About:

Index:

Problems:

- Thermal bridging around windows

- Air leakiness around windows

- (see GBE Robust Specification P14)

- Thermal discomfort due to poor U value windows makes a well insulated building fail to meet expectations

- Excessive heat loss through windows compared to opaque building fabric

- (See U Values to Energy consumption to Carbon GBE Calculator)

Misunderstandings:

- Robust Details do not refer to durable tough details they refer to competent acoustic details that may fall short on other performance requirements.

- A passivhaus window does not automatically perform as well as designed if installed incorrectly or misaligned with the insulation in the wall

Solutions:

- Competent detailing (not necessarily robust details)

- Correct placement of windows in relationship to insulation in surrounding walls

- Passivhaus windows can eliminate cold down drafts and cold feet

- Avoid placing radiators under windows and on inside face of external walls

- Spend us much as you can on high performance windows

Consider:

- ‘Fabric First’ & ‘Build tight – Ventilate right’

- Highest performance windows you can afford,

- to reduce fuel demand (during heating season) over life of building

- Many Scandinavian manufacturers offer high specification at good price,

- not many UK manufacturers can compete, a few exceptions.

- Trickle vents controllable by occupant, visible and easy to use without risk of jamming

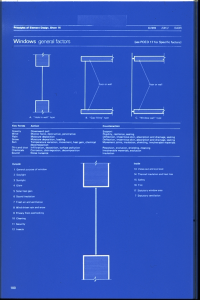

- Internal temperature of glass needs to be as close to the temperature of the wall

- (17-18 degrees C) for thermal comfort

- U values of 0.8 to 0.5 W/m2.K should achieve these temperatures

- Double and Triple glazing

- U Values of 1.0 to 0.5 W/m2.K are achievable

- Use Double Glazed Sealed Units to BS EN 1279-2 and BSI Kitemarked

- Use Low E (Emissivity) glass generally

- (to minimize heat loss by reflecting it back in)

- Use Argon, Pentane or CO2in sealed units

- (but be aware of the high environmental impact: See Bath ICE Database)

- Exclusion of UV light, using PVB interlayer in laminated glass

- (to reduce fading of objects inside)

- Permitting UV Light: for plant and food growing green houses

- Co-ordinate window and door opening with brick sizes and/or blocks modules to minimize cutting waste

- FSC approved timber sources and timber based materials See Z10

- Timber: Hardwood, Heartwood of softwood, Slow grown timber, reclaimed timber

- Uncoated recycled aluminium

- (but no coating reduces component life marginally)

NEW WOOD WINDOWS FROM UK MANUFACTURERS

- Choose local or FSC certified timber.

- Choose High performance windows with manual control trickle vents

- Choose from the British Woodwork Federation BWF’s Timber Window Accreditation TWA Scheme: Manufacturers, Suppliers and Installers.

- http://www.bwf.org.uk

- Get them fully finished in the factory on all faces, but avoid oil paints, choose microporous high build paints or stains

- Consider aluminium sill and bottom beads for durability in the most vulnerable locations.

- Choose BBA Certified and/or BSI Kitemarked windows

- Choose with BSI Kitemark Double Glazed Sealed Units

- Choose Windows with Secure by Design Accreditation

NEW WINDOWS FROM EU MANUFACTURERS

- Scandinavian and east European windows: are usually high performance compared to many UK makes.

Avoid:

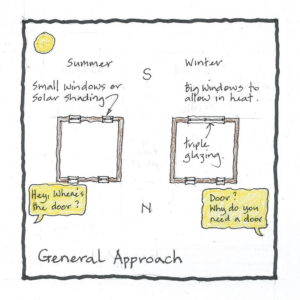

- Excessive glazing on north face (heat loss and thermal discomfort in winter)

- Excessive glazing on any face (heat loss and thermal discomfort in winter)

- Excessive glazing on east and west faces (heat gains in summer unless it is managed and exploited)

- Excessive unshaded glazing on the south face

- (heat gains in summer can be a problem and need external shading)

- (Heat gains in winter should be encouraged)

- Single glazing:

- higher chance of condensation on inner face

- thermal discomfort for occupants

- Double Glazed Sealed Units only offering U Value between 1.0 and 2.0 W/m2.K

- Indonesian & Brazilian Hardwood

- Much is reported to be illegally logged: destroys forests, communities, habitation, biodiversity

- CCA (Copper Chrome Arsenic) Treated softwood, See Z12

- Powder coated aluminium (hazardous residue or emissions when recycled)

- Primed timber windows being installed and then painted insitu, leaving vulnerable absorbent timber against potentially wet masonry.

- Apply full paint scheme to ALL faces in the factory.

- Virgin plastics See Z50

- PVC See Z50

- Give yourself and the fire fighters a better chance of survival in a fire

- Grenfell tower block fire enquiry has highlighted PVC windows and PVC infill as the route for fire in a kitchen to escape to the outside of the tower (moving from floor to floor by other means) and back into the flats above, killing many occupants.

