable whilst green

- Once dry becomes extremely hard and resistant to mechanical damage

- High tannin content corrosive: protect porous and steel or iron materials below

- Resistant to coatings

- Can be left unfinished to fade to grey

- FSC by the forestry commission

- Available in relatively small quantities

- Also suitable for

- shingles and shakes,

- post and beam construction

- Elm

- In short supply

- classed as 5 non durable

- but performs better than that

- Used in waney edge boarding

- European

- Oak (Quercus robur)

- France, Germany, Eastern European

- Longer lengths than UK Home grown

- ___ m long normally

- 150 mm. maximum width

- Durability Class 1 Very Durable (Remove sapwood)

- Medium movement

- Can be used green (un-dried)

- Soft and workable whilst green

- Once dry becomes extremely hard and resistant to mechanical damage

- High tannin content corrosive: protect porous and steel or iron materials below

- Resistant to coatings

- Can be left unfinished to fade to grey

- FSC and PEFC

- Also suitable for shingles and shakes

- North American

- Native

- American White Oak (Quercus Alba)

- Kiln dried suitable for internal use

- Can lead to problems if used externally

- Can lead to extensive shakes

- PEFC

- Tropical Hardwood

- General Issues

- Take particular care with Certification

- Durability Class 1 Very durable or 2 durable

- Dense or very dense

- Small or medium movement

- Some will darken upon exposure initially

- avoid treatment: probably unnecessary

- Suitable for use undecorated

- Will bleach to grey after exposure for long period

- African

- Small amounts of certified wood

- Far East

- Illegal Logging rife

- Primary species

- Iroko

- Endangered species

- Plantation grown with certification available

- Teak

- take care with sourcing and certification

- Central & Southern America

- FSC Certified available

- Seek detailed performance characteristics of subspecies

- Seek availability information

- Seek length and sizes information

- Secondary species (less well known)

- Angelim

- Cumaru

- Louro

- Itauba

- Jatoba

- Kauri

- Massaranduba

- Purpleheart

- Tatajuba

- Options and Alternatives

- Designer Preference

- Species to avoid

- Alternatives

- Greenpeace and FoE have lists

- Performance Specification of timber (avoiding species specification)

- Treatment

- General issues

- Service life BS 8417

- Durable species or treatment

- Up to 60 years (normal building design life)

- Untreated

- Durability to match or exceed exposure class

- Preservative pre-treated (BS 8417)

- Chemical

- CCA (Copper Chrome Arsenic)

- no longer permitted

- (in domestic applications)

- Where children present

- Where food growing may occur

- No longer made?

- Water-borne Copper-Organic

- Up to 60 years

- Organic-Solvent

- Up to 60 years

- Water-borne micro emulsions

- Up to 60 years

- Mineral

- Boron Salts

- Up to 30 year life

- WPA Manual

- Methods:

- Immersion in liquid

- Pressure and vacuum in liquid in vessel

- Pressure and double vacuum in liquid in vessel

- Low pressure spraying

- Unacceptable except:

- Local application to previously treated timber

- after cutting planning and drilling

- end grain sealer

- Applicability:

- If timber to be left unfinished:

- Water-borne copper-organic

- Affect moisture content of the wood

- Greenish tinge to wood

- Will fade over time

- Must be fully dried before handled or used

- If the timber to be coated or stained

- Light organic solvent

- Do not increase moisture content of the wood

- Less risk of distortion of profile

- Must be fully dried before handled or used

- Water-borne micro-emulsions

- Do not increase moisture content of the wood

- Less risk of distortion of profile

- Must be fully dried before handled or used

- Boron salts

- 30 year life

- Water soluble and susceptible to leaching

- Fire Treatment

- Modified timber

- Generally:

- Allows cheaper and readily available timber of lesser durability to be used without preservatives

- Modification is throughout the section

- Reduces moisture absorption and moisture movement

- Process tends to darken the wood

- Preservative treatment only penetrates to a limited depth

- Chemically Modified timber

- Process

- Impregnate wood

- Chemical reaction with wood

- Effect

- Render the wood more durable

- Improves moisture resistance

- Improves dimensional stability

- Improves coating performance

- Extends coating maintenance frequency

- Raises timber durability

- European redwood

- European whitewood

- Acetylation

- Pressure impregnate wood with acetic anhydride

- derivative of acetic acid (Vinegar)

- Raises pine to Durability Class 1

- Proprietary

- Product Reference: Accoya

- Manufacturer: BSW timber

- Heat treated timber

- Process:

- Dries the wood

- Heats the wood

- Reduces the natural nutritional content of wood

- Discourages fungi and insects

- Effect

- Timbers suitable for hazard category 3

- (above ground, not covered)

- Suitable for cladding

- 30 year life

- Advantages

- Throughout whole section

- Halves the moisture movement of timber

- Disadvantages

- Darkens appearance

- This should fade due to sun bleaching if unfinished

- Makes the timber softer and more brittle

- Similar to Western Red Cedar

- Use adequate number of fixings

- Loss of fastener pull out strength

- Proprietary

- Finland

- Product Reference: Thermowood

- Manufacturer: Finnforest UK Ltd.

- Holland

- Product Reference: ___

- Manufacturer: ____

- Additional opportunities

- Similarly modified softwood battens are available

- But they are softer and more brittle than unmodified

- Consider unmodified softwood

- Fire Protection

- Fire treatment

- Requirements

- Limit “Unprotected cladding”

- Within 1 m from site boundary:

- Of greater height than __ m.

- Building Regulations Approved Document B Class 0

- European Class B

- Or better

- Applications

- Vacuum/Pressure treatment

- Type:

- External exposure

- Leach resistant

- Humidity resistant and maintained protective coating

- Internal exposure

- Effectiveness

- Natural permeability of wood

- Sapwood easily treated

- Heartwood can be resistant to treatment

- Softwoods

- European Larch quite resistant

- Hardwoods mostly resistant to treatment

- Manufacturers know the species and thicknesses that can be treated to Class 0/Class B

- WPA Manual: Industrial Flame retardant for solid timber and panel products

- Treated

- Treated and kiln dried

- Cavity barriers

- Requirements

- Building Regulations Approved Document B

- Different in each country?

