About:

Banner

- Pay for English Oak and get TR26 Softwood

Project Case Study

- Project: Gloucester Centre Redevelopment

- Land owner: By this stage the land had passed from NHS to Homes England

- Client’s Advisor: Savills Cambridge Office

- Observers: Gloucester Centre Redevelopment Action Group

- Parish Councillors & Residents

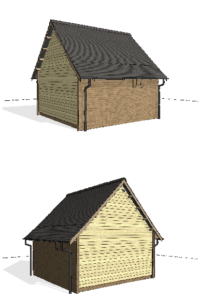

Bat Barn FSC Timber Substitution

- We may wish to respond to the Savills email/letter with any or all of the following and you may wish to communicate this wider than Savills:

- The words used in Savills’ response suggest a potential misunderstanding, which may be misleading and needs clarification and needs to be expanded upon.

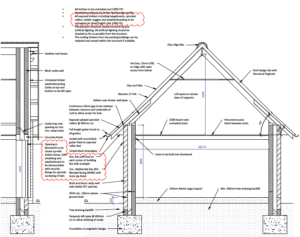

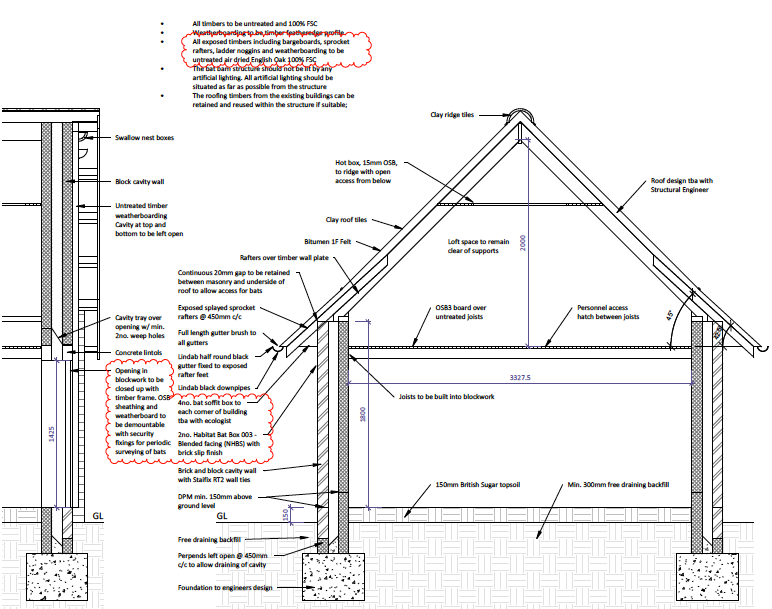

Drawing Specification:

- All timbers to be untreated and 100% FSC

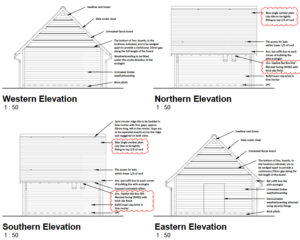

- All exposed timbers including barge boards, sprockets, rafters, ladder noggins and weatherboarding to be untreated, air dried English Oak, 100% FSC.

Justification:

- The reason for this choice is to provide durability (English oak) without preservative treatment which could adversely affect the bat’s health.

- Preservative treatments are after all designed to kill timber from trees so they are no longer a good habitat, food or water source for wildlife, insects, fungus and mould.

Site Observations

- What was seen on site was Timber roof trusses, Gable ladders, Timber studs (but there is none in the barn) possibly for the splayed sprocket rafters at eaves.

- Pasquill apprears to be the fabricator of the Trusses and the gable ladders (their labels were on the gable ladders)

- Despite extensive labelling and digital printed markings on trusses and gable ladders, no evidence existed that these timber are FSC.

- None of the timbers appeared to be treated (No green or Blue tinges) but clear treatments may have been used.

- All of the timbers including the trussed rafters looked like simple softwoods.

