GBE L15 External Solar Shading (Outline)

GBE > Encyclopaedia > Code > Outline > G#41109

Legend:

- Outlines are the essence of the topic in a hierarchical order

- They could become the core of an Expert System or Design and Decision Tool

- The colour coding in the word file highlights:

- Green Environmental Options

- Violet Normal Practice

- Red Missing information

- (in the book it was extracted from)

Green: Consider for GBE

- E.g. of approach:

- FSC only

- Preservative treatment: Avoid if possible

Blue: for TRADA but not GBE

- FSC and PEFC

- Treated softwood

- Painted softwood

Violet: Avoid not for GBE

- Treated softwood

- Nails make demountability less successful

Red: Pending information by me or clarification from Patrick Hislop

Outline:

GBE L15 External Solar Shading Outline

- Outline of timber constructions in readiness for an expert system and specifications

- Extracting the essence from TRADA Weatherboarding publications by Patrick Hislop

L15 External Solar Shading Outline

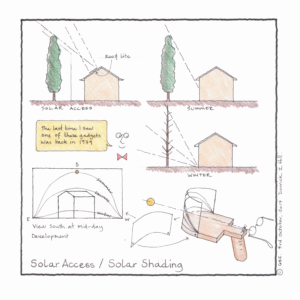

Performance requirements

- Maximise view/restrict viewing angles

- Minimise sunlight penetration (avoiding glare and overheating internally)

- Maximise daylight penetration (reduce use of artificial lighting)

- Maximise reflection of daylight off surfaces

- Minimise reflection of sunlight from surfaces

- Maximise Ultra violet light absorption upon reflection from surfaces

- Resist wind load and uplift

- Not generate wind noise or rattling

- Resist defection and creep

- Durability

- Security screen

- May for maintenance access walkways

- Support loadings

Arrangements

- Flush with wall cladding

- Vertical integral and flush with cladding in front of window

- Vertical in front of window

- Vertical projecting at side of window

- Vertical spaced from the window

- Vertical surrounding balconies

- Projecting/Horizontal

- Horizontal projecting from window head

- Horizontal projecting from window forming light shelf

- Horizontal above flat rooflight

- Horizontal above balconies and roof terraces

- Projecting/Sloping

- Sloping above sloping rooflight and conservatory roof

- Sloping projecting from window head

- Combination(s) of the above

Design

- Integral/flush with /same detailing as wall cladding

- Rainscreen approach open jointed cladding system

- Alternate boards/battens continue across window

- Alternate boards/battens/blades continue along walls

- Independent

- Panelised

- Unframed

- Framed

- Hardwood framed

- Same durability as blades

- Sub-framed

- Metal frame

- Mild Steel

- Hot dip galvanized

- Sacrificial coating of zinc rich epoxy paint if acidic timber

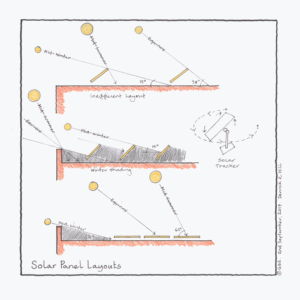

Blade orientation

- Vertical

- In vertical or sloping installation

- Greatest resistance to deflection and creep

- Greatest spanning potential

- Top surface profiled for rainwater runoff

- Drip profile at base

- Sloping (normal to the sun’s rays)

- In vertical installation

- Offers some resistance to deflection and creep

- Design to overcome deflection and creep

- Seek to obtain stiffness from supports and fastenings

- Encourages rainwater runoff, the steeper the better

- Drip profile at base

- Horizontal

- Poorest spanning potential

- Design to overcome deflection and creep

- Seek to obtain stiffness from supports and fastenings

- Risk of rainwater standing on top

- Risk of staining

- Risk of runoff and condensation on bottom

- Risk of staining

- Consider self weight and wind loading

Shading array dimensions

- To exclude sun at 56 degrees above horizontal (UK summer)

- To permit sun at 10 degrees above horizontal (UK winter)

- To exclude/permit sunlight at other angles (to suit brief)