- Smoke and flame

- Counterproductive for ventilation and drainage cavities

- Stop and start the cavity above and below

- Provide drips etc. at each floor

- Locations

- Party walls

- Solid 50 x 50 mm. batten can be used at party walls

- Party floors

- Intumescent honeycomb

- Intumescent strip or tape

- Intumescent paint

- Around window openings

- Boundaries

- Edges at change of materials

- Breather membranes

- At re-entrant

- In line

- No need for vertical DPC

- Turn breather membrane to close wall

- Hold in place with batten

- Damp proof course from cavity wall closing

- In-line or behind a vertical DPC

- Extend the DPC to cover joint between any framing or sheathing of the wall

- Pre-compressed foam sealing strip

- Instead of gunned sealant or mastic

- Maintain good contact over uneven surfaces

- Will continue to expand to fill any gaps

- Even if there is shrinkage or movement at interface of wall and timber

- Metal flashings

- Malleable metal flashings

- Lead

- Avoid below Acidic timber

- Avoid below WRC

- Avoid below mosses and algea

- Dressed over solid base

- Below windows

- Dressed back behind base of timber boarding

- Capping

- Not suitable as a capping or it will block ventilation of cavity

- May be used with open joint boarding

- Finishes

- Patination oil on face

- Bitumen coating on rear face against alkali materials

- Pressed metal

- General

- Profiled to self support and span

- Project from base and background

- Materials and finishes

- Aluminium

- Powder coated

- Anodized

- Copper

- Unfinished

- Pre-patinated

- Avoid below acidic timber

- Avoid below WRC

- Zinc

- Unfinished

- Recycled aluminium

- Powder coated

- Protective temporary peel off strip

- Anodized

- Protective temporary peel off strip

- Mild steel

- Unfinished not suitable below acidic species

- Galvanized

- Galvanized and powder coated

- Pre-drill before protection

- Protective temporary peel off strip

- Bitumen coating

- Bimetallic and electrolytic corrosion

- Avoid

- Copper below green acidic timber

- Lead below green acidic timber WRC & Oak

- Zinc below western red cedar (acidic)

- Zinc below green oak (tannin)

- Unprotected mild steel below green acidic timber

- mixing metals on one building

- different metals in contact

- Consider

- Temporary protection during tannin release

- More base metals towards the top

- More nobel metals towards bottom

- Copings

- Project over top edge of boarding

- Particularly exposed ends of vertical boarding

- Drip profile downstand

- 10 mm. clearance minimum

- Any further will not ensure clearance of the cladding below

- Shed water away from top edge

- Overshadowing will prevent the boarding below bleaching (if desired)

- Window opening top flashing

- Requires careful detailing

- Vertical boarding

- Flashing to extend into adjoining boards

- Boarding to be cut back to accommodate

- Flush boarding difficult

- Board on board okay

- Base of claddings

- Sloping top surface to drain out and down

- Projection beyond wall below

- Steep enough that any rain splash misses bottom of boarding

- Maintain 15 mm. gap

- Between bottom of board and top of flashing

- For drainage and ventilation

- Important with vertical boarding end grain absorption

- Prevent excessive wetting and discolouration

- Flashing to extend back full depth of cavity

- Dressed or pressed up, drilled and screwed to backing wall

- Breather membrane to overlap upstand onto flashing

- Gap between ends of boarding and other material

- 8-10 mm. gap for ventilation

- End grain of horizontal boarding

- Do not fill with any sealant

- Changes of direction, plain or angle

- external corners

- Strong visual impact

- Consider detailing at openings when detailing corners

- Horizontal boarding

- Solid timber set flush

- Create re-entrant corner with vertical battens

- Stop boards 8-10 mm. short of batten face

- Requires high quality workmanship

- Fix solid timber to battens

- 8-10 mm. shadow gap between boards and solid timber

- No sealant

- Covered corner

- Create corner with vertical batten

- Stop boards 8-10 mm. short of batten corner

- Cover ends of boards with corner piece

- Form L shaped corner piece

- tongued and grooved together

- 8-10 mm. anti capillary groove on two hidden faces

- No sealant

- Solid capped set flush

- Create re-entrant corner with vertical battens

- Fix solid timber corner batten to vertical battens

- Stop boards 8-10 mm. short of vertical batten face

- Requires high quality workmanship

- Form L shaped corner piece

- tongued and grooved together

- 8-10 mm. anti capillary groove on two hidden faces

- Cover corner batten with corner piece

- 8-10 mm. shadow gap between boards and corner piece

- No sealant

- Re-entrant corner

- Create re-entrant corner with vertical battens

- Stop boards 8-10 mm. short of vertical batten face

- Requires high quality workmanship

- Cover re-entrant corner battens with two boards of different dimension,

- First board widest

- Second board narrower by first board width

- one to each face

- 8-10 mm. shadow gap between corner boards and horizontal boarding

- No sealant

- Mitred corners

- Mitreing is not recommended

- Shrinkage will leave gap for moisture retention

- Moisture will lead to selling and moving apart

- Open joint Rainscreen horizontal boarding

- Mitred open joint corner

- Maintain normal vertical joint width at corner

- Accommodate tolerance and any variation

- Visible fasteners will be set back from corner

- Diagonal boarding

- Treat similarly to horizontal boards

- Exposing ends of boards needs accurate cutting

- High water run off

- 12 mm. gaps recommended

- Seal space behind vertical gap to prevent water entry

- Vertical boarding

- Board on board

- Cladding to corner

- Outer board at corner of one elevation

- Inner board (cut) at end of one elevation

- internal corners

- At openings

- Dimensional coordination is essential for appearance sake

- Work with board/lap/joint width

- Position openings to coordinate with boarding

- Avoid notches and split boards (poor appearance)

- Consistency is important

- Varying board widths or laps can solve dimensions but appearance may suffer

- Ribbon windows may simplify detailing

- Minimise cutting to minimise labour intensity (costly)

- Minimise cutting to minimise waste (costly)

- 3D consideration of flashings, DPC and sills essential

- Maintain integrity of defence against water entry

- Maintain pattern of visible fasteners around openings

- Eaves

- General

- The greater the overhang the more pronounced the shading and likelihood of differential bleaching of unfinished surfaces

- Projecting eaves

- Horizontal soffit

- Sloping soffit

- Fascia

- Verges

- Bargeboards

- Fascia

- Soffit

- Parapet

- General

- No overhang avoids shading and ensures consistent weathering

- Capping with lead will seal ventilation zone

- Capping with self supporting metal maintains ventilation

- See

- Moisture Content

- Green

- Seasoned

- Kiln dried

- Surface Texture

- Sawn

- risks of splinters

- Capillary attraction of splash water up surface

- More surface coating required for coverage

- Better protection with more coating

- Fine sawn

- Suitable for stains

- Sawn Planed

- Sawn Planed Arises eased

- Removes risk of splinters during handling

- Sawn Planed Sanded

- Sawn Planed Sand blasted

- Decoration

- Types

- General

- No decoration will lead to:

