Timber Comeback: Why Engineered Wood Is the Future of Low-Carbon Construction

GBE > Advertise > Collaborate > Services > Guest Posts > G#42699

About:

Timber Comeback: Why Engineered Wood Is the Future of Low-Carbon Construction

Introduction

- As the built environment faces mounting pressure to decarbonise, engineered timber is re-emerging as one of the most promising materials for sustainable construction. Once dismissed in favour of steel and concrete, timber — especially in its engineered forms such as:

- CLT (Cross-Laminated Timber),

- Glulam, and

- LVL (Laminated Veneer Lumber)

- — is now redefining what it means to build responsibly.

- Its low embodied carbon, renewable origins, and capacity to store carbon throughout a building’s lifespan make it a natural ally in tackling the climate crisis.

- In the United Kingdom and across the European Union, policymakers, architects, and developers are revisiting the role of timber.

- The shift is not nostalgic; it is strategic — grounded in evidence-based sustainability principles and modern engineering innovation.

The Embodied Carbon Challenge

- Globally, the built environment accounts for around 40% of total carbon emissions, with embodied carbon — the emissions from materials production, transport, and assembly — forming a substantial portion.

- Concrete and steel, though structurally dominant, are carbon-intensive due to their energy-heavy production processes.

- Engineered timber, by contrast, acts as a carbon sink.

- Every cubic metre of wood stores roughly one tonne of carbon dioxide, offsetting emissions that would otherwise enter the atmosphere.

- When responsibly sourced, timber also ensures the circularity of materials — fitting seamlessly into a regenerative, low-waste model of construction.

- Unlike carbon offsetting schemes that merely balance emissions elsewhere, timber offers direct sequestration within the built environment — carbon literally locked into the building’s frame.

From Solid Wood to Engineered Innovation

- Traditional timber structures were once limited by wood’s natural weaknesses — moisture sensitivity, dimensional instability, and limited spans.

The innovation of engineered wood overcame these barriers. - Cross-Laminated Timber (CLT):

CLT panels are made by gluing layers of timber at right angles, creating exceptional strength and stability. They serve as structural walls, floors, and roofs — enabling mid- to high-rise timber construction. - Glulam (Glued Laminated Timber):

Glulam uses multiple bonded layers of timber to achieve long spans with minimal material weight. It offers design freedom similar to steel while maintaining a fraction of its embodied carbon. - Laminated Veneer Lumber (LVL):

LVL combines thin wood veneers into high-performance components with excellent load-bearing properties. It’s used in beams, columns, and trusses — proving that timber can compete structurally in commercial buildings. - These materials share a key advantage: they can be prefabricated off-site with precision, reducing waste, labour time, and transportation emissions.

Healthy and Environmental: Aligning with HERACEY™

The HERACEY™ principles — Healthy, Environmental, Resourceful, Appropriate, Competent, Effective, and Yardstick — define GBE’s sustainability standards. Engineered timber meets or exceeds many of these benchmarks.

- Healthy:

Timber is free from high-chemistry components commonly found in plastics or synthetic composites. When manufactured with low-VOC adhesives, it supports superior indoor air quality and occupant wellbeing. - Environmental:

Timber’s embodied energy is among the lowest of all mainstream structural materials. Sustainably managed forests ensure the carbon absorbed during growth exceeds the emissions during processing. - Resourceful:

Engineered wood maximises the use of small-diameter logs and offcuts, promoting a circular economy and reducing raw material waste. End-of-life timber can be reclaimed or repurposed. - Appropriate:

Timber’s lightweight nature makes it suitable for retrofitting and upward extensions — critical in urban environments where additional structural load is a constraint. - Competent:

CLT and Glulam are rigorously tested to European standards (EN 14080, EN 16351) and are increasingly certified under environmental product declarations (EPDs). - Effective:

Engineered timber doesn’t just reduce emissions — it achieves step-change performance, enabling carbon-negative buildings when combined with renewable energy and bio-based finishes. - Yardstick:

Life-cycle analysis (LCA) tools confirm its carbon advantage, making it measurable, verifiable, and benchmarkable.

Carbon Accounting: Why Timber Wins

- Concrete and steel depend on high-temperature industrial processes, releasing vast quantities of CO₂ during production.

- Even with technological advancements like carbon capture, their emissions remain difficult to eliminate.

- By contrast, engineered timber’s production process involves minimal fossil fuel input.

According to recent BRE and EPD data, the embodied carbon of CLT can be up to 80% lower than reinforced concrete on a comparable structural basis. - Furthermore, when the timber is sourced from FSC® or PEFC-certified forests, the carbon cycle remains regenerative — harvested trees are replaced by new growth, continuously sequestering carbon.

