E10 Insitu Concrete Checklist

GBE > Encyclopaedia > Code > Checklist > E Concrete > G#933 N#951

E10 Insitu Concrete Checklist

About:

Greenwash alert:

- “GGBS is the greenest construction material”

- it might be one of the greenest cement options,

- but that claim is outrageous

- “Concrete can sequestrate carbon dioxide from the atmosphere”

- it can, but its penetration is very shallow, any deeper and it degrades the concrete’s durability and can lead to reinforcement corrosion and failure

- Carbonation of concrete is a severe problem (see below) requiring intensive repair

- “Concrete thermal mass can be used for thermal inertia”

- but the concrete must be ‘on show’ not ‘behind finishes’ to enable any real benefits during prolonged hot spells

- in summer concrete needs to be cooled ‘purged’ overnight to replenish its thermal mass capacity

- in winter heating season they should not be allowed to cool and loose the heat.

- corrugated steel trough permanent formwork soffits to floors prevent exploitation of thermal mass from below

Consider these:

- Lime: in place of or with cement

- Limecrete: on place of concrete

- Hemp-lime: in place of aggregate-cement

- Hempcrete: in place of aggregate-cement concrete

- Specification that ‘require’ rather than ‘permit’ use of lower impact concrete

- GGBS Cement: as an OPC substitute

- Blended GGBS & OPC to maximise GGBS advantages and minimise OPC disadvantages

- Blended GGBS & OPC in silos or 25 kg bags

- Blended GGBS & OPC Concrete from your ready mix supplier

- Secondary Aggregates: the waste from primary aggregate extraction/sieving

- Recycled Aggregates: in place of virgin/primary aggregates

- Recycled concrete aggregate: in place of virgin/primary aggregates

- Recycled clean water

- Thin resilient flooring (e.g. linoleum and rubber): allows the thermal mass to be exploited; warm touch insulating PVC, carpets and underlayment insulate and prevent the heat flow.

Avoid or reduce the use of these:

- Cement (High energy and high carbon dioxide in production)

- Don’t over strengthen concrete unnecessarily

- OPC (Ordinary Portland Cement) accounts for 8-10% of global manmade CO2 production so its carbon generating in the first place, when we should be cutting back.

- PFA cement (and scroll down to fly ash)

- Concrete ingredient cement OPC

- Concrete

- Concrete made with OPC

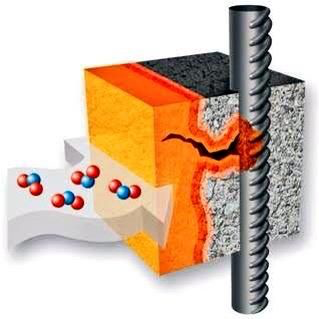

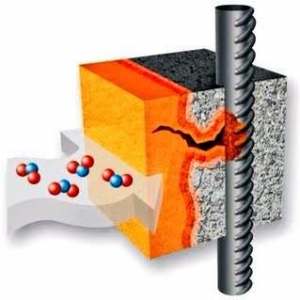

- Carbonation of Concrete

- I was told by my engineer carbonation of concrete was bad for concrete so he coats concrete to prevent this happening,

- Now the concrete sector marketing arm want us to account for carbon sequestration in concrete.

- We cannot if its coated, but not every engineer coats concrete

- Carbon sequestration in concrete surface is effectively the same as concrete carbonation

- Carbonation can only be assumed to affect the first 5 mm. or so over the exposed surface area or it starts to effect the protection to reinforcement potentially leading to failure

- Dodgy marketing.

-

- Carbonation in concrete reduces the alkalinity that protects ordinary steel reinforcement from corrosion.

- Once the carbonated layer reaches reinforcement, it’s at risk of corrosion, and as corrosion products are more bulky than the raw steel, the concrete spalls, and you then get into expensive repairs – both in cost and environmental impact of the materials used.