- timbers bleaching to grey/silver

- some friability of the surface

- particularly with softwood

- Decoration should be applied as early as possible

- Maximise the performance of the coating

- Uncoloured decoration is poor UV protection

- generally not suitable externally

- pigments are necessary

- Opaque coatings

- Offer best protection

- Translucency

- Can permit the figure, texture, grain and colour show through

- Colours:

- Can simulate natural colours

- Can contrast with manmade colours

- Dark colours offer greatest UV protection

- Dark colours raise the temperature

- Raised temperature will drive out moisture

- Drying timber may suffer cracking or checking

- Raised temperature can lead to resin exudation

- Permeability

- Can enhance the ability of the timber to dry out through stains and low build finishes

- Can protect from moisture uptake

- Film forming coatings

- Paints and varnishes

- Can resist moisture uptake

- Are too brittle upon aging

- Will crack as moisture movement occurs

- Lets moisture in

- Can trap moisture under surface in the wood

- Possible degradation of the wood

- Possible blistering, flaking and peeling of the finish

- Should ideally be extensible:

- To cope with moisture movement of timber

- Micro-porous coatings

- Are flexible enough to follow moisture movement

- Are permeable to permit loss of moisture from under the surface

- Apply to fine sawn surfaces for longer life than planed

- More coating needed for sawn surfaces

- Can help the wood retain its colour

- Application

- UK worst practice

- prime timber before building in

- Absorbent surface against permeable construction

- Scandinavian best practice

- full coating system on all faces

- Compromise

- Minimum one full topcoat on all faces

- Consistent moisture uptake and loss possible

- Shrinkage will not reveal uncoated surfaces

- Location

- Factory

- Controlled moisture content (if timber)

- Controlled humidity (in factory)

- No Precipitation

- Controlled wind movement

- Controlled sun (exposure of wood)

- Machine applied

- Controlled application rates

- Controlled drying

- On-site

- Uncontrolled moisture, humidity, wind, sun exposure, precipitation,

- Unpredictable on site labour skills

- Timber exposed to ultra violet light degraded

- Risk of inconsistent factory undercoat and site top coats

- Diminished life expectancy

- On-site maintenance

- Do not let bare timber to be exposed before maintenance

- Poor UV affected surface will lead to poor adhesion

- Hardwoods more difficult to gain penetration or adhesion

- Sand down or strip all film forming coatings

- Unfinished

- Weather and bleach naturally in UV sunlight

- General

- No further maintenance

- Long life possible

- Sun (UV light) bleaching to grey or silver colour

- Some will go to brown

- Bleaching will not affect the durability of the timber

- High levels of UV light do not reduce life expectancy

- More movement in the surface

- due to fluctuating moisture content

- Some surface checking (small cracks) may occur which will open and close

- Pollution and dirt accumulations higher on un-finished

- Can lead to blackening of the surface

- Low moisture movement species best

- Partial bleaching

- Affected by shading

- Eaves, verges, balconies, solar shading, rainwater goods, lights, signs, sills and drips

- Can be high contrast, unexpected and unacceptable

- It is a design failure rather than a materials failure

- Consider pre-bleached timbers

- Consider different detail in sheltered no-bleach zone

- Orientation affects rate of bleaching

- Slow: north east, north, north west

- Fast: south east, south, south west

- Shading by other buildings can affect rate

- Brake dust containing metal dust can react with tannin resulting in iron staining

- Blackening

- A number of causes

- Cladding in the vicinity of trees or heavy vegetation or where there is unusually high run off of moisture

- Exhaust fume pollution

- Brake dust from cars and trains containing metals can react with tannin resulting in iron staining

- Cement dust from local construction work

- Mild steel fasteners in acidic timbers reaction blackens fastener and timber

- Avoid all such risks

- Cleaning fluids are available but remove the source of the problem first

- Moisture content affecting colour or appearance

- Shading can maintain moisture content higher that that warmed by the sun

- Contact surfaces at base of cladding and other penetrations

- Maintain timber in wet condition

- Splash zones can keep moisture content high

- Splash 200 mm. and capillary attraction up sawn surfaces a further 250 mm.

- Eaves abutment with gables, blocked gutter overflow zone

- Consider different fastening regime to permit easy replacement

- Tannin

- High tannin content acidic timbers

- Run-off during bleaching process

- Porous materials below cladding

- Stone, brick, concrete, precast stone, renders

- Staining potential

- Avoid by design or temporary protection

- Softwoods

- Western Red Cedar

- Douglas Fir

- Hardwoods

- European Oak

- Finished

- Vapour tight

- Lacquered

- Painted

- Micro porous vapour permeable

- Low build stain high solids

- high build stain

- Stained

- Stain and wax (dangerous on decking)

- Oiled

- Waxed (dangerous on decking)

- Limed (traditionally on oak)

- Health issues

- Plant based

- Plant based solvent

- Water based solvent

- Mineral based

- Synthetic

- High VOC

- Low VOC (more chemicals)

- Installation appearance

- Co-ordinated design

- Corners

- Changes of level

- Parapets

- Openings

- Soffits

- Junctions with other materials

- Board layout

- Orthogonal shapes

- Non-orthogonal shapes

- Curved on plan

- Lends itself to vertical boarding

- Board on board works well

- T&G difficult

- Tight radii

- Lends itself to narrow boards

- Battens

- Can be made up in thin layers capable of negotiating curve

- Successive layers can be fixed together

- Nails

- Screws

- Joints must not coincide

- Curved on section

- Lends itself to horizontal boarding

- Overlap and shiplap work well

- T&G difficult

- Shallow angles can permit capillary attraction leading to water entry

- Tight curves open up joints to water entry into joint

- Sustained moisture content will lead to failure

- Curved on elevation

- Angled facades

- May accept vertical horizontal or sloping boarding

- Shallow angled façade or gable

- Cut end of vertical boards

- Avoid tapering horizontal boards

- Horizontal boards

- Additional batten to support tapered ends of boards

- Use of diagonal boards can sometimes simplify junction

- Combinations of the above

- Geometry may dictate board layout

- Vertical horizontal or diagonal board layouts

- Combination of the above

- Surface coverage

- Random length and joint locations

- Controlled length and joint locations

- Random width(s) and joint spacing

- Controlled width(s) and joint spacing

- Framed panels

- Unframed panels

- Off-site panelised prefabrication

- Boarded

- Vertical

- Diagonal

- Horizontal

- Mixed

- Battened

- Louvres

- Solar shading

- Rainscreen

- Tiled

- Shingles

- Shakes

- Tiles (appear like ashlar stonework)

- Boundaries

- Profiles, overlapping, gaps, butting T&G or TG&V

- Profiles

- Spaced battens

- Weathered top edge

- Drip profile

- Rain-screen open joint profiled edge boards

- Anti-capillary profiles

- Joint layout

- Board length limitations

- Softwood

- Species

- European redwood

- European Whitewood

- European larch

- Douglas fir

- Lengths

- Up to 4.8 m.