Blade Size and Spacing

- Narrow blades/battens/boards

- Closer spacing to exclude sun

Wide blades/battens/boards

- Wider spacing to exclude the sun

- Spacing to encourage consistent bleaching of unfinished timber

Species

- Generally

- Strong stiff species for spanning

- Douglas Fir

- Preservative treated

- European Larch

- Low self weight if horizontal (shallow slope)

- Western Red Cedar

- Strength stiffness and low moisture movement

- For long spans between supports

- Durable Tropical hardwoods

- Durability class 1 or 2

- Sapwood removed

- Unfinished

- Durability class 3 4 or 5

- Preservative treated

- Softwood

- Local

- Native

- European Larch (Larix deciduas)

- care with Sustainable Certification

- Class 3 moderately durable

- Small movement

- Less dense, strong and knot-free

- Also suitable for shingles and shakes

- Non-native

- Western Red Cedar (Thuja plicata)

- UK grown less durable than North American class 2

- Remove sapwood

- Small knots common in UK grown

- Small movement

- Lightweight

- BS 8417: 60 year service life

- Resistant to preservative treatment

- High tannin content corrosive: protect porous and steel or iron materials below

- Soft and brittle:

- Avoid applications prone to mechanical damage: low level

- Solar shading with single fixings subject to rotation torsion

- Avoid unfinished where high levels of pollution present (traffic and industrial processes)

- Also suitable for shingles and shakes

- Douglas Fir (Pseudotsuga menziesii)

- (UK grown less durable Class 3-4 moderately to slightly durable than North American Class 3)

- Resistant to treatment

- Can be left unfinished to fade

- Requires preservative treatment

- European Larch (Larix deciduas)

- care with Sustainable Certification

- Class 3 moderately durable

- Small movement

- Also suitable for shingles and shakes

Hardwood

Fixings/Framing

- Acidic timber

- Acidic timbers need stainless steel fasteners

- Wood to wood

- Wood to galvanized

- Frame often galvanized mild steel

- Predrill mild steel and hot dip galvanized

- Austenitic stainless steel and galvanized steel are incompatible

- but large amounts of galvanized steel can cope with small amounts of stainless steel

- Do not use self drilling self tapping stainless fasteners into galvanized

- Isolate metals with grommets, sleeves and washers

- Remove all metal swarf to avoid tannin corrosion and staining

- Non acidic timbers

- Non-acidic timbers externally need corrosion resistant fasteners

- stainless steel fasteners (screws bolts washers)

- Wood to wood

- Frame often galvanized mild steel

- Predrill mild steel and then hot dip galvanized

- Galvanized steel fasteners (nuts bolts washers)

- Wood to galvanized

- Do not use self drilling self tapping fasteners into galvanized

- Fastenings

Generally

- Strength needed at supports

- Minimum 2 fasteners to overcome wind loading twisting rotation stresses

- Minimum 2 fasteners to overcome moisture movement shrinkage

- Minimum 2 fasteners to overcome drying distortion in green timbers

- Low density timber

- Prone to early failure

- Species:

- Western Red Cedar

- Heat treated timbers

- High density timbers

- Still use two fasteners

- Overcome tendency to distortion in drying shrinkage

- Panelisation

- Offsite preassembly

- Rigid panels for handling

- Fix back to structure at larger centres

- Notched members receive notched blades

- Helps overcome distortion

- Reduce span of blades

- Fixing

- Screwed and glued

- Gluing may help prevent rattling

Revisions

| Revision No. | Description | Author | Date | Checked by: |

| A00 | Created issued to SP to start process rolling | BRM | 02/05/2008 | |

| A01 | Revised refinement and development using TRADA Cladding guide 2nd edition (incomplete) | BRM | 06/05/2008

– 17/05/2008 |

|

| A02 | Revised refinement and development using TRADA Cladding guide 2nd edition (complete)

Reorganised content list, H21 and Added K42 |

BRM | 26/05/2008 | |

| A03 | Continue to add to scope and to H21 (complete) | BRM | 12/06/2008

– 19/06/2008 |

|

| A04

|

K13 (internal) copied to H20 (external) new

K13 similar to H20 pending editing Specification clauses now in a separate file Minor refinements Issue to Sandy |

