Thermal Insulation masterclass CPD

GBE > Encyclopaedia > Files > CPD > Topics > G#40839

About:

GBE CPD Invitation

- The seminar text is posted lower down this page

Thermal Insulation master class

Green Building Encyclopaedia

Continuing Professional Development

- BrianSpecMan Murphy of Green Building Specification, Green Building Encyclopaedia and Green Building Calculator has been invited by Marguerite Murdoch to Boathouse Design Studios to offer one or many CPD seminars to resident local practices.

- Brian is not a manufacturer so has no product to sell,

- he will provide independent opinion; introduce and explain:

- many alternative materials,

- the multitude of properties of conduction, convection, radiation and reflection thermal insulation,

- and their healthy, environmental, resourceful, appropriate, competent and effective applications.

- Discussion will cover:

- materials,

- embodied and in use energy and carbon,

- hygroscopicity for moisture management and

- decrement delay to resist summer overheating

- There will be many samples to handle,

- glimpses of Green Building Calculator’s Insulation tables,

- clues about robust specifications

- to defend against substitution

- and a whole lot more.

- Future CPD could address Overheating beyond Part O, Green Building Calculator, Green Retrofit Calculator, selected from 1000 hours of CPD

© 2023 BRM ASWS NGS GBE GBC GRC GBL Brian Murphy

GBE CPD Metadata

- File Name:

- Show:

- GBE CPD JP10 Thermal Insulation A04 BRM 060723 S205

- Handout:

- GBE CPD JP10ThermalInsulation A04BRM060723 9H25

- File Type: PDF of PPTX

- File Size:

- PDF Handout: 10 mb

- PDF Show: 69 mb

- Number of Slides/Pages:

- PDF Handout: 23 Pages

- PDF Show: 205 Slides of 218

- Created for: Architects In-house CPD with samples

- Presented to: Boathouse Design Studios & local Architects & Engineers

- Author: BrianSpecMan aka Brian Murphy ONC HNC Construction BSc Dip Architecture (Hons+Dist)

- © GBE GBL GBC NGS ASWS 2023

- Created: 03/07/2023

- Revision: A04

- Updated: 06/07/2023

- CI/SfB:

- CAWS 1987: P10, P11

- Uniclass I: JP10, JP11

- Tags: CPD, Lecture, In-house CPD, Samples, Insulation, P10, P11

- ProductSets: Methods of Construction, Insulation Materials, Building Elements, Elemental performance, product Performance, Hygroscopic, Hydrophobic, Decrement Delay, Thermal mass, Specific Heat capacity.

- UserGroups: Students, Architects, Assistants, Technicians, Constructors, Contractors,

GBE CPD Content

(without images; See the slide show for the pictures)

JP10 Thermal Insulation Master class

- BrianSpecMan 4th July 2023

- This Presentation on GBE:

- Find this file on GBE websites at:

- Go there for:

- the latest update

- versions presented to different audiences

- the whole presentation, all of the hidden slides

- other file formats:

- Handout, Show, PDF, (PPTX in shop)

- Links to related: GBE & GBC CPD & other content

- CPD, Lectures, Checklists, Jargon Busters, Issue papers, Q&A, Links, etc.

GBE CPD Seminar Series

- Educational Objective:

- Comprehensive introduction to subject: Insulation

- emphasis on environmentally sustainable solutions

- design primer: addressing principles and solutions

- technically rich: materials, construction, services & testing

- Related GBE CPD Seminars indicated

- Questions and answers for each subtopic in file

- Audience:

- Architecture Students Part 1 Year 2

- CPD update for all levels of experience & knowledge

- Delivery:

- 45 minutes depending upon audience participation

- Reading 10 minutes

Thermal Insulation Functions

- In use Carbon and Energy Reduction

- Thermal comfort Moisture management

- General Competency Issues

- Comply with Code of Practice or Workmanship British Standards or WOBS

- Products manufactured to BS standards and BSI Kitemarked ideally (or ENs and Kitemark)

- BBA Certified systems if no Kitemark

- Manufacturer recommendations should never be ignored

- BBA certificates should be checked for limitations too, stay within them

- Check currency of test evidence

- (ideally post Grenfell)

Regulated Issues

- Stuff we should understand

- k values of materials and products

- r values of materials of known thickness

- Surface resistivity at faces and in voids

- U values of whole elements

- R values if European/International

- Do you do your own calculations?

- If not, do you check them for competency?

- I have found manufacturers fudging values

- GBC V2 Includes U value calculators for all elements

- GRC V1 will too when issued

Unregulated Issues

- Stuff green manufacturers understand

- but we tend not to know nor exploit

- More research is done but not readily accessible

- Hydrophobic insulation

- Vapour closed construction

- Hygroscopic insulation

- Vapour open construction

- Breathing walls & roofs

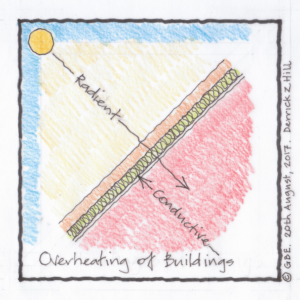

Unregulated Issues (BRAD O)

- BRAD O does not understand opaque building envelop permits solar radient heat inwards

- Solar Radiation Heat gain

- K value

- Density

- Specific Heat Capacity

- Thermal Mass

- storing heat in its thermal mass, if it has any

- Decrement delay or Thermal lag

- heat passage over time through insulation to interior

- Thermal Mass

Meeting Targets: means Avoiding Substitutions

- Specify the reasons you chose it

- Make those reasons the criteria for substitution equivalency

- Don’t say ‘or similar’ say ‘or equivalent’ and check equivalency

- In annotation (don’t undermine the specification)

- Nor in the specification it encourages substitution

- Police your specification

- Choosing Contractors, Suppliers, Installers

- At price gathering and at tender stage

- On site: Delivery tickets, packaging, products

- As installed

- At stage payments “Here be dragons”

- (signing off stage payments approves surreptitious substitution)

Violet v Green Contractors

- Violet contractors know what they know

- Have supply chains in order

- Buy the day they need it from merchants

- They don’t like change: Business as usual

- Get them to do the TGR’s Futureproof online training courses for sustainable retrofit subcontractors