- Temperate Hardwood

- Species

- Sweet chestnut

- 2.0 – 4.0 m.

- Maximum: 5.0 m.

- European Oak

- 2.4 m. generally

- 2.0 – 4.0 m.

- Maximum: 5.0 m.

- Tropical hardwoods

- Species

- Varies

- 2.1 – 4.2 m.

- Maximum: 4.8 m.

- Width limitations

- European Oak

- 150 mm.

- Spacing and size and patterns

- Surface profiles

- Joint patterns & batten spacing

- Random or standardised lengths

- Random colour mixing

- Fixing appearance and spacing

- Joints

- Horizontal boarding

- Vertical end-joints

- Coincident with battens

- Standard batten widths insufficient for end joints

- Insufficient width batten

- Insufficient edge distance on batten

- Insufficient end distance on board

- Consistent length boards and all occur on same batten

- Use two battens side by side

- Spaced to match joint between board ends

- Timber frame background

- Use wide batten fixed in centreline of stud

- Panelised boarding

- On structural grid lines

- Lends itself to prefabrication

- Requires coordination of openings

- Labour intensive

- Requires accuracy for good visual effect

- Invites rejection by designers

- Wasteful of timber cutting to length

- Invisible joints

- Random location

- Coincident with battens

- Length of batten nailed to side of main batten

- To support ends of two boards

- Length 3 x board width

- Butt joint positions randomly staggered

- 5 mm. gap for ventilation and drainage of end grain

- Vertical boarding

- Horizontal end-joints

- Increasingly visible over time

- Wetting and swelling of lower board end grain

- Run-off from upper board

- Chamfer ends of boards outwards

- Seal top of lower board

- Gap: 5 – 8 mm.

- Coincident with battens

- Standard batten widths insufficient for end joints

- Insufficient width batten

- Insufficient edge distance on batten

- Insufficient end distance on board

- Consistent length boards and all occur on same batten

- Use two battens side by side

- Spaced to match joint between board ends

- Panelised boarding

- Storey heights

- Most species can be accommodated

- Lends itself to prefabrication

- Floor level joints can accommodate shrinkage, deflection, creep and structural settlement

- May accommodate cavity barriers between floors

- Requires coordination of openings

- Offcuts can be used under window openings

- Labour intensive

- Requires accuracy for good visual effect

- Invites rejection by designers

- Wasteful of timber cutting to length

- Jointing

- Finger jointing and end dowelling

- Will become economic

- Will become more commonplace

- Longer lengths overcome need for butt joints

- Reduce off-cut waste

- Invisible joints

- Random location

- Coincident with battens

- Length of batten nailed to side of main batten

- To support ends of two boards

- Length 3 x board width

- Butt joint positions randomly staggered

- 5 – 8 mm. gap for ventilation and drainage of end grain

- Chamfered outward and downward

- It may be difficult to exclude all sapwood:

- Permissible relaxations:

- No sapwood should be visible in exposed board face

- No sapwood should be present in board edges, lapping or jointing profile

- No sapwood should be present in end grain

- Sapwood which occupies less than 5 mm. width of the hidden face may be of unlimited length

- Sapwood which occupies more than 5 mm. width of the hidden face should be less than 500 mm. long

- Check the class specification and modify if required

- may be difficult to identify sapwood

- Board Orientation & Profile

- Horizontal

- General issues

- Most common

- Profiles: simple overlap, feather or square, rebated feather, shiplap

- Square edge

- thickness: 16-19 mm.

- overlap 25 mm.

- Heart side outwards

- Feather edge

- thickness: minimum 8 mm. to 16-19 mm.

- overlap 25 mm.

- thin edge at top

- Heart side outwards

- Rebated feather edge

- Thickness: minimum 8 mm. to 19 mm. low edge: 10 mm.

- Overlap 15 mm.

- Gap: 2 mm.

- Heart side outwards

- Ship lap

- Thickness: minimum 16 – 19 mm.

- Overlap 15 mm.

- Gap: 2 mm.

- Heart side outwards

- Horizontal T&G Jointed

- tongue uppermost

- Heart side outwards

- Thickness: 19-22 mm.

- Recommended board face width: 100 mm.

- Maximum board face width: 125 mm.

- T&G overlap 10 mm.

- Gap: 2 mm.

- Not V joint (used internally or vertically)

- Better with a rebated profile

- Open joint

- 30 degree sloping top and bottom edges

- Heart side outwards

- Widening gap towards back is better

- gap 8-15 mm.

- thickness 16-19 mm.

- Insect mesh behind

- Suitable for green timber, shrinkage less obvious

- strong shadow line

- UV light penetration effect on breather membranes to be taken into account

- Reduced spacing battens to reduce shrinkage movement

- Butted boards

- risky for capillary attraction

- end grain water penetration

- Diagonal (take care with profiles)

- General issues

- Longer span between H or V battens

- Diagonal battens?

- Reduce V or H batten spacing

- Thicker board (How thick?)

- Avoid V pattern abutments

- Consider A pattern abutments

- Avoid simple overlapping boards

- Avoid open butt joints in lengths

- Avoid butt joints use longer boards

- Heart side outwards

- Ship lap

- Thickness: minimum 16 – 19 mm.

- Overlap 15 mm.

- Gap: 2 mm.

- Heart side outwards

- Diagonal T&G Jointed

- tongue uppermost

- Thickness: 19-22 mm.

- Recommended board face width: 100 mm.

- Maximum board face width: 125 mm.

- T&G overlap 10 mm.

- Gap: 2 mm.

- Not V jointed (used internally or vertically)

- Heart side outwards

- Overlapping

- Vertical

- General Issues

- Consider lengths available and horizontal joints

- Avoid top of board below joints absorbing water

- Consider stopping and starting at floor levels

- Consider fire barriers at floor levels

- Allow for creep, deflection and settlement of the structure

- Consider a weather drip between storeys or panels

- Consider prefabrication of panels

- Vertical T&G Jointed

- Recommended width: 100 mm.

- Maximum width: 125 mm.

- Thickness: 22 mm.

- Shrinkage risks disengagement of T&G

- T&G overlap 10 mm.

- Gap: 2 mm.

- Can use V jointed

- Alternative: Rebated overlapping

- Heart side outwards

- Rebated overlapping boards

- Maximum width: 150 x 19 mm.