- The trussed rafters and the gable ladders noggin are marked as TR26 (normally associated with softwood for trussed rafters)

Inappropriate off-site prefabrication

- Changing from on-site in-situ cut timber roof to trussed rafter

- Increases factory made components potentially reducing on site waste

- Simplifies the structure of the walls and roof

- Prevents future modification of the roof

- to remove the bottom chord

- to make room for the bats that exist on site

- that are to be saved by this barn,

- but currently are not catered for

- by this construction of roof and floor geometry.

TR26 Timber

- Taken From Pasquill’s own website:

- https://www.pasquill.co.uk/what-is-tr26-timber/

- The Characteristics of TR26 Timber

- TR26 timber is classified as a sustainable source of timber in accordance with the BS EN 14081. It is kiln-dried and planed all round. The timber is lighter in weight but this does not compromise the strength capabilities that it has. It is designed to improve dimensional stability, all whilst being regularised to a consistent finish.

- What Does Pasquill Use TR26 Graded Timber for?

- Here at Pasquill, we use TR26 timber for all our roof truss products as we believe that it’s the strongest and most structurally reliable material we can offer. All our components are manufactured using high-quality PEFC™ TR26 grade timber joined together with MiTek steel connection plates.

Response Observations Investigations:

- So unless thais consignment has been made to a non-standard procedure

- (they are ISO 9001 and ISO 14001 accredited)

- the above fails to meet the specification on a number of counts:

- TR26 is softwood not hardwood and not English Oak

- so may be strong enough

- but will not be durable enough for this application and

- will have a shorter than desired life expectancy

- It is kiln dried not air-dried as specified

- so not as environmentally sound a choice as the specifier intended

- It is PEFC (at Chorley Lancashire and 8 other site (BMT PEFC-0239 valid to 2025) not FSC certified

- Neither certificate expressly refers to trussed rafters

- Despite government departments instructions,

- PEFC is not equivalent to FSC,

- PEFC was set up in protest against FSC high standards and

- PEFC wants FSC to reduce theirs to match PEFC’s

- Only their Bodmin Branch (FSC TT-COC-003196.P valid until Jan 2025) provides trussed rafters (not listed in FSC certificate) FSC certified only on request (according to website page)

- Timber studs are not normally treated timber so they are untreated softwood, and of small section

- so may not be strong enough and

- will not be durable enough for this application and

- will have a shorter than desired life expectancy

- Other timbers yet to be procured, their specifications

- must not be compromised by further on-site meetings with the ecologist,

- who may not understand all aspects of building,

- who is not the client,

- not the designer/specifier,

- not the Planning Authority and

- should not be permitting a reduction in specification.

3rd Party Certification

- Savills Letter: “the roofing timbers which are to FSC standard”

- A simple statement by a first party (Fabricator or trussed rafters) is not evidence.

- Since Savills did not make the trusses they are not even the first party but a fourth party

- This second party (Client: Homes England?) Should not have to accept the word of the first or fourth party

- We (Councillors and residents) are not convinced, even by a signed letter by a fourth party.

- Normal procedure is to see independent third party (BM TRADA in this case) evidence (FSC TT-COC-003196 valid until Jan 2025)

- In this case FSC Certification of forest/plantations and FSC certification of Chain of Custody.

“… which are to FSC standard …”

- FSC is not a standard that timber is made to.

- Trees grow and follow their own DNA rules (unless genetically modified) not FSC rules

- FSC Is Forest Stewardship Council Certification

- It is about independently inspected sustainable forestry management (preferably sustainable plantation management, as long as forests were not felled to make way for the plantation)

- It is about evidential certification that the timber came from an FSC certified forest or plantation.

- It is also about independently inspected evidential FSC Chain of Custody certification from the FSC certified forest/plantation via transports, mills, seasoners/driers, treatment works, to the timber stockist, or the final timber processor/maker or even to an FSC certified construction site.

- Its purpose is to ensure that the timber is not swapped out along the supply chain with non-FSC certified timber, so that the customer gets what was asked for.

- Since the timber is to be English Oak (Preferably UK grown) its supply chain may be relatively short (fewer parties along the supply chain)

- Since oak is durable it does not need to be treated, it is to be seasoned by air-drying (less parties along the supply chain)

Appropriate response?