- Timber’s carbon-back period — the time it takes for stored carbon to offset production emissions — can be as short as a few months. This metric aligns perfectly with GBE’s preference for carbon-back analysis over financial payback models.

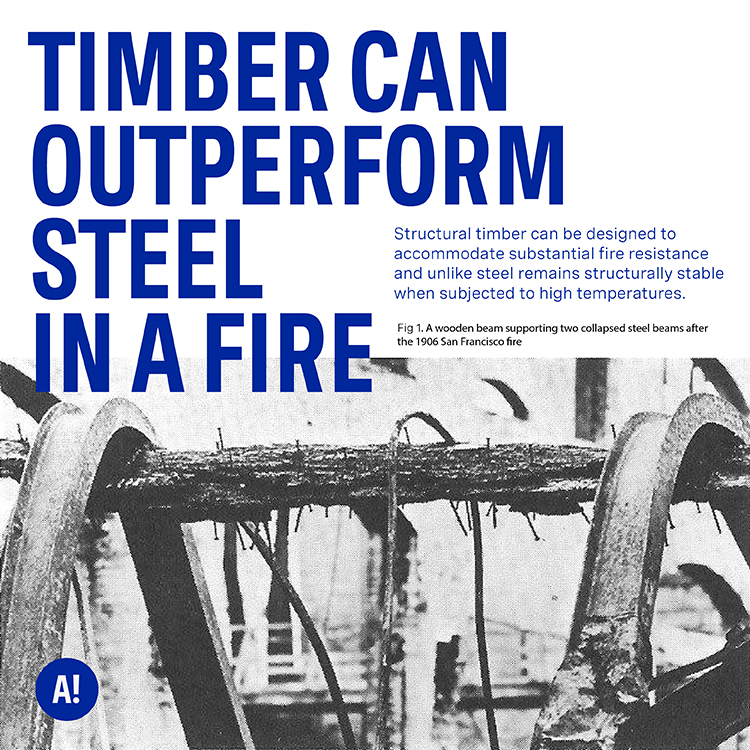

The Fire Safety Question

- Fire resistance remains a common misconception around timber buildings.

- In reality, engineered timber chars predictably and maintains its structural integrity longer than unprotected steel under equivalent heat conditions.

- Modern fire testing standards demonstrate that CLT and Glulam, when correctly detailed, can meet or exceed building regulations. Encapsulation strategies, sprinkler systems, and compartmentalisation ensure compliance without undermining sustainability goals.

- In the UK, regulatory frameworks are evolving to support performance-based fire design, acknowledging the proven resilience of mass timber systems.

Circularity and Resource Efficiency

- A cornerstone of low-carbon construction is designing for deconstruction. Engineered timber structures are typically assembled with mechanical fixings rather than chemical adhesives, allowing disassembly and reuse.

- Prefabrication also allows waste reduction at source — factories can achieve up to 98% material efficiency, with offcuts recycled into panels or biomass energy.

This resource-conscious approach supports the Resourceful and Effective dimensions of HERACEY™. - At the end of a building’s life, timber components can be:

- Reused in new buildings,

- Recycled into secondary materials,

- Or used for clean energy recovery.

- This lifecycle continuity sets timber apart from high-embodied carbon materials that often end in landfill.

- Socioeconomic and Ethical Dimensions

- Sustainable forestry supports rural employment and fosters ethical supply chains.

- Local timber sourcing reduces transport emissions while strengthening regional economies — aligning with GBE’s Social and Ethical sustainability values.

- Furthermore, timber construction encourages upskilling in modern methods of construction (MMC), digital design, and precision manufacturing — advancing workforce competence and construction quality.

- From an ethical standpoint, choosing renewable bio-based materials demonstrates planet-first decision-making, shifting away from petrochemical dependency and “profits before people” approaches.

Design Opportunities and Architectural Aesthetics

- Engineered timber offers architects unique creative potential — warm aesthetics, biophilic benefits, and structural elegance. Exposed timber interiors contribute to occupant comfort and wellbeing by regulating humidity and evoking natural environments.

- Hybrid systems, where timber works alongside steel or concrete, combine performance strengths while optimising material use — an Appropriate and Competent design strategy.

- Leading European projects like Dalston Works (London) and Sara Kulturhus (Sweden) showcase the scalability of timber — from social housing to high-rise civic buildings — proving that sustainability and modern design are no longer mutually exclusive.

Challenges and the Way Forward

Despite its advantages, timber adoption faces hurdles:

- Limited supply chain maturity in the UK compared to Europe

- Misconceptions around fire and durability

- Insurance and regulatory constraints

However, initiatives such as the Timber in Construction Roadmap (2023) and RIBA’s 2030 Climate Challenge are accelerating acceptance.