- Heart side outwards

- Board on Board

- Minimum 20 mm. overlap

- With or without Capillary grooves near the outer edges of both board touching faces

- Suited to curvilinear plan walls

- Tolerant of dimensional variation

- Gap created provides ventilation and drainage

- Gap created avoids need for counter-battens

- Wide boards on wide board

- 150 and 150 x 16 mm.

- Wide boards on narrow board

- 100 on 75 x 16 mm.

- Narrow boards on wide board

- 75 on 100 x 16 mm.

- Variety of board widths permits surface modelling

- Outer board: Heart side outwards

- Inner board: Heart side inner

- Open joint board

- Widening gap towards back is better

- gap 8-15 mm.

- thickness 16-19 mm.

- Insect mesh behind

- Heart side outwards

- Suitable for green timber, shrinkage less obvious

- strong shadow line

- UV light penetration effect on breather membranes to be taken into account

- Use of breathing sheathing board appropriate

- Reduced spacing battens to reduce shrinkage movement

- Open joint battens

- Widening gap towards back is better

- gap 8-15 mm.

- Size: minimum ex 50 x 50 mm.

- Insect mesh behind

- Suitable for green timber, shrinkage less obvious

- strong shadow line

- UV light penetration effect on breather membranes to be taken into account

- Use of breathing sheathing board appropriate

- Reduced spacing battens to reduce shrinkage movement

- Sloping

- Board on Board

- Minimum 20 mm. overlap

- With capillary grooves near the outer edges of both board touching faces

- Wide boards on wide board

- 150 and 150 x 16 mm.

- Wide boards on narrow board

- 100 on 75 x 16 mm.

- Narrow boards on wide board

- 75 on 100 x 16 mm.

- Outer board: Heart side outwards

- Inner board: Heart side inner

- Reduced spacing battens to reduce shrinkage movement

- Reduced batten spacing or sloping battens

- Fixing & Fastenings

- Choices

- Hardwood

- Screws (normal practice)

- At or close to 16% MC

- Allow for seasonal variation in MC

- Oversize drill holes

- Small movement timbers: 2 mm.

- Medium movement species: 2 mm.

- Clearance around shank

- Use countersunk screws

- Use oversize screws with bigger heads

- Maximum 150 mm. board width

- Locate screws ¼ board width in from edges

- Green timber

- Allow for considerable initial shrinkage

- Oversize drill holes

- Green timber: 4 mm.

- Washer needed

- Slotted hole washers

- Not easy to obtain

- Require alignment to permit movement

- Require positioning to maximise possible movement

- Recessed holes in timber face

- Oversized to permit movement of washer over timber in recess

- screw heads for use with washer

- Round head or pan head

- Sheeting screws with built in washers

- Rear face fixing

- Hardwood open joint boards

- Panelise boards with battens

- Screws through clearance holes

- Front face fixing

- Hardwood boards

- Panelise boards with battens

- Screw through front face and pellet or plug holes

- To treated softwood battens (normal practice)

- To same hardwood battens

- Expressed

- Demountability

- Single lap with exposed Phillips head screw

- Square edge board, horizontal boarding

- Feather edge board, horizontal boarding

- Socket in timber oversized hole, washer and screw

- open joint boarding

- Flat head nails at surface

- board on board

- Hidden

- Limited demountability

- Hidden J profile stainless steel fixing clips

- Fixed to vertical batten

- Horizontal shiplap or Open joint boarding

- With added slot in underside

- J profile hooks into slot

- Screw top of boards to battens through shoulder

- Similar principle to T&G

- Can allow for considerable shrinkage in board width

- Easy to engage in Joint

- Less liable to damage tongue

- Board can be held and aligned with wide clip

- Requires careful design for each application

- Taking in to account:

- Species, shrinkage, thickness, other characteristics

- Softwood

- Nails (normal practice)

- To treated softwood battens (normal practice)

- Non-demountable

- Lost head nails

- Horizontal boarding

- Open joint

- Square edge

- Feather edge

- Rebated feather edge

- Shiplap

- T&G

- Diagonal

- Vertical

- Secret fix nails

- Not recommended in T&G Joint

- Risk of tongue splitting

- Recommended in rebated T&G Joint

- Nail through shoulder

- Metals

- Acidic species e.g. Oak, WRC, Sweet chestnut

- Austenitic stainless steel

- Marine Environment: (tidal estuary and sea) Grade 316

- Otherwise Grade 304

- Weathers down to matt grey

- (Quercus Fencing fastenings)

- Galvanized steel

- Prone to damage when driving

- Mild steel

- Will stain timber and fastener purple-black

- Stain not removable

- Non acidic species

- Avoid ferrous if uncoated softwood boarding

- Galvanized steel

- Prone to damage when driving

- Protect by coating timber

- (Quercus Fencing fastenings)

- Brass

- Un finished hardwood

- Austenitic stainless steel

- Marine Environment: (tidal estuary and sea) Grade 316

- Otherwise grade 304

- Weathers down to matt grey

- Clips or washers same metal and grade

- Coated hardwood

- Austenitic stainless steel

- Marine Environment: (tidal estuary and sea) Grade 316

- Otherwise Grade 304

- Weathers down to matt grey

- (Quercus Fencing fastenings)

- Galvanized steel

- Prone to damage when driving

- Fastener sizes: Dictated by board thickness

- Nails

- Nails normally driven just below the surface

- allow for timber shrinkage

- avoiding nail becoming proud of surface

- Nails 20 mm. from end of board

- Nails 15 mm. from edge of board

- Spacing: batten spacing dictates.

- Small head or siding nails can pull through soft WRC

- Larger heads recommended for WRC

- Standard round wire nails:

- 2.5 x thickness of board

- T&G: 19-22 mm. = 48-55 mm.

- Other: 16-19 mm. = 40-48 mm.

- Annular ring-shank nails

- Improved holding power

- 2 x thickness of board

- T&G: 19-22 mm. = 38-44 mm.

- Other: 16-19 mm. = 32-38 mm.

- Pneumatically driven nails

- D shaped heads may not be visually acceptable

- Virtually headless pins are not recommended

- Screws:

- 2 x thickness of board

- T&G: 19-22 mm. = 38-44 mm.

- Other: 16-19 mm. = 32-38 mm.

- Batten size, spacing and direction

- Batten Size:

- Minimum 2 x board thickness

- T&G: 19-22 mm. = 38-44 mm.

- Other: 16-19 mm. = 32-38 mm.

- Minimum: 38 x 38 mm.