- https://www.futureproof.uk.net/

- futureproof@org.uk

- So they know why and how to change and want to change

- And not bother to bring spurious substitutions

- And get satisfaction they are part of the solution

Cost savings now, cost later

- Working with your client and the contractor

- Understand that initial cost savings will probably increase :

- in-use cost

- in use Energy and Carbon

- Embodied Energy and Carbon

- Use Green Building Calculator to see all of the costs and impacts before you decide

- Making changes in GBC will instantaneously provide you with the consequences of any change of specification or targets

Pay back & carbon back periods

- Renewable energy systems are an add on cost

- Push-back comes in the form of ‘what is the pay-back period’ usually associated with energy costs

- More importantly are carbon-back periods

- If your client is switched on to carbon saving

- Provide them with that information too

- Green Building Calculator aims to provide this data in future

- Focus on Insulation payback periods

- Focus on high specification window payback periods

- Focus on the cost of adding and running air conditioning

- Focus on PV to EV on the drive not having to pay for fuel again

- Challenge payback period of £1000 tap or door handle

Adding real value

- Estate agent’s perceived ‘adding value’: if your selling it

- Location Location Location in relation to schools

- Increasing floor area,

- Posh kitchens and posh bathrooms

- Kerb appeal

- Neutral colour, clutter-free interiors

- Home owners perceived adding value:

- Being able to boast about how cheaply you extended/altered your house is not adding value

- With increasing fuel and living costs, long term low running costs need to be perceived as adding value?

- A to G ratings enable engagement

- Boasting your 6 Bed house costs £50/year to heat and cool not £2000/year at the school gate has to be seen as adding value?

History Lesson

- Just my opinion

- GBC will confirm or not

Pre 1919 – 1962 Building Regs.

1995 Building Regs. AD L

2016 Building Regs. AD L

2023 Passivhaus & Biobased

CO2 and Energy demand targets

- Set out to meet or exceed:

- Kyoto, Paris, EU or UK CO2 targets,

- or ACAN, LETI, RIBA campaigns (but silos still apply)

- Do not limit projects to complying with Building Regulations Approved Documents L1A, L1B, L2A, L2B they are not yet aiming to meet any targets

- Weak Regulations since 1965 could be blamed for Climate Change

- but coal, oil and gas are the real culprits

- EcoHomes & Code for Sustainable Homes

- Challenged Building Regulations

- CfSH strived for Zero Carbon buildings by 2016,

- Industry responded and invested for one up man ship

- Lots of bad application and lessons learned

- but were optional,

- challenged by profit hungry developers and now no longer available

- Some T&CP still ask for them

Zero Carbon?

- Claim:

- Code for Sustainable Homes Level 6

- Latest info: Level 5

- Stewart Milne

- Arup

- Look at the heat loss/gain towers

Reduce Your Targets

- Reduce heating, cooling, ventilation and air-conditioning demands towards zero

- Insulation costs less than heating and cooling plant so insulate

- Windows: U value of 1.0 W/m2.K or better targets 0.75 W/m2.K

- Walls: U value of 0.1 W/m2.K or better

- Airtightness: Building Regulations Approved Document L

- less than 1, (0.6 PH) not 10 required by BRADL

- An existing unusable library survey

- Howling wind through windows

- Papers fluttering across table

- Airtightness tested at 8

- Then reduced to 2 in an hour with smoke wands and tapes

Form Factor

Form factors

Form Factor dictates heat loss

- Ratio between external envelop and floor areas

- Spherical is optimum but impractical and costly

- Compact square plans, cubical volumes best

- L, C, O, I, H, T, X shaped plans worse

- Bungalows worse than Apartments

- Villas worse than Terraces

- Bay, Oriel, Dormer, Porch, Extensions, Conservatory, recessed covered walkways: all worse Form Factor

- Towers with multiple occupancy: okay

- Towers with single occupancy: not so good

- Form Factor included in GBC V2

Form Factor suggests Targets

- With a Form Factor Calculator

- You can determine U value Targets

- That are more important than BRADL

- A large form factor will always use more energy to heat or cool

- So U value should be correspondingly more onerous

- or it will be expensive to occupy

Changes of Direction/Plain

- Junctions between elements

- Corners between walls

- Angles between planes

- Are all costly:

- Are all more labour intensive

- All generate offcut waste

- (in factory, on site or both)

- Are often thermal bridges that loose heat

- Are often air leaky where heat is also lost

Orientation

- Orientation of what?

- Building orientation: can influence building performance

- Plan shape and orientation

- Area of external opaque surfaces facing sun,

- Pitched roofs in particular (potential overheating),

- Volumetric shape (form factor)

- Plan shape and orientation

- Windows, Glazing: solar heat gain

- South: needs shading in summer, solar access in winter

- East & West: Morning and evening heat gains at low angles

- North: heat free daylight, but heat loss too

- Roofs: facing the sun at different times of day

- For Renewable energy systems

- Use PV on more roof orientations to match energy supply to energy demand over longer period of day,

- Do not maximise battery capacity for mid day only gains

- Not just south facing and not just at 30 degree pitch

- Vertical in winter (Bill Dunster at FutureBuild 2023)

- Potential to overheat attic and top floors

Really want this?

- Form Factor: So high

- South facing?: No shading

- 6 bathrooms: Who’s cleaning them?

- £100,000: to pay for:

- Winter heating bills

- Summer air conditioning

- House maid

Orientation

- Solar heat gains can be beneficial in winter if exploited well

- Solar heat gains can be detrimental in summer due to overheating

- Opaque building fabric needs thermal mass OR

- Insulation material choice will exacerbate or solve overheating

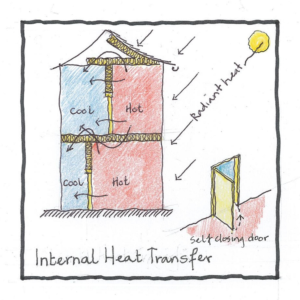

Internal Heat Transfer

- Keep heat in its place of arrival

- Maintain safe refuge on the cooler side

- Insulate internal floors and partitions

- Self closing doors

- Promoted by BedZED

- Rotate around rooms of the house to stay cool

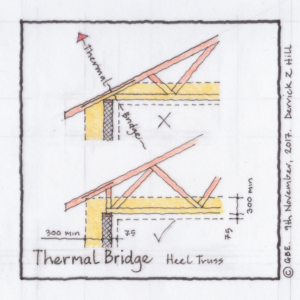

Thermal Bridges Geometry dictates & Material choices

Thermal bridges will ruin any choice of insulation material performance

- Thermal bridges will let conducted heat out, conducted coolth in and solar radiant heat in

- Eaves details are most vulnerable

- 300 mm of insulation reduced to 50 mm is asking for trouble

- Risking interstitial condensation, surface condensation, mould, structural failure, asthma, toxic mould and death

Thermal Breaks

High Density Expanded Polystyrene

- Strong enough for nails and screws

- For securing windows, doors, etc.

