GBE > Encyclopaedia > Files > Method Statements > G#14281

LoftZone StoreFloor Method Statement

LoftZone StoreFloor Method Statement

About:

Method Statement Schedule: See below

© GBE NGS ASWS Brian Murphy aka BrianSpecMan

28th December 2016

LoftZone StoreFloor Method Statement

Images:

LoftZone StoreFloor Method Statement

Page 1 of 2

Page 1 of 2

© GBE NGS ASWS Brian Murphy aka BrianSpecMan

28th December 2016

LoftZone StoreFloor Method Statement

See Also:

GBE Collaborative Services

- GBE Product Data Collection

- GBE Method Statement (Collaborate) G#12677

- GBE Method Statements (Navigation) G#490 N#503

- GBE Robust Specification G#541 N#561

GBE Products

- LoftZone StoreFloor G#23287

GBE Method Statements

© GBE NGS ASWS Brian Murphy aka BrianSpecMan

28th December 2016

LoftZone StoreFloor Method Statement

Schedule:

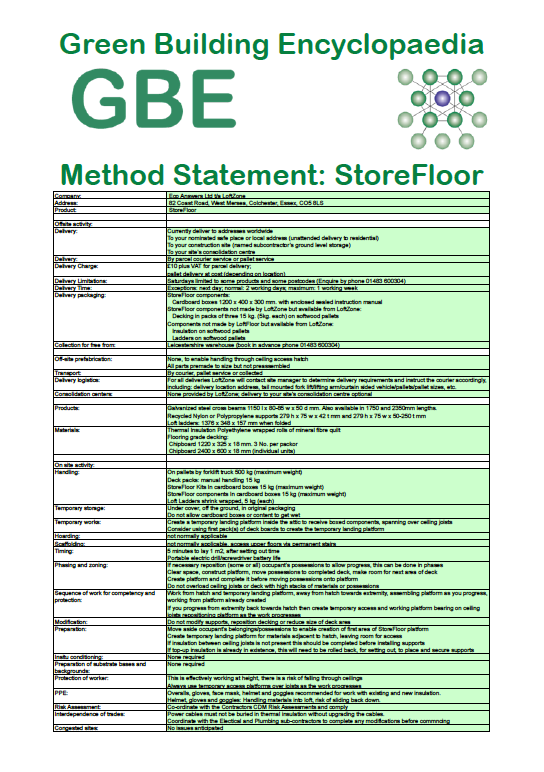

| Method Statement: StoreFloor | |

| Company: | Eco Answers Ltd t/a LoftZone |

| Address: | 82 Coast Road, West Mersea, Colchester, Essex, CO5 8LS |

| Product: | StoreFloor |

| Offsite activity: | |

| Delivery: | Currently deliver to addresses worldwide To your nominated safe place or local address (unattended delivery to residential) To your construction site (named subcontractor’s ground level storage) To your site’s consolidation centre |

| Delivery: | By parcel courier service or pallet service |

| Delivery Charge: | £10 plus VAT for parcel delivery; pallet delivery at cost (depending on location) |

| Delivery Limitations: | Saturdays limited to some products and some postcodes (Enquire by phone 01483 600304) |

| Delivery Time: | Exceptions: next day; normal: 2 working days; maximum: 1 working week |

| Delivery packaging: | StoreFloor components: Cardboard boxes 1200 x 400 x 300 mm. with enclosed sealed instruction manual StoreFloor components not made by LoftZone but available from LoftZone: Decking in packs of three 15 kg. (5kg. each) on softwood pallets Components not made by LoftFloor but available from LoftZone: Insulation on softwood pallets Ladders on softwood pallets |

| Collection for free from: | Leicestershire warehouse (book in advance phone 01483 600304) |

| 0 | |

| Off-site prefabrication: | None, to enable handling through ceiling access hatch All parts premade to size but not preassembled |

| Transport: | By courier, pallet service or collected |

| Delivery logistics: | For all deliveries LoftZone will contact site manager to determine delivery requirements and instruct the courier accordingly, including: delivery location address, tail mounted fork lift/lifting arm/curtain sided vehicle/pallets/pallet sizes, etc. |

| Consolidation centers: | None provided by LoftZone; delivery to your site’s consolidation centre optional |

| 0 | |

| Products: | Galvanized steel cross beams 1150 l x 80-85 w x 50 d mm. Also available in 1750 and 2350mm lengths. Recycled Nylon or Polypropylene supports 279 h x 75 w x 42 t mm and 279 h x 75 w x 50-250 t mm Loft ladders: 1376 x 348 x 157 mm when folded |

| Materials: | Thermal Insulation Polyethylene wrapped rolls of mineral fibre quilt Flooring grade decking: Chipboard 1220 x 325 x 18 mm. 3 No. per packor Chipboard 2400 x 600 x 18 mm (individual units) |