- Batten profile:

- Horizontal boarding vertical batten

- Square

- Vertical boarding horizontal batten fixed to counter-batten

- 15 degree sloping top face to throw off water into ventilation cavity

- Vertical board on board horizontal batten

- 15 degree sloping top face to throw water away from sheathing and breather face

- Metal framing and fasteners

- Avoid different metals in direct contact if possible

- Introduce timber battens between boards and metal framing

- Fix boards with stainless screws to battens

- Fix galvanised framing with galvanized or plated screws to battens

- If unavoidable:

- Galvanized framing and stainless steel fasteners

- Never:

- Stainless framing and galvanized steel fasteners

- Avoid self drilling, self tapping, self countersinking fasteners

- Unprotected mild steel swarf will corrode

- Iron staining of timber and stainless steel

- Electrolytic action between different metals

- See Background and counter-battens

- Insect mesh

- Cavity behind boards can be warm and dry home to insects

- Insects: wasps, woodlice, flies

- Risk factors:

- Urban v rural

- Proximity of trees

- Height above ground

- Etc.

- Guidance:

- TRADA do not advise on need

- Precautionary principle could apply (do it anyway)

- Mesh over openings:

- Bottom and top of cavity

- Close jointed horizontal boarding

- Fix mesh vertically to back wall of cavity

- Fold up and attach to underside of vertical battens

- Spanning between battens

- Close jointed vertical boarding

- Fix mesh vertically to back wall of cavity behind counter-battens

- Fold up and attach to underside of horizontal battens

- Board on board vertical cladding

- Fix mesh to horizontal bottom battens

- Extend out to run continuously across the inner boards

- Sealing gaps behind the outer boards

- Horizontal overlapping boards

- Square and feather edge boards

- Triangular gaps at ends of boards

- Alternate solutions:

- Compressible foam tape

- Between last vertical batten and boards

- Fabric mesh

- Stapled to whole facade battens before boarding

- Open jointed boarding

- Fabric mesh

- Excludes insects

- Stapled to whole facade battens before boarding

- Reduces rain penetration

- Shades cavity from UV light

- Restricts visibility into cavity

- Products

- Perforated metal sheet

- If metal cladding is also used,

- Obtain from installer

- Metal

- Acidic timber

- Stainless steel

- Terne coated stainless steel

- Zinc

- Copper

- Perforation size: __ mm. maximum

- Free air area: __ %

- Fastener:

- Screw if adequate access room

- Same metal as perforated sheet

- Staple if limited access

- Same metal as perforated sheet

- Metal mesh

- Mesh spacing: ____

- Hole size: ____

- Metal

- Acidic timber

- Stainless steel

- Non-acidic timber

- Zinc coated mild steel

- Galvanized chicken wire (small mesh)???

- Non-ferrous metal

- Fastener:

- Screw with large washer if adequate access room

- Same metal as perforated sheet

- Staples if limited access

- Same metal as perforated sheet

- Fabric mesh

- Mesh spacing: ____

- Hole size: ____

- Material:

- UV Resistant plastic mesh

- Nylon

- _____

- Fastener:

- Staples:

- Acidic timber

- Stainless steel

- Non-acidic timber not coated

- Stainless steel

- Non-acidic timber coated

- Zinc coated steel

- Supporting Biodiversity:

- Occupation v Infestation

- What is the consequential risk of occupation?

- Can we encourage without risk?

- Bats?

- Bat droppings and urine on outer face of insulation

- Suits hygroscopic insulation

- Dense cellulose fibre

- Bat droppings and urine on outer face of breather membrane

- Used with open surface hydrophobic insulation

- Moisture resistant vapour permeable membrane

- Paper may not be suitable

- Polymeric may be acceptable

- Tyvek are working with BCT

- Bat droppings and urine on outer face of breathing sheathing boards

- Suits hygroscopic boards

- Dense cellulose fibre and wood fibre boards

- Entry slots

- Higher level (base of upper floors) may be ideal

- Roots

- Trapped warm air is ideal for maternity roots

- Sunny elevations

- Ventilated spaces are ideal for winter hibernation roosts

- Shaded elevations

- Or should we hang bat boxes on outer face?

- Bees and other pollinators?

- Lone bees

- Drill holes in perimeter battens and horizontal board ends

- Various diameters

- Probably not be deep enough

- Build in bee and insect nest box in panels

- Swarms

- Probably discourage

- Avoid honeycomb building inside construction

- Encourage separate weather-boarded hive construction (mobile)

- Or build hives on apex of roofs (not collecting honey)

- Spiders?

- Insect mesh will exclude some and permit others

- But excluding insects will deny them food

- Birds?

- Permitted behind cladding by poor detailing or unfinished work

- House martins

- Fix manufactured nests to cladding below eaves

- Other bird boxes

- Fix to cladding out of reach of cats

- Background

- Solid

- Counter battens to provide ventilation zone

- Battens to accommodate tolerances

- Rainscreen Insulation & DPM

- Insulation and breather membrane or board

- Breathing Sheathing Board

- Airtightness layer

- Spaced

- External walls

- Studs and insulation

- Avoid if possible creates cold bridge through insulation

- Decrement in timber: impact on infrared survey?

- Cold bridge analysis: Psi values

- 400 mm. thick walls

- 400 mm. timber stud and 400 mm. insulation

- psi negligible

- (but metal stud would remain a big problem)

- Studs, insulation and sheathing board

- Sheathing board with insulating properties will reduce cold bridge effect

- External insulation covering the studs wraps up the cold bridges

- Dense cellulose fibre boards

- 2 layer studs and cross battens with insulation in both layers

- Cold bridge minimisation

- 400 mm. thick over all

- Psi value minimised further

- Breather membrane

- Essential to prevent warm air being drawn out of insulation into ventilation space and blown away

- Breathing sheathing board

- Essential to prevent warm air being drawn out of insulation into ventilation space and blown away

- May be essential to hold the insulation in place

- Can have racking strength to add to wall stability

- Can provide additional or substantial thermal insulation for the wall

- Breathing wall construction

- Internal lining

- airtightness layers

- Studs

- Thermal insulation: Hygroscopic with decrement property

- Dense cellulose fibre

- Breathing sheathing board

- Battens

- Weatherboarding

- Pitched roof

- Rafters, eaves & verge framing

- Rafters and boarding (Scottish practice)

- Counter-battens and battens essential

- BRE confirmed that breathing roof construction is also possible

- Rafters and insulation between

- Avoid if possible creates cold bridge through insulation

- Decrement in timber: impact on infrared survey?