- Embedded in walls

- Moisture tolerant

- Thermal insulation but poorer k value

Thermal Bypass & Wind Washing

- Wind washing at eaves

- Essential eaves ventilation to prevent condensation

- Cold air from eaves ventilation can blow the warmth out of the ceiling insulation

- Install a wind baffle to maintain ventilation route past the insulation edge

Thickness

- Carbon and Energy Reduction

Insulation, Insulation, Insulation

- Spend money on insulation, its cheap

- Save money on heating and cooling plant, it’s expensive, reduce plant room sizes

- Save money on heating and cooling bills

- it will get more expensive over time

- Peak oil has been passed

- Prices have been rising

- Government will not intervene

Principle still true could do with up to date project numbers

GBC Green Building Calculator

- Materials > Formats > k values > U values > Thicknesses >150 options in GBC V1

Showroom Tour 1:1 Section models

- Thermal & Acoustic Insulation

Different eras and climate zones

Another CPD seminar

Wildlife Action

Inhabitation

- Rats, mice, birds, bats enter buildings for warmth, dryness, gnawing food, breeding and sleeping

- Rodents teeth grow continuously, they gnaw materials to keep them short, anything will be tried including timber structure, cables, insulation and membranes

- Insulation is good bedding material

Wildlife Action

- Extruded and expanded polystyrene and even high-density mineral fibre are very seriously attacked by “wildlife”.

- That’s another mechanism by which you can lose most of the r-value of your insulation.

- None of them appear suitable for use in ground contact as was being recommended just a decade or two ago in Sweden, USA and elsewhere.

Hygroscopic v Hydrophobic

- Moisture and its effect on performance

Hydrophobic Insulation in masonry

- Glass and rock mineral wool thermal and acoustic insulation

- If used in wet construction e.g. masonry cavity wall the moisture content of the wall is expected to be 3% MC

- Rainwater can pour down the inside face of the external leaf

- Hydrophobic materials in these conditions will absorb moisture in the surface

- The water will occupy the air spaces and prevent the insulation from acting as insulation

- Its performance drops off unless it can lose the water

- High resin content can offer some resistance to water uptake

- Fibre orientation or disorientation can discourage capillary attraction into the depth of the insulation

- Allegedly the insulation keeps the moisture close to the exposed surface and little of the insulation’s thickness loses performance

Hydrophobic Insulation in timber frame

- Glass and rock mineral wool thermal and acoustic insulation

- If used in dry construction e.g. timber frame wall the moisture content of the wall is expected to be low

- However compromised vapour barriers (VB) are only a Vapour check (VC) and some moisture will enter the construction

- Hydrophobic materials in these conditions will adsorb moist air and water

- The moisture will occupy the air spaces and prevent the insulation from acting as insulation

- Its performance drops off unless it can loose the moisture

- High resin content and non absorbent materials offer resistance to moisture uptake into the fibre so it remains in the airspaces.

- 1:5 ratio is critical to the moisture passing through driven by warm air

- If the insulation holds the water it can hold the water against timber sections

- Timber sections kept wet will rot

Hygroscopic Insulation

- Any natural plant based material: hemp, straw, flax, coconut husk, cellulose, sheep’s wool, grass, etc.

- Air trapped in material is what makes insulation work

- Water does not work in the same way

- Moisture laden air or interstitial condensation occupies the space that air would

- Stops hydrophobic insulation from insulating

- Hygroscopic insulation absorbs the moisture into the fibre leaving the air spaces to insulate

- Releases the moisture when conditions are right and it leaves the construction and building

Hygroscopic Thermal Insulation

Decrement Delay Thermal Lag

- P10 Insulation

Roof top extensions

- Planners insist on top floor additions set-back

- Structure needs lightweight construction

- Comes with wrong insulation

- Will overheat

- Needs air-con

Radiant heat through 50 mm. of thermal insulation materials over time Warms the space beyond

- Radiant verses Conductive heat flows

- Insulation needs to resist both or overheating occurs

Radiant v Conductive

- Thermal Insulation:

- Once radiant heat gets in it warms the space and the warmth cannot get out through conductivity insulation

Radiant v Conductive

- UK Government funded insulation programmes

- Refurbishment and retrofit

- Cavity insulation

- Attic insulation

- Cheap materials: glass and stone wool or polystyrene: all conductive insulation

- Will overheat top floors

Radient heat test

- The insulation heats up with solar radiant heat

- The insulation delays the passage of solar radiant heat through thickness of insulation

- British Library Euston saw asphalt roofing laid on Foamglas on concrete, heat bounced back and kept asphalt warm, not setting and running down slope, pushed back by installer until cool enough to set

- Uninsulated concrete would soak up the heat and the asphalt set quickly

Building Integrated Renewables

- Building Integrated Renewables

- Is it really a good idea?

- I don’t think so

- Non-BIR ventilate below and PVs perform better

- BIR PV radiate below into a hot attic

Decrement Delay Equation

- GBE Green Building Calculator

- Will be added GBC V3?