- The appropriate response to our concern would be for the fabricator to disclose the FSC certification, not a fourth party say ‘the roofing timbers which are to FSC standard’

- It is imperative that the actual FSC Certification for the actual timbers is provided.

- And for all of the timbers brought to site so far and in future.

‘FSC Standard (they are not exposed)’

- This suggests that FSC standard and Exposure may be related in the mind of the author.

- They are not.

Exposure

- Yes, the roof trusses are to be covered by roofing tiles and bitumen roofing felt so not exposed to direct rain

- However the rafters do extend beyond the walls and are exposed to external conditions including external temperature and precipitation (Mist, Fog, Rain, condensation, wind driven rain,)

- The bat barn to be effective have entry and exit holes for bats and birds so the interiors are exposed to external conditions minus the rain, modified by the microclimate inside.

- Winter night times will be as cold and damp as the outside.

- Timbers need to be durable enough for the conditions of these applications or will have a short life expectancy.

The Gable ladder

- Savills’e Letter: “The ladder noggin is a template only and will be swapped out for the Oak product”

- Problems here:

- Temporary works need not be to the same high durability or strength specification as the permanent works

- But will ideally need to be the same tolerance specification.

- And will want to be to the same environmental specification (FSC)

- Temporary works to be swapped out by permanent works is a considerable waste of resource and more stuff to send to landfill or burn on site without heat recovery.

- The worst position in the waste Hierarchy

- The evidence suggests this ladder is to the same specification as the trussed rafters.

- So is trussed rafter (Permanent works) less than specification or is the ladder (temporary works) more than specification?

- By installing the temporary works in the gable walls accurately its removal may damage the permanent works walls.

- Are the contractors hoping that nobody will notice if the do not remove the temporary works and leave it in permanently?

Unilateral Compromise for profits

- Somebody is paying for air dried untreaed English Oak and getting kiln dried TR26 Softwood

- All of the above suggest the contractor is compromising the specification to increase profit margins at the risk of compromising the life expectancy of the bat barn.

- This does not bode well for the bats that may make use of it.

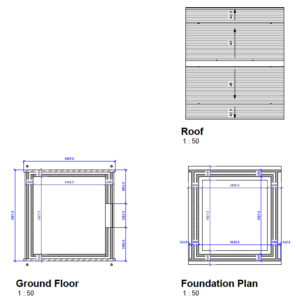

- The significant compromise in the size of the barn interior dimensions, 50% below BCT published recommendations means it does not fit some species of bat it was intended to rehouse.

- In addition we noticed that the June 2020 masterplan puts the bat barn right next to the public footpath/cycleway where it will be at risk of interference by inquisitive humans and their pets.

- It just gets worse.

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

23rd February 2021

Images:

Bat barn

FaceBook Group Page

Gloucester Centre Residents FaceBook Page

Project

Pinterest Section Gloucester Centre Site

Development Public Displays

Pinterest Section Public Display

Residents Tree Survey

Pinterest Section Tree Survey

Development Outline Planning Application

Pinterest Section Outline Planning Application

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

23rd February 2021

Bat Barn FSC Timber Substitution

See Also:

GBE Case Studies

GBE Building Case Studies

GBE Objection

- Ward Councillor (Objection) G#38967

- Tree Felling (Objection) G#38325

- Gloucester Centre Demolition (Objection) G#38285

- Bat Barn Bat Box Post (Objection) G#38145

- Gloucester Centre Redevelopment (Objection) G#28968

GBE Events

- Good Homes Alliance 2020 Annual Conference on Biodiversity

GBE CPD Topic

- Biodiversity CPD Topic (Navigation) G#568 N#588

GBE CPD

- SPAB STBA Conference 2020 (Event) G#38634

GBE Information

- National Policy Framework

- Local Plan

- Local Plan Improvement Campaign

- Climate Emergency Declaration

- Climate Emergency Response

GBE Jargon Buster

© GBE GBC GBL NGS ASWS Brian Murphy aka BrianSpecMan **

23rd February 2021 – 29th March 2021