- Cold bridge analysis: Psi values

- 400 mm. thick roof

- 400 mm. timber rafters and 400 mm. insulation

- psi negligible

- (but metal rafter would remain a big problem)

- Internal ceiling

- Ceiling joists with thermal insulation

- Ceiling Joist, thermal insulation and board

- Ideally a breather membrane is used over

- Ceiling to flat roof

- Decrement insulation important

- Thermal mass important

- Ceiling to pitched roof with attic space

- Decrement insulation important

- Thermal mass important

- Ceiling to pitched roof with sloping ceiling

- Decrement insulation important

- Thermal mass important

- Ceiling to room in a roof

- At eaves (beyond room)

- Insulated

- Decrement insulation important

- Thermal mass

- Below room

- Insulated

- Decrement less important

- Thermal mass less important

- Floor

- Suspended ground floor

- Suspended upper floor

- Suspended floor over external passage/carport/garage

- Floor joists

- Floor joists and soffit boards

- Rainscreen framing

- See Metal flashings for corrosion issues

- See batten, metal framing and fastenings for corrosion issues

- Access panels and doors

- To service risers

- Water, Gas, Electricity, Telephone, Broadband, Satellite

- RWP, RWHP, SW&VP

- Meters: Electric, Gas, Water

- Gas ventilation issue and Gas Regs.

- Water stop valves, drain cock, outdoor taps,

- Gulley below (low risk of sewer gas)

- Easy replacement areas

- Eaves abutting gable

- Rainwater gutter persistent overflow risk area

- Splash zone

- Detail Design

- General

- Meet service life with minimal maintenance

- 1st line of defence: Design to reduce risk

- 2nd line of defence: Durable – sapwood or + preservatives

- Control of moisture

- Generally

- Always assume rain-screen principle

- Cladding largely protects membrane from wind, rain, daylight and sunlight

- Amount of rain penetration depends upon design of cladding

- Open jointing more rain penetration

- Overlapping less rain penetration

- Open cavity should always be provided

- Drain any moisture penetration

- Ventilate to dissipate any internally generated vapour

- Maintain equal moisture content in both faces of boarding

- Avoid distortions

- Minimum 19 mm. wide

- Usually dictated by the batten size (minimum 38 x 38 mm.)

- Minimum 15 mm. at flashings

- Maintain moisture content (MC) below 22%

- No risk of Fungal attack (UK)

- Little risk of Insect attack (UK)

- Risk of Termite attack (Not UK)

- Wetting to higher than 22% will not instigate decay

- Sustained exposure above 22% increases risk of attack

- UK typical ambient humidity and direct exposure to rain unprotected externally

- Not raise MC above 20%

- BS 1186:Part 3 suggests 19%

- Climate change increase?

- Principles

- Avoid contact with porous surfaces

- Avoid contact with wetted non-porous surfaces

- Prevent wood from absorbing moisture

- Particularly the absorbent end grain

- Waterproof membranes or air gaps required

- Protect top edges of vertical boards

- Ventilate bottom edges of vertical boards: 15 mm.

- Ventilate side edges of horizontal boards: 8 – 10 mm.

- Ventilate bottom ends of diagonal boards: 12 mm.

- Sloping flashings to splash away from board ends

- Avoid sealants

- Backgrounds

- Masonry background

- Waterproof membrane not needed

- Other backgrounds

- Waterproof membrane behind battening

- Bases

- 15 mm. clearance above flashings

- Abutments

- 8 – 10 mm. clearance

- 12 mm. clearance from diagonal boarding

- Ensure water runoff cannot enter behind this joint

- Overhangs

- Generally

- Largely protect walls from direct wetting

- Wind driven rain gets everywhere

- Extend the life of surface finishes

- Not affect the durability of the wood

- Unfinished

- Will slow or prevent natural weathering and bleaching

- Result in uneven colouring between shaded and unshaded

- Horizontal surfaces

- Ground, pavement, flat roofs, decking, etc.

- Smooth surface splash higher

- Irregular large gravels disperse splashes

- Water can sit on surface

- Consider permeable surface

- Indirect wetting from splashing

- Greater wetting of lower boards

- Deterioration of surface finishes

- Possible algal growth

- 200-250 mm. clearance advisable

- Allowing for moisture movement (MM)

- General

- Organic material: Moisture Content (MC) varies with environmental conditions

- MC varies:

- Maximum 22% North face winter

- Minimum 10% South face summer

- Higher and lower % are occasionally recorded

- Seasonal variation on one face varies: 6-8%

- Change in moisture content won’t affect strength or durability

- Avoid restraining fixings or tight jointing

- Risk of splitting cupping or bowing

- Excessive moisture movement: T&G can disengage

- May compromise the fixing to the building

- Design to accommodate MM Moisture Movement

- Design in allowances for MM Moisture Movement

- Match MC in use to MC at construction

- UK normal MC range: 12% – 20%

- BS 1186:Part 3 suggests: 13% – 19%

- Aim to obtain timber of 16% mean MC

- Aim to fix timber at __% mean MC

- Design joints to accommodate shrinkage and swelling

- Generally

- Limit board widths to 150 mm. to limit variation in size

- Especially if used Green

- Overlapping

- Overlapping more tolerant and remain watertight

- Open joint

- Open joints more tolerant remain watertight

- Rebated

- Rebated less tolerant and may not remain watertight

- T&G Tongue and Groove boarding

- Limit board widths to preferably 100 mm. maximum 125 mm.

- Tongue uppermost

- T&G less tolerant and may not remain watertight

- Movement in T&G boards can make assembly difficult

- T&G boards movement can lead to tongue splitting off

- Only kiln dried to recommended MC should be used

- Fixing and fasteners to accommodate moisture movement

- Board Widths

- Below 100 mm. single fixed

- Reduce batten spacing

- Up to 100 mm. single fixed

- Shrinkage either side of fastener

- Over 100 mm. double fixing to help them stay flat

- Stresses between fasteners

- Changes in shape

- Moisture content variations

- Natural tendency

- Predictable

- Turn to advantage

- Section cut from tree

- side nearest the heart of the tree expands relatively (heart side)

- side furthest from the heart side shrinks relatively

- edges cup away from the heart side

- Arrange for joints between board to tighten against each other

- Most boards:

- Heart side to face outward when section installed

- Board on board

- Inner board

- Heart side inwards to face building

- Outer board

- Heart side outwards to face away

- Quarter sawn boards have least risk of changing shape

- Uneconomical to use quarter sawn throughout

- Cladding support: battens and counter-battens

- Battens to which boards are fixed

- Battens usually dictate the ventilation zone depth

- (minimum 19 mm.)

- Vertical cladding, Horizontal Battens Size:

- Dictated by board fastener and board thickness

- Nails

- Nails normally driven just below the surface

- allow for timber shrinkage

- avoiding nail becoming proud of surface

- Nails 20 mm. from end of board

- Nails 15 mm. from edge of board

- Spacing: batten spacing dictates.