- And as reinforcement is generally as near to the surface as possible to maximise strength, there’s not much carbonation that can take place before you start to get into failure conditions.

- Of course you could galvanize the reinforcement, after bending (energy-intensive hot-dip process) or use stainless steel / GRP / other composite reinforcement

- All of which rather defeats the point of encouraging carbonation in the first place.

Resource Efficiency Issues:

- Reduce: Don’t order more than is needed. Don’t over strengthen the mix.

- Reclaim:

- Reuse: Formwork, use tough reusable formwork

- Recycle: Concrete structures a Recycled Concrete Aggregate (RCA) as hardcore, as sub-base, as piling mat

- Recycle: Reinforcement steel wires and mesh

- Recycle: Steel trough permanent formwork

- Recover:

Waste Issues:

- Waste group:

- Inert (unless contaminated or failed due to carbonation, alkali-silica reaction, etc.)

- Deleterious:

- Concrete that has failed e.g. suffered carbonation, alkali-silica reaction,

- should not be recycled

- should not go to inert waste landfill in case it gets mined in the future to be recycled

- Hazardous:

- Waste statistics

- Waste:

- Don’t over order more than you need

- Concrete mixer washings are diluted concrete flushed out of the mixing drum to ensure its clean for the following charge

- Use the last unused concrete to make another meter of site path or road or base

- End of Life options

- Healthy concrete can and is recycled (crushed) on site in readiness for the following building

- Steel reinforcement bars can and should be extracted for recycling.

- Demolished building rubble can be used as a piling mat to help prevent piling rigs sinking into the site

Health and safety issues:

- Cement powder is fine and can be breathed into the lungs, see precautionary principle

- Cement with water is alkali and can affect skin and eyes, contact should be avoided

- Unset concrete is alkali and can affect skin, contact should be avoided

- Concrete vibrators can have detrimental effects on operatives hands and limbs

Maintenance issue:

- Exposed concrete and normal poor detailing usually results in unsightly staining due to air pollutants and rainwater running uncontrolled down building facades.

- Concrete repairs are labour intensive, chemically intensive with high embodied energy and carbon

Precautionary principle:

- Avoid breathing in very fine cement dust in case its carcinogenic

- Avoid hand contact unless protected by barrier creams or gloves first

Information sources:

- Aggregain (WRAP site now moved to CIRIA)

- Resource Efficiency Knowledge base (CIRIA) Requires Sign-in

- Concrete Centre (CC)

© GBE NGS ASWS BrianMurphy aka BrianSpecMan

6th May 2013 – 22nd March 2019

E10 Insitu Concrete Checklist

Images:

Concrete Carbonation

© GBE NGS ASWS BrianMurphy aka BrianSpecMan

19th December 2018

E10 Insitu Concrete Checklist

See Also:

GBE Greenwash

- Polished Concrete Floors (Greenwash) G#737 N#759

GBE Jargon Buster

GBE Jargon Buster Initials Abbreviations Acronyms

- CC

- CIRIA

- GGBS

- OPC

- PFA

- WRAP

GBE Jargon Buster Entries

- Blended Cements

- Blended GGBS & OPC

- Carbonation of Concrete

- Cement

- Concrete

- Concrete ingredient cement

- Concrete made with OPC

- Ground Granulated Blast-furnace Slag (GGBS) Cement

- Hemp-lime

- Hempcrete

- Lime

- Limecrete

- OPC substitute

- Ordinary Portland Cement (OPC)

- PFA cement

- Primary aggregate

- Pulverised Fuel Ash (PFA)

- Recycled Aggregates

- Recycled concrete aggregate

- Recycled clean water

- Secondary Aggregates

- Thin resilient flooring

- Virgin Aggregates

GBE Links:

- Aggregain (WRAP site now moved to CIRIA)

- Resource Efficiency Knowledgebase (CIRIA)

- Concrete Centre (CC)

© GBE NGS ASWS BrianMurphy aka BrianSpecMan

6th May 2013 – 22nd March 2019