- Some Responsible Social Landlords have had enough bad experience to refuse to use PVC windows.

- Some RSL have maintenance regimes in place to wash PVC windows inside and out every 3 months so they have a chance to check for failing Ironmongery.

- They will also check for pinking or yellowing of the frames.

- Dulux created a paint specifically for painting PVC windows, I wonder why?

- 25 year life is optimistic for PVC windows, Ironmongery fails sooner if not steel reinforced sections.

Minimise:

- Minimise frames and maximise high performance glass in windows to reduce heat loss

- Frameless windows with high performance glass has potential to be best option

- Use of virgin aluminium in window frames

- Use of aluminium frames, despite thermal breaks to minimise condensation, they are not insulating

- Use of PVC in all applications

- Use of preservatives in timber frame windows

- U value of windows by minimising frame area, choosing high performance glazing, use warm edge spacers, insulate the gap between window and wall opening

- Thermal flanking by aligning windows with insulation in surrounding wall or wrapping insulation around jambs to meet the windows

- Thermal bridging through mechanical fixings and fastenings by installing window in plywood box into wall opening

Substitute:

- GRP Pultruded faced composite timber for:

- aluminium faced composite timber window frames

- PVC windows

L10 Windows Rooflights Screens Louvres Checklist

Health:

- Long life powder coated or anodized aluminium in preference to painted metalwork

Wellbeing:

- Don’t ignore the feel good factor of seeing and touching timber

Safety:

Precautionary principle:

L10 Windows Rooflights Screens Louvres Checklist

Resource Efficiency:

Reduce:

- Use of virgin aluminium in window frames

Reclaim:

- Reclaimed wooden windows

- Web Portal: Salvo Ltd.

Reuse:

- Reclaimed windows

- See Historic England & Historic Environment Scotland Research

Repairing Windows:

- Repair PVC windows rather than remove and landfilling them.

Refurbishing Windows

- See C51

- See Refurbishment Checklist L10

Recycle:

- Use recycled aluminium in preference to virgin aluminium, significant reduction in energy consumed and potentially CO2 generated

Recover:

- Do not incinerate:

- PVC windows high risk of Dioxin release to the atmosphere (See Trashed Film/Video)

- Painted wood windows

- Preservative treated wood windows

- Do not burn off coatings on aluminium windows

- Ensure emissions to air are controlled

L10 Windows Rooflights Screens Louvres Checklist

Waste Issues:

- WRAP guide on dismantling PVC windows to segregate waste

Waste Category:

- Window: Mixed waste

- Double glazed sealed units: Mixed waste

- Single glass: Inert

Waste statistics:

Waste minimization:

- Measure the openings accurately and forward the survey information before manufacture

End of Life options:

Hazardous waste & Deleterious Substances:

Design for recycling:

- avoid coatings as they create problematic expensive hazardous waste or emissions when recycling aluminium

- e.g. PPC Polysester Powder Coating and PVF2 Poly Vinyl Fluoride Coating

- Anodising is a chemical oxidation process generating an oxide of aluminium

- Anodised aluminium generates less problematic waste when recycled

- Mill finish is best for recycling but not everybody likes the oxides that form on aluminium

- Mill finish aluminium may have a marginally shorter life than coated aluminium

Appropriateness:

- Passivhaus windows in Passivhaus buildings

- Insulated, airtight weather resistant gap filling between window and surround

- Airtightness membranes designed for window perimeters and adjacent materials

- See GBS Robust Specification P14

Competence:

- Align windows with the insulation in the surrounding wall or link them if they do not align

- Thermal bridges can seriously reduce the performance of the window

- A well placed poor performing window can be better than a badly placed Passivhaus window

- Choose BBA Certified and/or BSI Kitemarked windows

- Choose with BSI Kitemark Double Glazed Sealed Units

- Choose Windows with Secure by Design Accreditation

- Choose Windows with TWAS accreditation or equivalent

- Choose Windows with Passivhaus accreditation or equivalent

- Get them fully finished in the factory on all faces, but avoid oil paints, choose microporous high build paints or stains

- Always use an approved accredited or manufacturer trained installer

Effectiveness:

- In wood windows consider aluminium sill and bottom beads for durability in the most vulnerable locations.

Yardstick:

Maintenance issue:

- Anodized or coated aluminium give a long life but the guarantee relies upon a regular cleaning regime

- Painted and stain timber have a relatively short life between recoating

- Stains that can accept overcoating with more of the same and at worst needs sanding down; are easier to maintain than paint that may need to be removed or at least sanded down to accept over-coating

- Premature ironmongery failure in PVC windows is one of the reasons for shorter life in use than design life

- Peabody estate proactively wash windows inside and out, to inspect and do preventative maintenance to PVC window’s ironmongery to avoid premature failure and check on the health and wellbeing of the occupant at the same time.