BRM | 26/06/2008

– 03/07/2008 & 31/10/2008 |

|

| A05 | Rename GBE H21 Outline from TRADA Book.docx | BRM | 26/02/2016 | |

| A05 | Replace GreenSpec with GBE | BRM | 26/02/2016 | |

| A05 | A few tweaks for TDUK issue (H21 only) | BRM | 10/07/2023 | |

| A05 | Issue to MM at TDUK | BRM | 10/07/2023 | |

| A06 | Split the file L15 from H21 | BRM | 21/08/2023 |

© GBE GBC GRC GBL NGS ASWS Brian Murphy aka BrianSpecMan ****

10th November 2023

Images:

Leicester Curve Theatre Curtain walling External Solar Shading

British Library Euston Science Reference Information Service Clerestorey Window Solar Shading

British Library Euston Rare Books Reading Room Rooflight Solar Shading

Chiswick Park Offices Solar Shading and Stairs

GBE CPD Overheating

Chiswick Park Whole Building Solar Shading DCP_5731

Blue Fin Building Southwark,

100% glass facade with randomly positioned and angled blinkers on the south facade

At best 25% solar shading 75% glass on show to the sun DCP_4121

GBE L15 External Solar Shading (Outline)

Hospital Euston Road/Tottenham Court Road: Fritting and tiny solar shading blades on all 4 elevations DCP_1280

Blue fin Building Southwark: Solar blinkers effective in the morning and the evening but not mid day DCP_4122

Portcullis House London, Solar shading over windows, oriels, dormers, on South and West facades IMG_2462

Horizontal Solar Shading and Vertical Blinkers on Western Elevation and none on the North DCP_5937

Undulating surface helps heat to escape facade but solar shading might push it back again DCP_6855

UEA Enterprise Centre Entrance Courtyard North Wing South Elevation, Solar shading, panel cladding, Ventilation Louvres, Windows, Flint Filtre Drain Trench landscape

© GBE GBC GRC GBL NGS ASWS Brian Murphy aka BrianSpecMan ****

10th November 2023

See Also:

GBE Outline

- GBE H21 Timber Weatherboarding (Outline) G#10281

- GBE H64 Timber Shingles Shakes (Outline) G#38895

- GBE L15 External Solar Shading (Outline) G#41109 The page

GBE Books

- Shading for Housing (Book) G#_____

GBE Checklist

- Decent Homes (Checklist) G#1571 N#1507

- Refurbishment Decent Homes (Checklist) G#1253 N#1252

- Green Deal Refurbishment (Checklist) G#730 N#752

- Other issues (Checklist) G#1570 N#1506

- GBE New Build Checklist (Navigation) G#606 N#627

- L10 Windows (Checklist) G#1605 N#1534

- L10 Windows Rooflights Screens Louvres (Checklist) G#1604 N#1533

GBE Brain Dumps

- EcoHomes What does the future look like (Brain Dump) G#40732

- How to Design Sustainably (Brain Dump) G#40730

- MMC Modern Methods of Construction (Brain Dump) G#39443

- Greening Offices Biophilia (Brain Dump) G#39346

- Building Performance Aspects (Brain Dump) G#21255

- Product Data Golden Thread (Brian Dump) G#39241

GBE Brainstorms

- Sommerfield One Off House (Brainstorm) G#760 N#782

GBE CPD

GBE CPD Titles

- A90 Performance Specification (CPD) G#1377 N#1354

- Overheating (CPD) G#15750

- SunSpace WinterGarden Conservatory (CPD) G#294 N#295

- Surveys Tests Analysis (CPD Lecture) G#389 N#390

- Welsh Passivhaus case study (CPD) N#251

- Zero Carbon Development Passive Approach (CPD)

GBE Shop

GBS Robust Specification

GBE Projects: Information

GBE Datasets

GBE Shop

- Timber Species Schedule (Shop) G#10656

GBE 6 Core pages

GBE Suppliers

- FSC Suppliers

GBE Installers

- Company names

GBE Systems

- System Reference: __

GBE Accessories

- Accessory Reference: _

GBE Manufacturer

- Company name

GBE Materials

GBE Collaborative Services

© GBE GBC GRC GBL NGS ASWS Brian Murphy aka BrianSpecMan ****

10th November 2023 – 11th November 2013