| 0 | |

| On site activity: | 0 |

| Handling: | On pallets by forklift truck 500 kg (maximum weight) Deck packs: manual handling 15 kg StoreFloor Kits In cardboard boxes 15 kg (maximum weight) StoreFloor components In cardboard boxes 15 kg (maximum weight) Loft Ladders shrink wrapped, 5 kg (each) |

| Temporary storage: | Under cover, off the ground, in original packaging Do not allow cardboard boxes or content to get wet |

| Temporary works: | Create a temporary landing platform inside the attic to receive boxed components, spanning over ceiling joists Consider using first pack(s) of deck boards to create the temporary landing platform |

| Hoarding: | not normally applicable |

| Scaffolding: | not normally applicable, access upper floors via permanent stairs |

| Timing: | 5 minutes to lay 1 m2, after setting out time Portable electric drill/screwdriver battery life |

| Phasing and zoning: | If necessary reposition (some or all) occupant’s possessions to allow progress, this can be done in phases Clear space, construct platform, move possessions to completed deck, make room for next area of deck Create platform and complete it before moving possessions onto platform Do not overload ceiling joists or deck with high stacks of materials or possessions |

| Sequence of work for competency and protection: | Work from hatch and temporary landing platform, away from hatch towards extremity, assembling platform as you progress, working from platform already created If you progress from extremity back towards hatch then create temporary access and working platform bearing on ceiling joists repositioning platform as the work progresses |

| Modification: | Do not modify supports, reposition decking or reduce size of deck area |

| Preparation: | Move aside occupant’s belongings/possessions to enable creation of first area of StoreFloor platform Create temporary landing platform for materials adjacent to hatch, leaving room for access If insulation between ceiling joists is not present this should be completed before installing supports If top-up insulation is already in existence, this will need to be rolled back, for setting out, to place and secure supports |

| Insitu conditioning: | None required |

| Preparation of substrate bases and backgrounds: | None required |

| Protection of worker: | This is effectively working at height, there is a risk of falling through ceilings Always use temporary access platforms over joists as the work progresses |

| PPE: | Overalls, gloves, face mask, helmet and goggles recommended for work with existing and new insulation. Helmet, gloves and goggles: Handling materials into loft, risk of sliding back down. Helmet: Risk of head impacts in timber roof. Knee protection: working on knees Consider safety harnesses and landyard secured to roof timbers for working at height |

| Risk Assessment: | Co-ordinate with the Contractors CDM Risk Assessments and comply |

| Interdependence of trades: | Power cables must not be buried in thermal insulation without upgrading the cables. Coordinate with the Electrical and Plumbing sub-contractors to complete any modifications before commencing Recessed ceiling lighting may need access for fitting and maintaining before and after installation |

| Congested sites: | No issues anticipated |

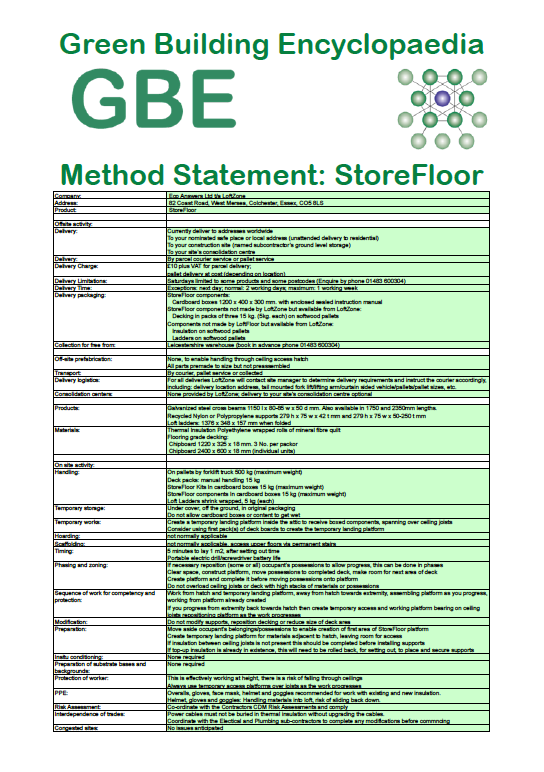

| Congested working: | Only if electricians or plumbers are not complete before commencing StoreFloor; coordinate sequencing and timing to minimise hindrance |

| Methods of pre-assembly: | Not applicable, to enable handling through ceiling attic hatch |

| Offering up: | Not applicable |

| Craning: | Not anticipated, use hoist and fork lift trolley or truck for pallets |

| Sequence of assembly: | Follow instruction manual or instruction video Previous trades, preparation, setting out, supports, screws, beams, screws, decks, screws, possessions |

| Final piece assembly: | Cross-beams can slide over supports to negotiate adjacent obstructions Avoid staggered boarding to minimise limitations for future access to services |

| Safe access for maintenance and removal or replacement of damaged pieces: | The deck provides access, if required roll back insulation and use temporary platform on ceiling joists |

| Staff: | StoreFloor is available via an installer network (Enquire by phone 01483 600304) |