- Small head or siding nails can pull through soft WRC

- Larger heads recommended for WRC

- Standard Round wire nails:

- 2.5 x thickness of board

- T&G: 19-22 mm. = 48-55 mm.

- Other: 16-19 mm. = 40-48 mm.

- Annular ring-shank nails

- Improved holding power

- 2 x thickness of board

- T&G: 19-22 mm. = 38-44 mm.

- Other: 16-19 mm. = 32-38 mm.

- Pneumatically driven nails

- D shaped heads may not be visually acceptable

- Virtually headless pins are not recommended

- Screws:

- Minimum 2 x thickness of board

- T&G: 19-22 mm. = 38-44 mm.

- Other: 16-19 mm. = 32-38 mm.

- Batten Size:

- Minimum 2 x board thickness

- T&G: 19-22 mm. = 38-44 mm.

- Other: 16-19 mm. = 32-38 mm.

- Minimum: 38 x 38 mm.

- Batten profile:

- Horizontal boarding vertical batten

- Square

- Vertical boarding horizontal batten fixed to counter-batten

- 15 degree sloping top face to throw off water into ventilation cavity

- Vertical board on board horizontal batten

- 15 degree sloping top face to throw water away from sheathing and breather face

- Counter-battens, studs, joists or rafters

- Spacing of nails or screws dictated by this spacing

- Usually fixed vertically or running down slope

- Reduced centres

- Helps reduce tendency for boards to twist, bow or cup

- Green timber cladding

- Centres reduced to 400 mm. (maximum 500 mm.)

- Narrow boards (less than 100 mm.)

- Centres reduced to 400 mm.

- Vertical or horizontal boards

- Not greater than 600 mm. centres

- Diagonal boards

- Vertical or horizontal battens

- Not greater than 400 mm.

- Diagonal battens

- Not greater than 600 mm.

- Counter-batten size:

- To maintain 19 mm. ventilation zone

- Vertical boarding:

- Counter-batten size: 16 x __ mm.

- Perimeter battens

- Omit or reduce thickness of any perimeter battens (top and bottom of horizontal boarding)

- Maintain 19 mm. ventilation zone

- Resource Efficiency

- Reduce waste in design

- Obtain knowledge of what is available: width and length

- Design with available width and length in mind

- Choose species according to preferred design width and length

- Design for Demountability

- Fasteners

- Screws

- Accessible heads

- Corrosion resistant to enable unscrewing later

- Nails: Avoid

- Metal

- Future reuse as screw essential

- Corrosion resistant

- Austenitic stainless steel

- Grade: 304 or 316 (marine grade)

- Corrosion resistant finish

- Susceptible to damage when driving

- Reclaim for reuse

- Care with fixings avoid damaging boards

- Use screwdriver in reverse to remove screws

- Assemble multiple pallets to support lengths

- Strapping to secure, timber strips to protect

- Waste issues

- Hazardous waste (treated or coated)

- Active Virgin timber

- Compostable waste (perishable species)

- Mixed waste (treated or coated)

- Samples & Mock-ups

- Samples

- Require sufficient samples prior to purchase

- Purpose

- Agree visual quality of profile

- Check size of section

- Agree visual quality of timber

- Knots

- Sapwood

- Colour range

- Agree finish: surface texture, transparency, colours, gloss level

- Timing

- In advance of purchase deadline to meet programme

- Programme may include mock-up construction and approval process

- Mock-ups

- Position:

- as if in real building

- Height, distance and viewing angles

- for accurate judgement

- in the real building

- if acceptable, as part of the final works

- Large enough to include:

- Long lengths of timber, butt joints

- Background build-up, framing,

- boundaries, edges

- Internal and external changes of direction,

- Openings,

- Changes in design

- Purpose

- Check interfaces with other trades

- Ensure required quality can be achieved

- Agree acceptable quality if different

- Timing

- In advance of purchase deadline to meet programme

- Drawings

- Standard Details

- Show the proposed construction details (fixed)

- Principle Details

- Show the ideal details (fixed)

- but offer designers some choices about:

- size, profile, species, finishes (unfixed)

- Materials handling and storage

- Materials can be spoiled and repairs may be impossible or unacceptable

- Wasting materials is unacceptable practice

- Risks

- Exposure to excessive wetting

- Exposure to mud splashes

- Exposure to cement slurry splashes

- Damage by foot traffic boot marks

- Damage by impact

- Protection

- Protection is essential in transportation, storage and once installed

- Storage

- Avoid over tight banding

- Protect edges of boards from damage

- T&G vulnerable

- On solid flat (shallow slope to self drain) surface

- Dry concrete suitable

- Lime stabilised soil suitable

- Avoid soil base (mud splashes)

- Away from traffic flows (mud splashes)

- On battens or pallets to prevent contact with soil and ground water

- Batten spacing to prevent deflection of stack or individual boards

- Undercover and ventilate

- Exclude moisture but encourage moisture egress

- Green timber

- Consider stacking with sticks between layers

- Ventilation to reduce moisture content

- Sticks must be clean and dry to avoid stick marking

- Unfinished installation boards

- Special care to keep clean and dry and free from soil and cement splashes and damage

- Sawn finishes impossible to sand to remove marks

- Natural weathering of any marks: long slow process

- Prefinished boards or panels

- Avoid damage of finish

- Avoid touching up as it is difficult to do well

- Colour matching

- Gloss level matching

- Blending in

- Loss of durability compared with factory applied

- Installation

- Moisture content

- At time of installation is important

- As specified

- Check and record immediately before installation

- It may be different to when delivered

- Condemn timber for use on the project if MC drops by _ %

- Heartside arrangement

- Normal boarding

- Symmetrically profiled boards

- If growth rings are visible in cross section of boards

- Ensure heartside is on outer face

- Board on board

- Inner board heartside to face inwards to wall

- Outer board heartside to face outward

- Care with kiln dried and sawn timber this may reverse requirements

- Allow for moisture movement: Expansion

- 2 mm. gap for up to 150 mm. wide T&G

- What gap for larger?

- Allow for moisture movement: Shrinkage

- Green timber will shrink on drying

- Provide less gap

- T&G not suitable for Green Timber

- Open joint setting out should make joints narrower so they are correct once dry

- X mm. per xxx mm.

- Determined by calculation

- Butt jointing boards

- Unfinished timber: 5 mm. gap

- Coated timber: 8 mm. gap

- Always occur on doubled battens

- Random length: add additional batten, length: ≥ 3 x board width