Acoustic Insulation

- P10 Insulation

Sheep’s Wool Acoustic Isolation

- Used within floor finish build up

- Isolate hard top surfaces from sub-construction

- Footfall should not transfer noises to sub-floor

Airtightness Accessories

Building Regulations AD L update

- Inaccurate fit rigid insulation (expanded plastic/foil face)

- Heat loss in winter

- Heat gain in summer

- Coolth loss in summer

- Cold gain in winter

- Higher than necessary energy demand

- And carbon from that fuel

- Interstitial condensation risk

- Mould risk

- Rot and Structural failure risk

- The only practical competent solution: GapOTape

- Self adhesive compressible insulation

- Bonded to edge of rigid insulation boards

- Squeeze into framing zone

- Airtight but forces all moisture through timber framing

Building Regulations AD L Airtightness

- Inaccurate fit/seal electrical boxes and membranes

- Heat loss in winter

- Heat gain in summer

- Coolth loss in summer

- Cold gain in winter

- Higher than necessary energy demand

- And carbon from that fuel

- Interstitial condensation risk

- Mould risk

- Rot and Structural failure risk

- A practical competent solution: Bead Master

- Ready made square, rectangular or circular beading

- Makes airtight seal with plaster applied

- Sharp knife & pop out centre panel

Window perimeter insulation

- Self-adhesive Compressed foam strip

- Fix to perimeter of windows

- Install windows within 3 hours

- Foam strip will expand to fill the gap

- The closer the opening to the windows size

- The more compressed the strip remains

- Weather and wind tightness, acoustics and thermal performance possible

Thermal Insulation Materials

Mineral Insulations

Fired clay

- Extruded Block:

- cellular and long pathways

Extruded Fired Clay Block

- Like bricks only much more

- Clay with sawdust that burns off

- Many small air bubbles throughout clay

- Extruded with many air pockets

- Small section to minimise eddy currents

- Solid parts create a long pathway from one side of block to the other

- Better k value than filed clay brick

- Better actual performance

Aerogel with Mineral Fibre

- Aerogel

- Silica in solution, water removed

- Leaving silica matrix and

- Microscopic air bubbles

- Added fibres to reinforce quilt

- k values better than the best plastic insulation

- Micro porous

- Good fire performance (some tested)

Aerogel in Paint

- Aerogel in Paint

- Government Magic wand!

- Insulating paint

- 1 mm of Aerogel not a good U value

- It’s a small improvement in thermal comfort

- But mostly to the touch only

Glass Mineral Fibre

- Glass Wool

- Middle of the road k value

- No decrement delay at normal density so exacerbates summer overheating

- Combustible?

- Hydrophobic: No moisture management

- Only use in vapour closed thermal construction

- Used for acoustics a lot

Stone Mineral Fibre

- Stone Mineral Fibre

- Its Cheap and large market share

- Created from abundant natural resource (stone)

- Also uses Pumice (volcanic rock, renewable but not abundant)

- Saves in-use winter energy (so do all insulation materials)

- No Decrement delay at thermal insulation densities so exacerbates summer overheating

- Offers no solar radiation heat gain protection in summer

- Uses more embodied energy to make it

- Recyclable (after many years of use but also degrades with brittleness so not reusable)

- Hydrophobic (repels water so water is held in air spaces so cannot insulate, can hold water against timbers)

- Nicknamed by greenies: Rotwool

- Fire resistant densities:

- Non-combustible

- Used in fire resistant assemblies

- Almost unique in rainscreen cladding thermal insulation (post-Grenfell)

Cellular Glass (CG)

- Foamed into slabs and boards or nuggets for aggregates

- Cellular Glass boards

The use of Foamglas on British Library Euston (BLE) was extensive

- Non-combustible in a Section 20 building

- High rise, large m2, public assembly

- Applications: next slide

It was used in: (BLE)

- Basement perimeter wall internal gutters with asphalt

- Foamglas slabs T2 or T4 (thermal) (no paper surface)

- External Cavity walls partial fill

- Foamglas wallboard T2 or T4 (thermal) (papered surface)

- Forecourt waterproofing with asphalt or high performance felt

- Foamglas S3 (structural) and Foamglas slabs T4 (thermal)

- Flat roofs asphalt

- Foamglas slabs T4 thermal (no paper surface) in hot bitumen flood coat

- Floor insulation under screeds

- Foamglas slab S3 (no paper surface)

- Exposed floor soffit insulation

- Foamglas T4 Aluboard (aluminium foil faced)

- and many other details

- But not outside of the basement wall or basement suspended lowest floor.

Application

- In all cases the intention was for:

- Bonded to inner leaf and fully filled joints in (paper or foil surfaced) boards to walls and soffits: 2 part adhesive

- (not papered surfaced) slabs in bitumen flood coat to asphalt roofs, gutters and waterproofing to ensure joints filled and tops are squeegeed with excess bitumen, followed by protective/waterproof membranes.

- In all cases the insulation was protected from moisture ingress and frost damage, even though the insulation itself is water and vapour proof.

Frost damage

- Surface frost damage was a subject that was introduced to us on BLE late in the project but it was not an issue so the specification did not need to be changed in any application.

Precautionary principle (BLE)

- Despite Foamglas being a waterproof and vapour proof material

- BLE did not rely on this and always protected it from water

- treated it as a 2nd or 3rd line of defence in construction on a building with up to 500 year design life for basements and 250 years for superstructure 120 years for external envelop. (BLE)

Water/Damp proof membranes

- I have recently prepared PowerPoint on foundations and ground floor construction for Architectural students

- in each I have suggested that the insulation is best kept dry to ensure its optimum performance, showing a DPM below the insulation

- so it is my intuitive choice of construction sequence

- But not everybody does it that way.

- Exception: Ground gasses need a way out and then the G/DPM need to be above an insulating ventilation labyrinth to perimeter or vents

Foamed cellular Glass & GWP

- Cellular Glass is a GWP of 0.2

- per m2 for 150mm of material

- this is based on our EPD we now have in place for France and Germany.

- Recommended installation details always show a protective layer of waterproofing to prevent the ingress of water to the surface cells which can ultimately lead to Freeze/ Thaw damage in certain conditions.

Foamglas Belgium Factory Visit

- As I indicated when we met, I would like to invite you and any sceptical colleagues to come and visit our manufacturing plant in Belgium early next year, where we can demonstrate our process and capabilities physically, rather than conceptually.

- We as a business have nothing to hide and would warm to any challenging questions.

- We have been producing our material for over 50 years and with over 66% re-cycled glass now in our product, we feel our environmental credentials and product performance track record to be of the highest in the industry.

Waterlogged Foamglas?

- Since Foamglas is closed cell the amount of water in the materials can only be at the surface cells.

- I find it hard to understand how the material can be ‘heavy from absorbed water’

- Or everything PC say about Foamglas: closed cell, water resistance, vapour resistance is to be ignored.

- Can frost damage extend deep into the board?

- I would have thought the insulating characteristics would prevent it.

- Could it have suffered thermal shock and/or frost damage and cells fractured deep into the section thus allowing water in further?

- If the material had been crushed before installation or after by backfilling then the cells could have been opened ready to receive water.

- And this would have to come from above heading down rather than ground water coming up.