Government-backed research, EPD databases, and circular economy policies further validate timber’s credentials as a mainstream low-carbon solution.

In future, digital tools like the Green Building Calculator and environmental product declarations will make it easier to quantify and benchmark carbon savings, enhancing transparency across the industry.

Conclusion

- Engineered timber represents more than a material comeback — it’s a revolution in how we think about building.

It satisfies GBE’s HERACEY™ framework: it’s healthy, environmental, resourceful, appropriate, competent, effective, and measurable. - As the UK and EU push towards net-zero carbon targets, engineered wood stands out as the material capable of delivering immediate carbon reductions, long-term sustainability, and architectural excellence.

By embracing timber not as an alternative but as a primary structural solution, we can create buildings that store carbon, support communities, and sustain the planet — one beam at a time.

GBE Team Guest Author

Name: Preeth Vinod Jethwani

© GBE GBC GRC GIC GGC GBL NGS ASWS Brian Murphy aka BrianSpecMan ******

13th January 2025

Images:

GBE Team Guest Author

Name: Preeth Vinod Jethwani

Name: Preeth Vinod Jethwani

© GBE GBC GRC GIC GGC GBL NGS ASWS Brian Murphy aka BrianSpecMan ******

13th January 2025

See Also:

GBE Guest Posts

- Guest Post (Collaborate) G#40818

- Pultrusion (Guest Post) G#40852

- Storage (Guest Post) G#40818

- Biophilia (Jargon Buster) G#16602

- Growing Your Own (Guest Post) G#42187

- Sustainable Renovation Process (Guest Post) G#42350

- Digital Data Carbon Footprint (Guest Post) G# 42296

- Access ECO4 (Guest Post) G#42579

- Future of Sustainable Insulation: Natural Materials Over Plastics (Guest Post) G#42605

- Circular Construction: Designing for Deconstruction and Material Reuse (Guest Post) G#42629

- Eco-Refurbishment: Turning Old Buildings into Energy-Efficient Homes (Guest Post) G#42642

- Bio-Based Insulation and Its Role in Carbon Reduction (Guest Post) G#42658

- Beyond Bamboo: Exploring Rapidly Renewable Materials for UK Builders (Guest Post) G#42694

- Timber Comeback: Why Engineered Wood Is the Future of Low-Carbon Construction (Guest Post) G#42699 (this post)

GBE HERACEY™

- GBE HERACEY (Jargon Buster) G#1429 N#1399

- GBE HERACEY Healthy (Jargon Buster) G#1896 N#1753

GBE Other’s Stuff

- Other’s News G#935 N#953

- Other’s Campaigns (Navigation) G#976 N#997

- Other’s Newsletters (Navigation) G#682 N#704

- Other’s Blogs G#906 N#926

- Other’s Surveys G#970 N#991

GBE Brain Dumps

- EcoHomes What does the future look like (Brain Dump) G#40732

- How to Design Sustainably (Brain Dump) G#40730

- MMC Modern Methods of Construction (Brain Dump) G#39443

- Sustainable Rail UN SDG (Brain Dump) G#39377

- Greening Offices Biophilia (Brain Dump) G#39346

- Greening Offices UN SDG (Brain Dump) G#39342

- Greening Offices Post COVID (Brain Dump) G#39335

- Building Performance Aspects (Brain Dump) G#21255

- Blockchain Timber Chain of Custody (Brain Dump) G#20312

- Landscape Resource Efficiency (Brain Dump) G#643 N#665

- Product Data Golden Thread (Brain Dump) G#39241

GBE Brainstorms

- House NI 1960s EnerPHit Upgrade (Brainstorm) G#16288

- Future Facing Environmental Bathrooms (BrainStorm) G#15701

- Stone Barn Conversion Thermal Insulation (BrainStorm) G#14897

- Improving U values by Substitution (Brainstorm) G#13507

- 3 Houses (Brainstorm) G#7851

- Semi Basement (Brainstorm) G#7393

- Sommerfield One Off House (Brainstorm) G#760 N#782

GBE Issue papers

- Overheating (Issue Paper) G#145

- Squashed Loft Insulation (Issue Paper) G#13919

- Urban Risks due to Climate Change (Issue Paper) G#12500

- Phthalates in PVC Flooring Profiles (Issue Paper)

- Biophilic Design (Issue) G#16587

- Indoor Air Quality IAQ (Issue) G#1119 N#1135

GBE Projects

© GBE GBC GRC GIC GGC GBL NGS ASWS Brian Murphy aka BrianSpecMan ******

13th November 2025