Industry Initiatives:

RecoVinyl:

- An EU fund for recycling extruded rigid PVC from window and other waste exists and a number of waste handlers are engaged in the scheme in the UK.

- Only one window manufacturer was involved in RecoVinyl so most are not using recycled content in their frames

- Most of the PVC that is recycled goes to make something other than windows, this does not make the windows any better

- (despite BRE Green Guide to Specification and LCA theory)

- Use of virgin PVC sheath over recycled PVC is adopted

- Use of recycled PVC in the core of a window section may not be a clever solution because the best PVC windows are steel reinforced in the core of the section

- The steel core PVC gives ironmongery screws something substantial to bite into

- Premature ironmongery failure in PVC windows is one of the reasons for shorter life in use than design life

Information sources:

- Window Materials

- Wood paints

- Wood preservation

- Glass:

- Ventilation:

BIBLIOGRAPHY:

- BedZED BioRegional Guide

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

16th December 2012 – 17th August 2021

Images:

GBE CPD

GBS Green Building Specification

P14 Air/wind tightness systems

- P14 RSWS Airtghtnss A15 BRM 060414 doc

- P14_RSG_Airtightnss_A03_BRM_091212.doc

British Library Euston Science Reference Information Service Clerestorey Window Solar Shading

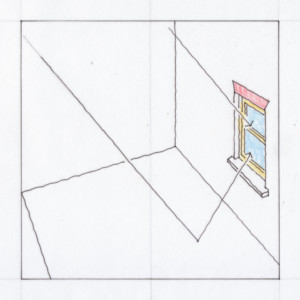

GBE Lecture WallOpeningWindowDoor A02 BRM 221018 9H1 PDF Handout Cover

GBE Lecture WallOpeningWindowDoor A02 BRM 221018 S1 Show Cover PDF

Portcullis House London, Solar shading over windows, oriels, dormers, on South and West facades IMG_2462

UEA Enterprise Centre Entrance Courtyard North Wing South Elevation, Solar shading, panel cladding, Ventilation Louvres, Windows, Flint Filtre Drain Trench landscape

Expanding foam

Ventrolla Refurbished & Upgraded Vertical Sliding Sash Window

If you wish to reproduce images, feel free, but please acknowledge the source.

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

29th July 2014 – 17th August 2021

L10 Windows Rooflights Screens Louvres Checklist

See Also:

GBE Compare

GBE Jargon Buster

GBE Jargon Buster Theme

- Air/Wind Tightness (Jargon Buster Theme) N#1391

- Timber (Jargon Buster Theme) N#1462

GBE Jargon Buster

Initials Abbreviations & Acronyms

- BBA

- BSI

- BRE

- BWF

- DGSU

- FSC

- GGtS

- PVC

- PVCu

- TGSU

- TWAS

- UPVC

- BSI Kitemark

- BRE Green Guide to Specification (GGtS)

- British Board of Agrément (BBA)

- Composite Window

- Double Glazed Sealed Unit (DGSU)

- High build stain

- Micro porous paint or stain

- Passivhaus

- Polyvinyl Chloride (PVC)

GBE CPD

- GBE CPD L10 Windows Show PDF

- GBE L10 Windows (CPD) G#421 N#42

GBE Lectures

- Building Envelope Principles (Lecture) G#31815

- External Walls Openings Windows Doors (Lecture) G#19226

GBE Checklist

New Build

- L10 Windows

- L15 Solar Shading

- L19 Ventilation Louvres

- L40 Glass and Glazing

- M60 Paint/Clear finishes

- P12 Ironmongery

- P14 Air/Wind Tightness Systems

- Z10 Purpose Made Joinery

- Z20 Fixings/Adhesives

- Z22 Sealants

- C50 Repairing/Renovating/Conserving metal

- C51 Repairing/Renovating/Conserving timber

GBE Issue Papers

- Overheating (Issue Paper) G#145

GBE Links

- FSC UK

- BSI

- BWF TWAS

- Secured by Design

GBE Calculator

- U Values to Energy consumption to CO2

- Embodied Energy & Embodied Carbon

GBC Calculator

GBE Datasets

- GBE Timber Species Schedule N#1351

- Bath Uni ICE Database

GBE Jargon Buster

- ICE Database (Jargon Buster) G#1018 N#1037

GBE CAD

- 2D and 3D SketchUp Product files

- SketchUp files of Construction Sections

GBS Green Building Specification

GBE Accessories

- Corner glazing steel post insulation:

- steel box window section Aerogel PDF

- Pultruded Windows:

- Pultec Fibre Reinforced Composite Window (Product) G#1591 N#1522 No longer available

GBE Projects

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

16th December 2012 – 17th August 2021