| Skills: | StoreFloor is suitable for Do-it-yourself |

| Accessories: | Screws ‘Spax’ or equivalent, Wood Screws 4 x 40 mm No. 8 x 1.5″ countersunk head, and self-drill into steel Top up thermal insulation Decking boards |

| Equipment for installation: | Retractable measuring tape String, chalk line or laser and pencil Portable battery drill/screwdriver with countersink and drill bits and spare battery on larger jobs |

| Protection of installed parts: | None needed Immediate use anticipated with transfer of belongings/possession onto deck as work progresses |

| Access after protection: | Use deck, if permitted to use permanent installation during construction |

| Modification of protection: | Not applicable |

| Warranty maintenance: | None available |

| Final removal of protection: | Not applicable |

| 0 | |

| In retrofit: | 0 |

| Logistics of decanting possessions, storage and reinstatement upon completion: | No decanting necessary, belongings/possessions relocated onto deck as the work progresses |

| Decanting of occupants, temporary accommodation and returning to homes: | Not required but keep rooms below clear of occupants in case of accidents (falling through ceiling) |

| 0 | |

| Demolition work: | 0 |

| Soft strip, deconstruction, reclaim: | Unscrew all decking, cross-beams and supports, reclaim for reuse Protect for handling, transport and storage ready for reuse |

| Hazardous removal: | Not applicable |

| Demolition: | Not applicable |

| Reuse: | Ensure decking panels do not get wet, |

| Recycling on or off site: | Not applicable |

| 0 | |

| Excess to requirements: | Return to stock |

| Return to stock: | Full refund for returned to warehouse within 28 days (phone in advance 01483 600304) |

| Offcut take back: | Not available |

| Packaging waste return to producer: | Not available |

| Instruction manual return to producer: | Not available |

| Diversion from landfill: | Normal site waste management plan SWMP activity |

| Processing under producer responsibilities: | Not available |

| Waste minimization and management: | Plan ahead, do not over order, |

| Offcuts: | Avoid obstructions, keep modular, avoid staggering, avoid cutting; (offcuts into segregated waste containers) |

| Waste handling on site: | Segregate pallets, cardboard, plastics and metal (whole plastics and metal items return to stock) |

| Waste removal off site: | Not applicable |

| European Waste Catalogue: | 15 01 01 paper and cardboard packaging 17 02 01 wood (decking and pallets) 17 02 03 plastic (supports) 17 04 04 zinc (galvanizing) 17 04 05 iron and steel (cross-beams) 17 04 07 mixed metals (galvanized steel cross-beams, screws) 17 06 INSULATION MATERIALS AND ASBESTOS-CONTAINING CONSTRUCTION MATERIALS 17 06 01* insulation materials containing asbestos (not applicable unless existing) 17 06 03* other insulation materials consisting of or containing DS (not applicable unless existing) 17 06 04 insulation materials other than those mentioned in 17 06 01 and 17 06 03 (thermal insulation) 17 08 GYPSUM-BASED CONSTRUCTION MATERIALS 17 08 01* gypsum-based construction materials contaminated with DS (not applicable) 17 08 02 gypsum-based construction materials other than those mentioned in 17 08 01 (in case of accidents) |

| End of Life Opportunities for reclaim and reuse or recycling and recovery: | Unscrew all components, reclaim, store and make available for reuse |

| Product Passport documentation: | None provided yet Supports are moulded with company and product name inscribed with URL Cross-beams are dot matrix printed with the company name and CE mark |

| Value Engineering Opportunities: | Multi-functional: Partially removes installation team from ceiling and reduces risks of falls through ceiling Protection of thermal insulation from compression and loss of performance in winter and summer Storage deck for belongings/possessions increasing building storage capacity Avoids the need to decant belongings and posessions from attic space before work commences Access walkway for maintenance of MEP service installations Creates its own work platform for extending the platform |

| Lean Construction: | All parts premade to size but not preassembled Simple, easy to handle, fast to install |

| Specifications: | 0 |

| Products: | K43/224A PRIMARY SUPPORT BRACKETS K43/225A SECONDARY SUPPORT BRACKETS K43/226A CROSS-BEAMS K43/228A LATERAL RESTRAINTS |

| System: | K43/120A RAISED LOFT FLOORING SYSTEM |

| Accessories: | K43/230A PRIMARY INSULATION K43/231A or K43/231B TOP-UP INSULATION K43/232A BLOWN/POURED IN TOP-UP INSULATION K43/240A or K43/241A LOFT FLOOR BOARDS K43/280A FASTENERS |

| Installation: | K43/310 to K43/520 |

| Workmanship: | K43/290 to K43/450 |

| Waste: | K43/450A to K43/460A |

| Facilities Management: | K43/610 |

| End of Life: | K43/710 |

| Author initials: | BRM |

| Method Statement date: (DD/MM/YYYY) | 14/10/2016 – 16/12/2016 |

© GBE NGS ASWS Brian Murphy aka BrianSpecMan

28th December 2016