- I do not understand this at all.

Expanded mineral insulation

Expanded perlite insulation

- Expanded Perlite

- Expanded or Exfoliated?

- Mineral

- Thermal and Fire performance

Calcium Silicate Expanded mineral insulation

- Calcium Silicate

- Invented for historic building fabric external masonry walls

- Aerated mineral matrix board

- IWI Internal wall insulation

- Bonded direct to internal surface

- Moisture permeable

- Controls prevents condensation mould

Autoclaved Aerated concrete

Autoclaved Aerated Concrete AAC Aerated Concrete AC

- Steam cured concrete: energy intensive

- Binder: OPC Cement matric

- High Energy High Carbon

- Aggregate: Sand or fine aggregate

- Aluminium oxide: Saponification bubbles

- Format: AAC block or wall slabs

- Format: AC insitu concrete

- AAC: Internal wall or partition, wall panel

- AC: self insulating ground floor slab

Animal

Sheep’s Wool

- And goat hair

- Hygroscopic Insulation:

Sheep’s Wool

- Sheep’s wool

- When on the sheep’s back they are kept warm in winter and cool in summer

- Hygroscopicity absorbs moisture into fibre and the insulating action is maintained

- But also in summer moisture loss has cooling effect and in winter moisture gain has warming effect

Sheep’s wool: Cool in Summer

- When outside temperature increases and begins to heat sheep’s wool, it releases moisture;

- has a cooling effect on the fibre which reduces the flow of heat to the inside of the building

- Can reduce peak temperature by up to 7°C compared to alternative insulation

Sheep’s wool: Warm in Winter

- In the winter the absorption of moisture by sheep’s wool insulation

- can increase peak temperature by up to 4°C

- when compared to buildings in which alternative forms of insulation are installed.

Bird feather

- Eider down

- Bird feathers

- Used in bedding quilts

- Crate still air pockets

- Quilts need dry-cleaning but cost more to clean than buy new

- Big waste stream to divert from landfill

- Interreg Project investigated converting into construction thermal insulation

Plant fibre

Hygroscopic Thermal Insulation

Coconut Husk Fibre

Plant fibre – Essence

- Dried fibres minus essence

- Loose, Batts, Quilts, Boards

- MOR k value similar to Mineral Wool

- +Specific Heat Capacity: High

- +Density provides Decrement Delay

- Good winter and summer performance

Plant Fibre

- Cork Bark

- Hemp shiv

- Flax stalks

- Straw stalks

- Straw board

- (Strammit: Not compatible with UK Climate)

- Grass cuttings

- Cotton (but water & chemical intensive)

- Denim (ditto)

- Many more

Cork

- Loose chips, Boards, Tiles,

- Added to plaster

Cork: Tree Bark

- Portugal, Seasonal production, harvested for limited number of years

- Tree based: Bark and binder

- Carbon Sequestration

- Binder: can be combustible, flammable initially

- But the cork will char like timber and become fire resistant

- Many formats:

- Loose: Chips

- Rigid: board, sheet,

- Flexible: floor tile

- Decrement: Radient Thermal Insulation

- Hygroscopicity: Moisture Management

- Chipped: Added ingredient in renders

Cork: Floor tile

- Portugal, Seasonal production, harvested for limited number of years

- Tree based: Bark and binder

- Carbon Sequestration

- Flexible: floor tile: Thermal comfort on feet

- 2-3 mm thickness: good k value, poor U value

- Decrement: Radient Thermal Insulation

- If laid on concrete it can be warmed through cork tile

- May get a surface sealer preventing Hygroscopicity

- Hygroscopicity: Moisture Management?

Strawboard

- 50 mm thick panels

- Compacted straw

- Paper surface all round

- Good k value for winter

- Good Decrement factor for summer

- Good fire performance (doors, partitions)

- Good Acoustics (Partitions roofs walls)

- Not good in UK climate: any grains can grow and board expands

- Disappeared from UK market 1970’s

- R&D at Brunell University trying to solve it

- Very effective in other dryer climates

Wood fibres

Wood Fibre Batts or Slabs

- Recycled wood fibre milling waste

- Suitable insulation in, above or below:

- Framed Walls, Roofs, Floors

- Solid Masonry: IWI with clay and EWI with lime render

- High acoustic density

- High decrement delay

- (Specific Heat Capacity, Density and k value)

- k value worse than rock,

- Increased thickness needed

- Phenomenal summer performance compared to:

- glass/rock mineral fibre

- expanded polystyrene plastics insulation

Dense wood fibre rigid board

- Wet or dry manufacturing process

- Lectin released and used to bind fibres

- k value little worse than stone wool

- Greater thickness needed for winter

- High decrement delay: good for summer

- Hygroscopic:

- good for moisture management,

- use in vapour open construction

- Rigid: can span between framing

- Versatile applications:

- Roofs Walls Floors

- Inside or outside framing

Wood Fibre Systems

Dense wood fibre (DWF) systems

- Original inventers or DWF

- Continuously inventing whole systems

- Versatile applications:

- Roofs Walls Floors

- Inside or outside framing

- IWI & EWI

- Purpose made ‘Systems’ including accessories and finishes

Dense wood fibre systems

- Stone walls lumpy profiles

- Rigid boards would create cavities

- Where moisture cannot jump cavities

- Moisture stops at cavity

- Will reactivate any spores in the cavities

- Mould can grow undetectable

- Vapour permeable adhesive bonded to stone wall, no more cavities

- Moisture transport across wall restored

- Vapour open system

Wood Fibre Rigid & Soft Insulation

- Stone walls lumpy profiles

- Rigid boards would create cavities

- Where moisture cannot jump cavities

- Moisture stops at cavity

- Will reactivate any spores in the cavities

- Mould can grow undetectable

- Compressible insulation on back face mould to lumpy profiles of stone wall, no more cavities

- Moisture transport across wall restored

- Vapour open system

Cellulose Fibre

- Recycled Newspaper Recycled Magazines

Cellulose Fibre Flake

- Recycled newspaper/magazine

- Cellulose fibre flake insulation in:

- Framed Walls, Roofs, Floors

- High acoustic density & high thermal mass whilst k value similar to rock

- Phenomenal summer performance compared to:

- glass/rock mineral fibre

- expanded polystyrene plastics insulation

Recycled Cloth Insulation

- Recycled denim

Recycled Denim

- Matisse from France

- Available in UK

- Denim clothes shredded

- Batts

- Hygroscopic: Moisture management use on vapour open construction

- Some thermal mass

- Used in framing zone of lightweight timber frame (LTF)

Recycled Tweed

- Made in Scotland

- Tweed clothes shredded

- Batts

- Hygroscopic: Moisture management use on vapour open construction

- Some thermal mass

- Used in framing zone of lightweight timber frame (LTF)

Plastic Insulation

- Plastics

- Potentially less materials

- Potentially better winter performance

- Potentially worse summer performance

- Specification, detailing and Installation workmanship undermines performance

- Gappy insulation is very ineffective

- BRADL has been updated to force use of GapOTape or equivalent

Polypropylene

- ‘Non-itch’ marketed as an improvement over glass or stone mineral wool

- Finite resource: Petrochemical, hydrocarbon, oil bi-product

- Fossil Carbon: Adds to Climate Change

- Plastics manufacturing generates:

- 5% of man made CO2

- And lots of heat energy and its CO2

- Hydrophobic, Moisture impermeable:

- use in vapour closed construction

- Incompatible with historic building fabric

- No Decrement Delay: can exacerbate overheating

- Applications:

- Can’t think of any useful competent appropriate applications

- Promoted as a replacement for glass and stone wool I remain unconvinced

Multi Foils

Radiation & Reflection

- Multi-foil insulation rolls exploit these characteristics

- Many layer of metalised plastic foils and expanded polyethylene sheets bound together by stitching

- Use of surface resistivity relies on cavities of air space

- Outwards

- Reflects heat back in

- Insulates between reflective foils

- Does not conduct heat outwards

- Does not radiate heat outwards

- Inwards

- Reflects solar heat back out

- Insulates between reflective foils

- Does not conduct heat or coolth inwards

- Does not radiate heat or coolth inwards

Controversy

- Manufacturer claims 19 mm. is equivalent to 250mm. of rock mineral fibre

- BSI’s Hot box test method does not support this claim

- Whole house tests do allegedly

- AECB challenge: manufacturer trying to prove it

- Dropped the existing product and created a new one with one more layer loosing all the baggage

- Check their figures

Foamed Plastics

- EPS Expanded Polystyrene

XPS Extruded Polystyrene

PIR Polyisocyanurate

PUR Polyurethane

Phenolic

Expanded Polystyrene (EPS)

- Finite resource: Petrochemical, hydrocarbon, oil bi-product

- Fossil Carbon: Adds to Climate Change

- Plastics manufacturing generates:

- 5% of man made CO2

- And lots of heat energy and its CO2

- Hydrophobic, Moisture impermeable:

- use in vapour closed construction

- Incompatible with historic building fabric

- No Decrement Delay: can exacerbate overheating

- Applications:

- Below Ground floor thermal conductivity insulation

- Protected by Damp Proof Membrane (DPM)

- Inverted Flat roof construction? multi-layered to minimise cold bridging

- Needs decrement delay somewhere in the roof element

- Below Ground floor thermal conductivity insulation

Extruded Polystyrene XPS failures

- Below Ground Insulation

- Wet and failed extruded polystyrene,

- 3 reported instances of this, 2 in Belgium and 1 in France and all on Earthships.

- Every building material suffers from failure if badly installed or installed outside manufacturers standard details.

- In all the cases, failure was due to poor waterproofing and freeze thaw degradation of the material.

- In the cases investigated, the contractors had failed to install either a waterproofing layer or where the board product was used, had cut corners by not using any sealant on the joints.

Recycled Expanded Polystyrene (REPS)

- Finite resource: Petrochemical, hydrocarbon, oil bi-product

- Fossil Carbon: Adds to Climate Change

- Plastics manufacturing generates:

- 5% of man made CO2

- And lots of heat energy and its CO2

- Recycled content, Or Graphite added

- Hydrophobic, Moisture impermeable:

- use in vapour closed construction

- Incompatible with historic building fabric

- No Decrement Delay: can exacerbate overheating

- Applications:

- Below Ground floor thermal conductivity insulation

- Protected by Damp Proof Membrane (DPM)

- Inverted Flat roof construction?

- multi-layered to minimise rainwater cold bridging

- Needs decrement delay somewhere in the roof element

- Below Ground floor thermal conductivity insulation

Rubber Insulation

Latex Foam

- Invented by mould growth consultants to remove risk of surface condensation in fuel poverty stricken houses

- IWI Internal wall insulation

- Provides the barest minimum of thickness and allows wall papering over

- Offers a degree of thermal comfort

- Thin, okay k value, poor u value

- Same materials as Spitting Image puppet heads

Mixed materials

Papercrete

- Cement and Paper making fibre sludge

- GGBS OPC replacements ideally

Papercrete

- Paper making waste sludge fibres

- Cementitious binder

- OPC Ordinary Portland Cement

- Could be GGBS Ground Granulated Blast Furnace Slag cement

- Could be blended OPC & GGBS

- Very low density

- High thermal mass: Decrement Delay?

- OPC is water and vapour resistant

- Paper sludge fibres are vapour permeable

- How vapour permeable if the end result?

- Strength: ? Similar low strength Hemp-lime blocks

- Connected two companies to try to bring something to market

Cork Diatomeic Earth Render

Diatomeic Powders, Cork, Clay and Lime Plaster/Render

- IWI Internal Wall Insulation or EWI External Wall Insulation

- Premixed thermal plaster

- Ocean floor minerals: Diatomeic Powders

- Cork granules: 0-3 mm

- Hydraulic Lime: NHL 3.5

- Clay

- Vapour permeability: μ= 4

- Breathable: compatible with historic walls

- Capillary water absorption: 0.35 kg/m2.hr (Category W2)

- Fire: Euroclass A2

- Sound absorbing coating

- k value: 0.045 W/mk Winter Insulation

- Density: 360+/-20 kg/m3

- Decrement delay: Summer Insulation

- Inert and recyclable

- Indoor Air Quality: Low VOC emissions

- Manufacturer: Diasen

- Product Reference: Diathonite Evolution

Hemp-lime

- Hemp-lime Hempcrete

- Hemp shiv fibres

- Rapidly renewable plant fibre

- Lime binder

- Very low density

- High thermal mass: Decrement Delay?

- Lime is water and vapour permeable

- Hemp shiv fibres are vapour permeable

- How vapour permeable if the end result?

- Strength: ? Similar low strength Hemp-lime blocks

- NGS Connected two companies to try to bring something new to market with a new non-cementitious binder

Hemp Lime Applications

- Insitu spray on to walls

- Insitu spray into cassette panels

- Insitu compact into diaphram wall cavity

- Insitu ground bearing floor

- Non-loadbearing blockwork

- Loadbearing blockwork ? Add cement?

Tradical Hemp-lime Hempcrete

- Hemp shiv fibres

- Rapidly renewable plant fibre

- Lime binder: Slow set, softer bond, high energy, high carbon

- Cementitious binder added to drive the lime’s hydration

- OPC Ordinary Portland Cement, fast set, strong bond, very high energy, very high carbon

- Aluminium oxide: saponification reaction with cement generated bubbles

- Bubbles add thermal insulation

- Phase Change characteristic

- Very low density

- High thermal mass: Decrement Delay

- Lime is water and vapour permeable

- OPC is water and vapour resistant

- Hemp shiv fibres are vapour permeable

- How vapour permeable if the end result?

- Strength: ? Similar low strength Hemp-lime blocks, very low strength

- Manufacturer: Lhoist

- Product Reference: Tradical

Lightweight Cob

Clay-Straw

Interreg CobBauge Project

- Cob=English, Bauge=French

- Earth (Clay recipe) and straw

- 21st Century Cob (Regulations)

- Traditional Cob is Structure, Thermal mass and weather exclusion

- CobBauge combines: (see previous slide)

- structural mix cob (yellow) with

- light clay straw/hemp insulating mix cob (brown)

Mixed materials Multi-component systems

SIPs Structural Insulated Panels

Structural Insulated Panels SIP

- OSB Oriented Strand Board skins

- Biobased but added chemistry binder

- PUR Polyurethane

- Non-renewable fossil fuel bi-product

- High carbon: adds to climate change

- Toxic in fire

- Panel jointing adhesive: more chemistry

- Good k value for winter

- Poor decrement factor for summer

- High risk of overheating in summer

ISPs Insulated Structural Panels

- Structural Timber cassette panels any insulation fill

- Insulated Structural Panels ISP

- Plywood, chipboard or OSB skins

- Biobased but added chemistry binder

- Any insulation ideally biobased

- Rapidly renewable agricultural bi-product

- High Sequestered carbon: reduce climate change

- Hygroscopic: Moisture management

- Dry Panel jointing or taped joints

- Good k value for winter

- Good decrement factor for summer

- Low risk of overheating in summer

Vacuum Insulated Panel VIP

Vacuum Insulated panels VIP

- Aluminium Foil envelope

- Plastic spherical balls accurately packed with 12 points of contact between each

- Air sucked out of envelop and sealed

- Vacuum in interstices between spheres

- Best ever thermal insulation k value

- No decrement delay

- Sun’s heat passes through vacuum of space without hindrance

Lightweight Thermal Mass

- Dense wood fibre outer layers

- Cardboard honeycomb core

- Cardboard cells contain wax

- Phase change materials (PCM):

- Phases: Solid, Liquid & Gas

- Fluidity: ability to move between phases

- Changing phases: gains or released heat energy

- Wax stores or releases heat energy

- Adds thermal mass to partitions and freestanding screens

- 22:26 Austria: Suggestion

- Reduce 700 mm extruded clay walls to 500 mm

- Add back lightweight thermal mass IWI

Wood Fibre based Systems

- IWI: Wood fibre board with moisture permeable plaster skim

- EWI: Wood fibre board with moisture permeable lime render

Test Yourself

- Where can you use Hydrophobic insulation?

- Where can Hygroscopic insulation be used?

- How does Hygroscopic insulation work when in damp conditions?

- How did you do?

- Hydrophobic in dry wall construction and even in external cavity walls

- Hygroscopic in breathing walls and one in partial fill masonry cavity wall

- Hygroscopic insulation absorbs moisture into the fibre leaving the airspace to insulate

© 2023 NGS GBE GBC GRC

- Brian Murphy ONC HNC Construction, BSc Dip Architecture (Hons+Dist)

- Technician and Architect by Training

- Specification Writer by Choice

- Environmentalist by Actions

- Writer and Educator as a Calling

- Number Cruncher by Necessity

- Greening up my act since 1999

- Founded National Green Specification 2001

- Launched www.greenspec.co.uk 2003

- Created: GBE at https://greenbuildingencyclopaedia.uk 2012 – 2022

- Created: GBL Learning: https://GBELearning.com 2020 – 2021

- Created: GBC at https://GreenBuildingCalculator.uk 2011 – 2022

- E BrianSpecMan@icloud.com

- Twitter: https://twitter.com/brianspecman

- Twitter: https://twitter.com/gbeGreenBuild

- Twitter: https://twitter.com/GBELearning

- LinkedIn: BrianSpecMan https://uk.linkedin.com/pub/brianspecman-murphy/9494492/

- Facebook: BrianSpecMan http://www.facebook.com/brianspecman

- GoogleMyBusiness: National Green Specification

- Pinterest: Brian Murphy • GBE Green Building Encyclopaedia

- Pinterest: https://www.pinterest.co.uk/bmurphy1390/

- National Green Specification

- Instagram: https://www.instagram.com/brianmurphy1811/

- YouTube: https://www.youtube.com/channel/UCOKfss57bwNZeYhGYg30NKg

© GBE GBC GRC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

27th May 2023 – 7th July 2023

Images:

GBE CPD Poster

GBE CPD JP10 Thermal Insulation A04 BRM 060723 S205 PDF Show

GBE CPD

GBE CPD Cover Image

Thermal insulation masterclass

GBE CPD Files

- Handout PDF to print

- Show PDF to view

© GBE GBC GRC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

27th May 2023 – 6th July 2023

See Also:

GBE Future Events

GBE Events

- Overheating CIOB (Event) G#27397

- Overheating and Designing for Summer Comfort (Event) G#9215

- Primitive Materials Future Building (Webinar) G#16202

GBE CPD

CPD Topics N#478

- CDP Topic Refurbishment Retrofit (Navigation) G#1451 N#1419

CPD seminars PDFs

- CaseStudyAngleTownBoatemahWalk PDF Show

- CaseStudyBD+PListed1Barn PDF Show

- CaseStudyWelshPassivhaus PDF Show

- GBE CPD Case Studies G#468 N#474

- CaseStudyParityProjects PDF

- TSB Retrofit for a Future Competition project

- Welsh Passivhaus case study (CPD) N#251

Seminars:

Specification:

- A90 Performance Specification (CPD) G#1377 N#1354

- About Specification (CPD) G#560 N#580

- NBS Building Diagrams PDF Show

- Specification Writing (CPD Lectures Training Coaching) G#15462

- Specifications in the world of NBS Building (CPD) G#4383

- Specification Clause Content (CPD) G#371 N#372

- Specification In NBS World NGS Building PDF Show

- NBS Building Diagrams PDF Show

Materials & Products:

- Green or Violet materials Which do you use (CPD) G#15560

- Violet Materials (Materials) G#963 N#983

- How do GBE Select Products (CPD)

Carbon:

- Jargon Buster Carbon Dioxide (CPD) G#291 N#292

- 57 Carbon and CO2 related terms

- Low Carbon Green Building (CPD)

- Low v High Carbon Lifestyle (CPD) N#307

- Zero Carbon Development Passive Approach (CPD)

Performance:

- Overheating (CPD) G#15750

- SunSpace WinterGarden Conservatory (CPD) G#294 N#295

- Surveys Tests Analysis (CPD Lecture) G#389 N#390

- Zero Carbon Development Passive Approach (CPD)

Refurbishment/Retrofit

- RefurbishmentTSBRetrofitForAFuture (CPD) PDF Show

- Retrofit GreenDeal (CPD) N#339

- Retrofit GreenDeal Risks Rev11 (CPD) N#351

- Retrofit Materials and Methods (CPD)

- TSB Retrofit for a Future Competition project

- Welsh Passivhaus case study (CPD) N#251

GBE Shop CPD

GBE In-House CPD

- CPD Your In-house CPD G#2404

GBE Lectures

- GBE Lecture Courses G#480 N#486

- Subjects

- GBE Lectures Subjects G#715 N#737

- GBE Lectures G#480 N#486

- GBE Lectures Satisfied Customers

- UH Part 1 Year 2 Task Schedule (Course) G#17699

RIBA Part 1 Under Graduate

RIBA Part 1 Year 1 (LSBU 2007-2008) Elements

- (11) Site, Ground, Floor (Lectures) G#2111

- (13.1) Ground Floor (Lectures) G#2112

- (16.4) Groundworks RC Raft Foundation (Lectures) G#2114

- F132 Basements (Lectures) G#269

- (21) Masonry External Walls (Lectures) G#2115

- (21) Other External Walls (Lectures) G#2123

- (21) Timber External Walls (Lectures) G#2116

- (21) Timber Frame (Lectures) G#2117

- (22) Partitions (Lectures) G#2119

- (23) Upper Floors (Lectures) G#2120

- (27.1) Flat Roofs (Lectures) G#2121

- (27.2) Pitched Roofs (Lectures) G#2122

RIBA Part 1 Year 2 2018-2019-2020 (University of Hertfordshire)

- S1 Adopt A Material (Studio Lecture) G#19183 2018-2020

- L1 Building Envelope Principles (Lecture) G#31815 2019/20

- L2 Introduction to Materials (Lecture) G#31821

- L4 External Walls, Openings Windows Doors (Lecture) G#19226 2018/19

- L5 Floors Ceilings Partitions (Lecture) G#31829 2019/2020

- L6A Passive Performance (Lecture) G#32048 2019/2020

- L15 Design and Detailing to Perform (Lecture) G#20475

RIBA Part 1 Year 2 (LSBU 2016/2017)

- Energy Efficiency

- EnergyEfficiency-9H5 PDF Handout

- EnergyEfficiency-S43 PDF Show

RIBA Part 2 Post-Graduate

RIBA Part 2 M Arch Lab 1 University of Hertfordshire 2019-2020

- 1 Sustainability Introduction

- Sustainability Introduction (Lecture) G#31739

- 2 Green Or Violet Insulation Materials

- Green or Violet materials Which do you use (CPD) G#15560

- 3 Low and High Rise Construction

- 3A Low Rise Building

- Low Rise Building (Lecture) G#31778

- 3B High Rise Building

- High Rise Building (Lecture) G#31780

- 4 Air Movement in Building

- Air Movement In Buildings (Lecture) G#31812

- Air Movement in Buildings (CPD) (Navigation) G#2089 N#229

- Lecture Air Movement In Building (Shop) G#11038

GBE Defects

- GBE Loft Insulation (Defects) G#14166

GBE Q&A

- External Wall Insulation (Q+A) G#40828

- Insulating room in roof houses (Q+A) G#40783

- Spray Foam Thermal Insulation (Q+A) G#40648

- Removing Cavity Wall Insulation (Q+A) G#38597

- GBE Overlaying Loft Insulation (Q+A) G#38593

- Primitive Materials Future Building (Q+A) G#16244

GBE Checklists

- GBE E72 Cob Wall Systems (Checklist) G#40387

- GBE K43 Raised Storage Access Systems (Checklist) G#13934

- M21 Insulation With Rendered Finish (Checklist) G#9442

GBE Materials

- Animal (Materials) G#16486

- Primitive Bio-based Material Properties (Materials) G#16471

- GBE Insulation Properties (Materials) G#16067

GBE Primitive

- Primitive Bio-based Material Properties (Materials) G#16471

- Primitive Materials Future Building Offsite Manufacture (OSM) G#16467

- Information needs Primitive materials (Survey) G#16394

- Primitive (Jargon Buster) G#16326

- Primitive Materials Future Building (Q+A) G#16244

- Primitive Materials Future Building (Webinar) G#16202

GBE Issue Papers

- Overheating (Issue Papers) G#145

- Squashed Loft Insulation (Issue Papers) G#13919

- Urban Risks due to Climate Change (Issue Paper) G#12500

CPD Manufacturer’s

- GBE LitEdit LoftZoneCPD A02BRM100117 9H5 PDF handout

- GBE LitEdit LoftZoneCPD A02BRM100117 S39 PDF Show

- GBE LitEdit LoftZoneCPD A02BRM100117 PPTX Show with working hyperlinks

GBE Manufacturer

- Eco Answers Ltd t/a LoftZone G#13890

GBE Suppliers

GBE System

© GBE GBC GRC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

27th May 2023 – 7th July 2023